Fiber-reinforced random copolymerization polypropylene composite pipe and preparation method thereof

A random copolymerization and fiber-reinforced technology, applied in the directions of plant fibers, fiber processing, chemical instruments and methods, etc., can solve the problems of exceeding the standard height of floor decoration, truncation of steel meshes, and high pipelines, so as to improve the pressure resistance performance, Improve low temperature impact performance, improve wear resistance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

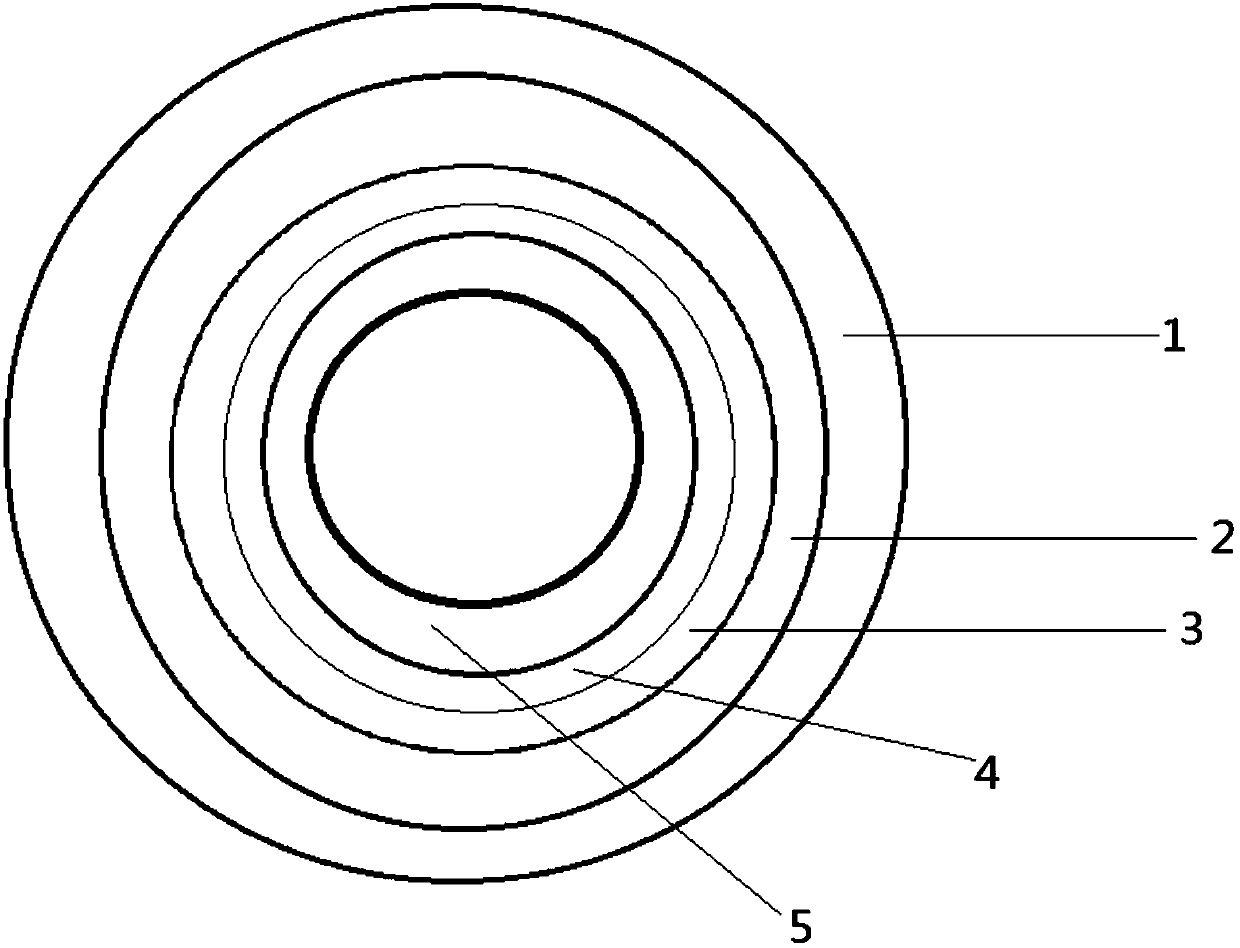

[0076] Please see attached figure 1 , a fiber-reinforced random copolymerized polypropylene composite pipe and a preparation method thereof, is characterized in that it comprises an outer layer, an intermediate layer and an inner layer, and an intermediate layer 3 is arranged between the outer layer 5 and the inner layer 1; between the outer layer and the intermediate layer A polyphenylene sulfide fiber reinforcement layer 4 is arranged between the layers, and a basalt fiber compression layer 2 is arranged between the middle layer and the inner layer.

[0077] A wear-resistant coating is provided on the outer layer, which improves the wear resistance and service life of the pipe.

[0078] The material of the wear-resistant coating is quartz sand particles, which are adhered to the wear-resistant coating through a cross-linking agent.

[0079] The thickness of the wear-resistant layer is 1-10 mm.

[0080] The thickness ratio of the outer layer, middle layer, inner layer, poly...

Embodiment 2

[0112] A fiber-reinforced random copolymerized polypropylene composite pipe and a preparation method thereof, characterized in that it comprises an outer layer, an intermediate layer and an inner layer, an intermediate layer is arranged between the outer layer and the inner layer; Polyphenylene sulfide fiber reinforced layer, basalt fiber compression layer is set between the middle layer and the inner layer.

[0113] A wear-resistant coating is provided on the outer layer, which improves the wear resistance and service life of the pipe.

[0114] The material of the wear-resistant coating is quartz sand particles, which are adhered to the wear-resistant coating through a cross-linking agent.

[0115] The thickness of the wear-resistant layer is 1-10 mm.

[0116] The thickness ratio of the outer layer, middle layer, inner layer, polyphenylene sulfide fiber reinforced layer, and basalt fiber compression layer is 1:1:1:1:1.

[0117] The material of the outer layer is antibacteri...

Embodiment 3

[0149] A fiber-reinforced random copolymerized polypropylene composite pipe and a preparation method thereof, characterized in that it comprises an outer layer, an intermediate layer and an inner layer, an intermediate layer is arranged between the outer layer and the inner layer; Polyphenylene sulfide fiber reinforced layer, basalt fiber compression layer is set between the middle layer and the inner layer.

[0150] A wear-resistant coating is provided on the outer layer, which improves the wear resistance and service life of the pipe.

[0151] The material of the wear-resistant coating is quartz sand particles, which are adhered to the wear-resistant coating through a cross-linking agent.

[0152] The thickness of the wear-resistant layer is 1-10 mm.

[0153] The thickness ratio of the outer layer, middle layer, inner layer, polyphenylene sulfide fiber reinforced layer, and basalt fiber compression layer is 1:1:1:1:1.

[0154] The material of the outer layer is antibacteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com