Octopus oligopeptide capable of promoting synthesis of breast casein and preparation method and application of octopus oligopeptide

A casein and lactation-promoting technology is applied in the field of octopus oligopeptide for promoting the synthesis of breast casein and its preparation, and achieves the effects of good development value, improved expression level and growth promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

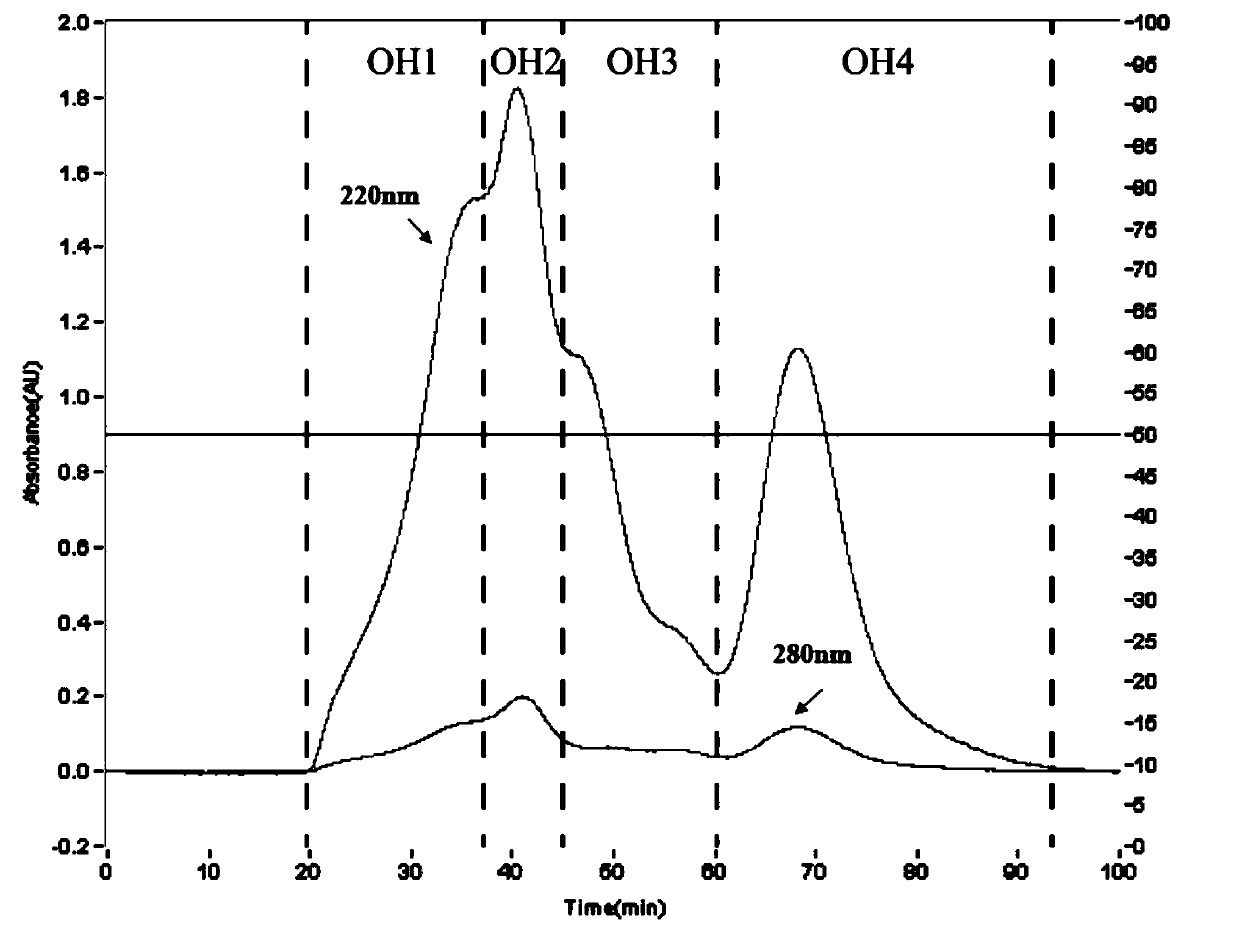

[0026] Preparation of octopus oligopeptide: Wash the fresh octopus, cut into small pieces and grind it with a meat grinder, add deionized water according to the ratio of material to liquid 1g / 2mL, add neutral protease 3000 U / g for enzymatic hydrolysis, pH The value is 6.5, shaken in a constant temperature water bath at 55°C for 5 hours, inactivating enzymes in a boiling water bath for 10 minutes, centrifuging at 10000r / min at 4°C for 30 minutes at a low temperature, taking the supernatant, ultrafiltering the supernatant with a 5kDa ultrafiltration membrane, taking the filtrate to concentrate, and then using The macroporous adsorption resin DA201-C is desalted, concentrated, separated by Sephadex G-25, and eluted with distilled water. The separation spectrum is as follows: figure 1 As shown, the first group of peak samples (OH1) were enriched, concentrated, and freeze-dried to obtain octopus oligopeptides.

[0027] Correspondingly, in the above steps, the macroporous adsorption...

Embodiment 2

[0029] Preparation of octopus oligopeptides: Wash fresh octopus, cut into small pieces and use a meat grinder to homogenate and grind, add deionized water at a ratio of 1g / 3mL to liquid, adjust the pH value to 8.5 with NaOH, and add alkaline protease 2000 U / g enzymatic hydrolysis, 60°C constant temperature water bath shaking for 6h, boiling water bath to inactivate enzyme for 10min, 10000r / min, 4°C low temperature centrifugation for 30min, take the supernatant, ultrafilter the supernatant with a 5kDa ultrafiltration membrane, take the filtrate and concentrate , then desalted with macroporous adsorption resin DA201-C, concentrated, separated with Sephadex G-25, eluted with distilled water, enriched the first group of peak samples (OH1), concentrated, and freeze-dried to obtain octopus oligopeptides.

Embodiment 3

[0031] Preparation of octopus oligopeptides: Wash fresh octopus, cut into small pieces and use a meat grinder to homogenate and grind, add deionized water according to the ratio of material to liquid 1g / 4mL, adjust the pH value to 8.0 with NaOH, add alkaline protease 4000 U / g enzymatic hydrolysis, shaking in a constant temperature water bath at 50°C for 4h, inactivating the enzyme in a boiling water bath for 10min, centrifuging at 10000r / min at 4°C for 30min at low temperature, taking the supernatant, ultrafiltering the supernatant with a 5kDa ultrafiltration membrane, and filtering the filtrate Concentrate, then desalt with macroporous adsorption resin DA201-C, concentrate, then separate with Sephadex G-25, elute with distilled water, enrich the first group of peak samples (OH1), concentrate, freeze-dry to obtain octopus oligopeptide .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com