A method for purifying and melting nickel-based superalloy master alloy

A technology for nickel-based superalloy and master alloy, which is applied in the field of pure smelting of alloys and nickel-based superalloy master alloys, and can solve the problems of high cost and narrow application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

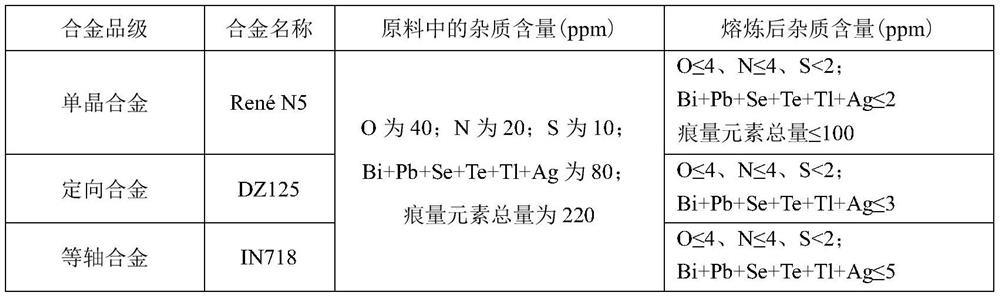

[0017] The present embodiment prepares the second generation nickel-based single crystal superalloy René N5 according to the following steps:

[0018] Step 1, cloth and alloy melting:

[0019] The raw materials are processed to make the surface clean and metallic, and dried at 100°C for 20 hours. According to the composition of René N5 single crystal alloy, in the crucible according to the order of 30% Ni, 100% Co, 100% Cr, 100% Mo, 30% C, 100% Ta, 100% W, 30% Ni raw material order from bottom to top.

[0020] When the pressure rise rate is less than 0.13Pa / min and the vacuum degree is less than 1.3Pa, the electric melting starts. In the initial stage, a stepped power increase mode is adopted (frequency is 30-50kW / 10min until the rated power melts), and the remaining Ni and C are added during the melting process. After the primer is melted, heat until it melts. The whole melting process takes about 70-90min.

[0021] Step 2, a refining process:

[0022] After the bottom m...

Embodiment 2

[0030] The present embodiment prepares oriented nickel-based superalloy DZ125 according to the following steps:

[0031] Step 1, cloth and alloy melting:

[0032] The raw materials are processed to make the surface clean and metallic, and dried at 100°C for 20 hours. According to DZ125 oriented alloy composition, in the crucible according to 30% Ni, 100% Co, 100% Cr, 100% Mo, 35% C, 100% Ta, 100% W, 30% Ni raw material order from bottom to top.

[0033] When the pressure rise rate is less than 0.13pa / min and the vacuum degree is less than 2pa, the electric melting starts. In the initial stage, a stepped power increase mode is adopted (frequency is 30-50kW / 10min until the rated power melts), and the remaining Ni and C are added during the melting process. The whole melting process takes about 110-130min.

[0034] Step 2, a refining process:

[0035] After the bottom material is melted, the temperature is controlled at 1560±10°C, and the low-temperature refining stage is carri...

Embodiment 3

[0043] The present embodiment prepares equiaxed nickel-based superalloy IN718 according to the following steps:

[0044] Step 1, cloth and alloy melting:

[0045] The raw materials are processed to make the surface clean and metallic, and dried at 100°C for 17 hours. According to the IN718 alloy composition, the crucible is distributed in the order of 25% Ni, 100% Fe, 100% Cr, 100% Nb, 100% Mo, 40% C, and 40% Ni raw materials from bottom to top.

[0046] When the pressure rise rate is less than 0.13pa / min, and the vacuum degree is less than 4pa, the electric melting starts. In the initial stage, a stepped power increase mode is adopted (frequency is 30-50kW / 10min until the rated power melts), and the remaining Ni and C are added during the melting process. The whole melting process takes about 120-150min.

[0047] Step 2, a refining process:

[0048] After the bottom material is melted, the temperature is controlled at 1550±10°C, and the low-temperature refining stage is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com