Antistripping composite aluminum veneer

A composite aluminum, anti-stripping technology, applied to building components, cladding/lining, walls, etc., can solve the problems of poor anti-stripping performance of composite aluminum veneers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

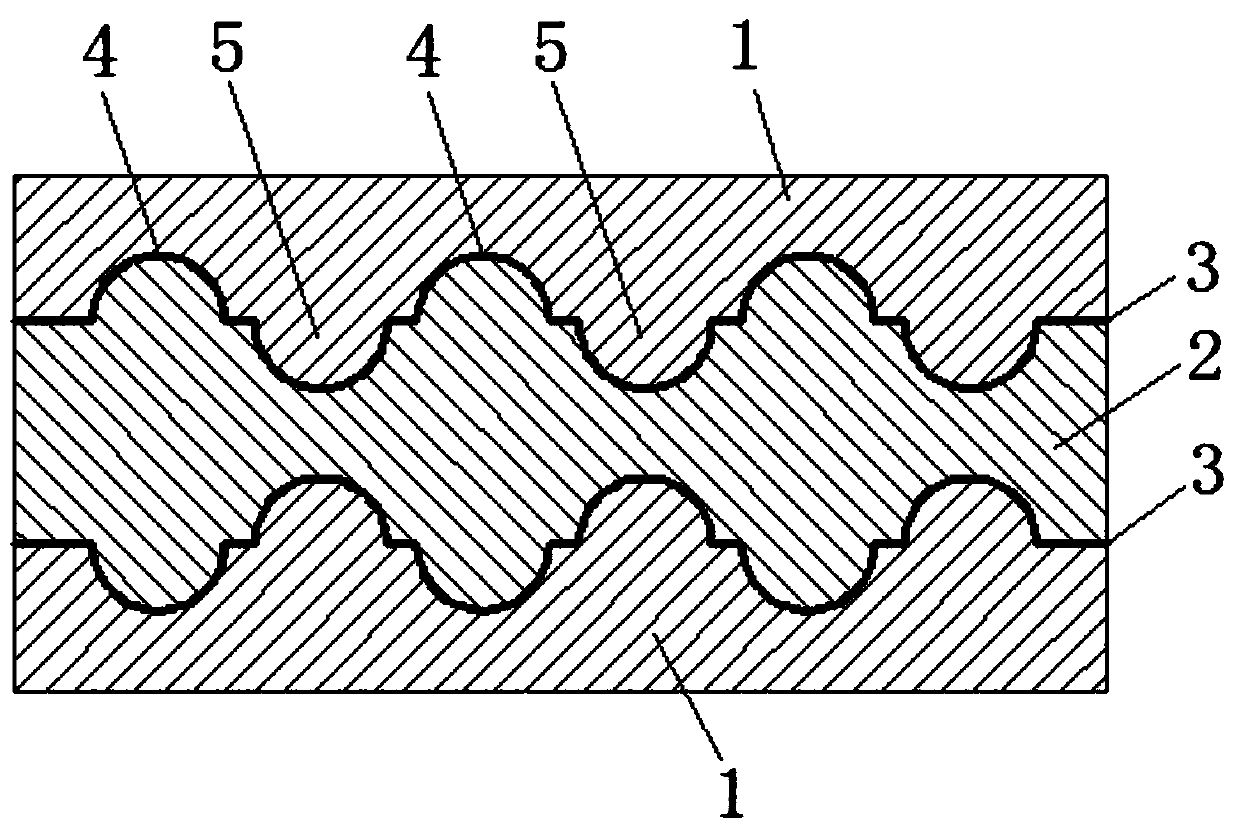

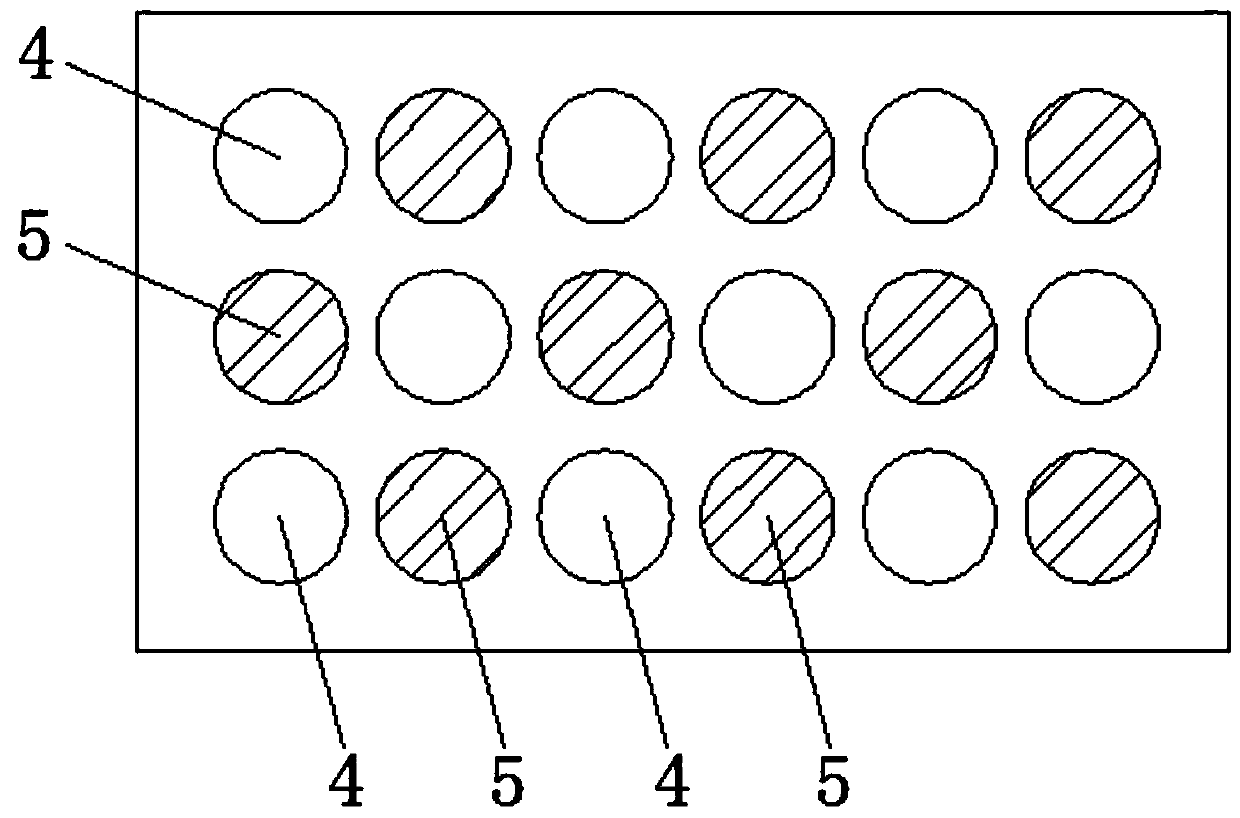

[0020] Such as Figure 1-3 As shown, an anti-peeling composite aluminum veneer includes two aluminum plates 1 and a filling core layer 2 sandwiched between the two aluminum plates 1, and an adhesive layer 3 is provided between the filling core layer 2 and the aluminum plate 1; usually The aluminum plate 1 is made of aluminum or aluminum alloy, the filling core layer 2 is made of plastic material such as polyurethane or polyethylene, and the adhesive layer 3 is used to tightly bond the filling core layer 2 to the aluminum plate 1 .

[0021] Several grooves 4 and / or protrusions 5 are provided on the inner wall of the aluminum plate 1, and the surfaces of the grooves 4 and / or protrusions 5 are spherical. On the one hand, the function of the groove 4 and the protrusion 5 is to increase the contact area between the filling core layer 2 and the aluminum plate 1, that is, to increase the area of the adhesive layer 3, thereby improving the adhesion and increasing the peel resistance...

Embodiment 2

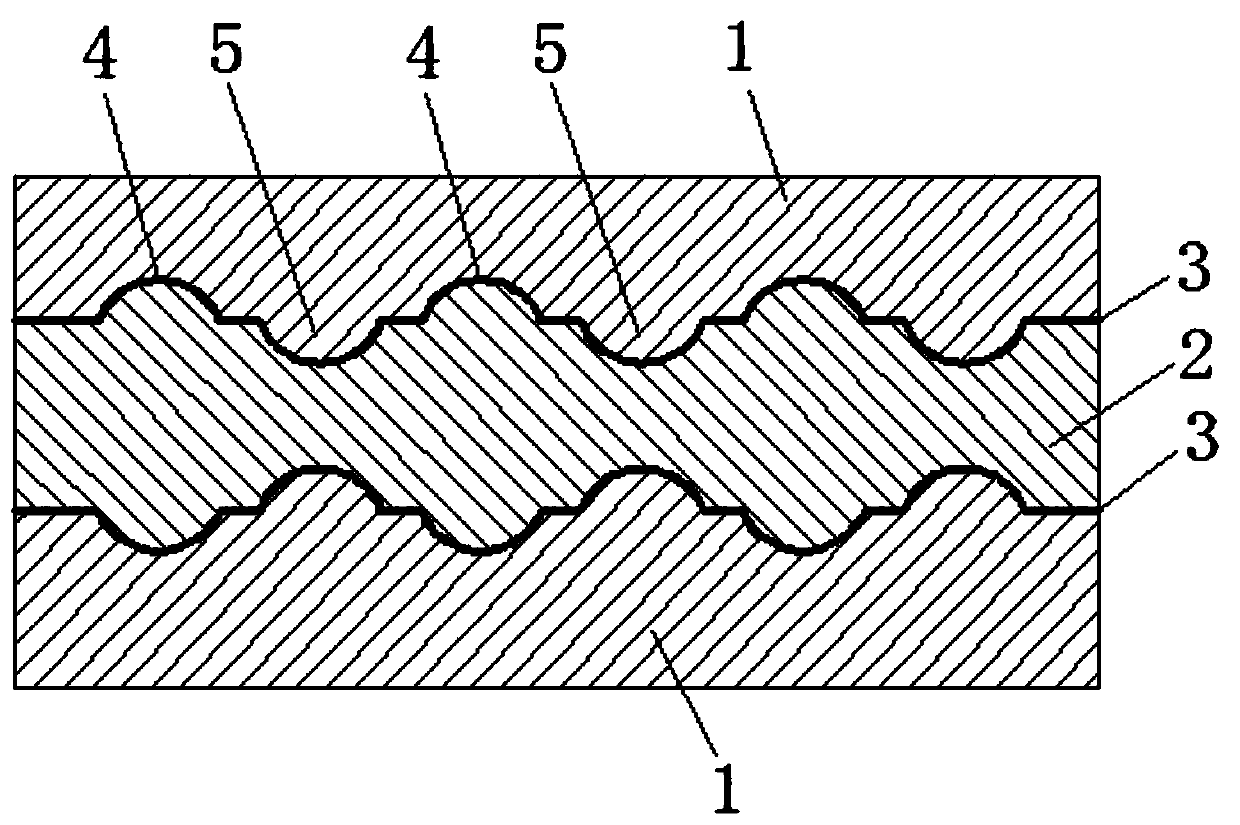

[0026] It differs from Embodiment 1 in that: in this embodiment, the radius of the bottom surface formed on the inner wall of the aluminum plate 1 by the groove 4 and the protrusion 5 is greater than the spherical radius of the surface of the groove 4 and the protrusion 5, such as Figure 4 shown. Such setting makes it difficult for the filling core layer 2 filled in the groove 4 to be detached from the aluminum plate 1 , and also makes it difficult for the protrusion 5 to detach from the filling core layer 2 , so as to achieve higher peeling resistance and structural strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com