Energy-saving aluminum alloy fire window

A technology of aluminum alloy and fireproof windows, which is applied in fireproof doors, windows/doors, fire rescue, etc., can solve the problems of short fire resistance time and difficult support of fireproof windows, and achieve the goal of containing fire, extinguishing flames, and curbing the spread of fire Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

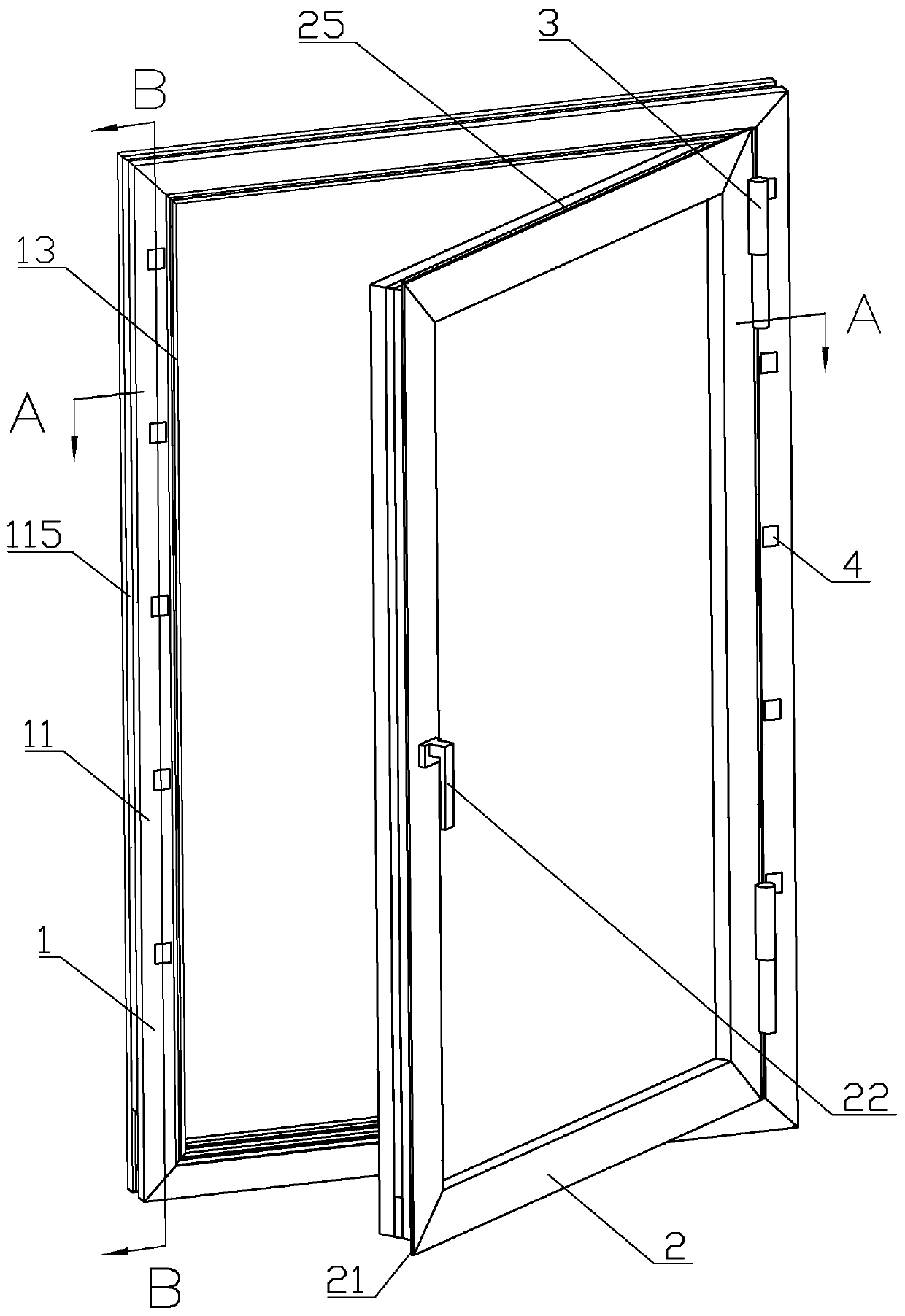

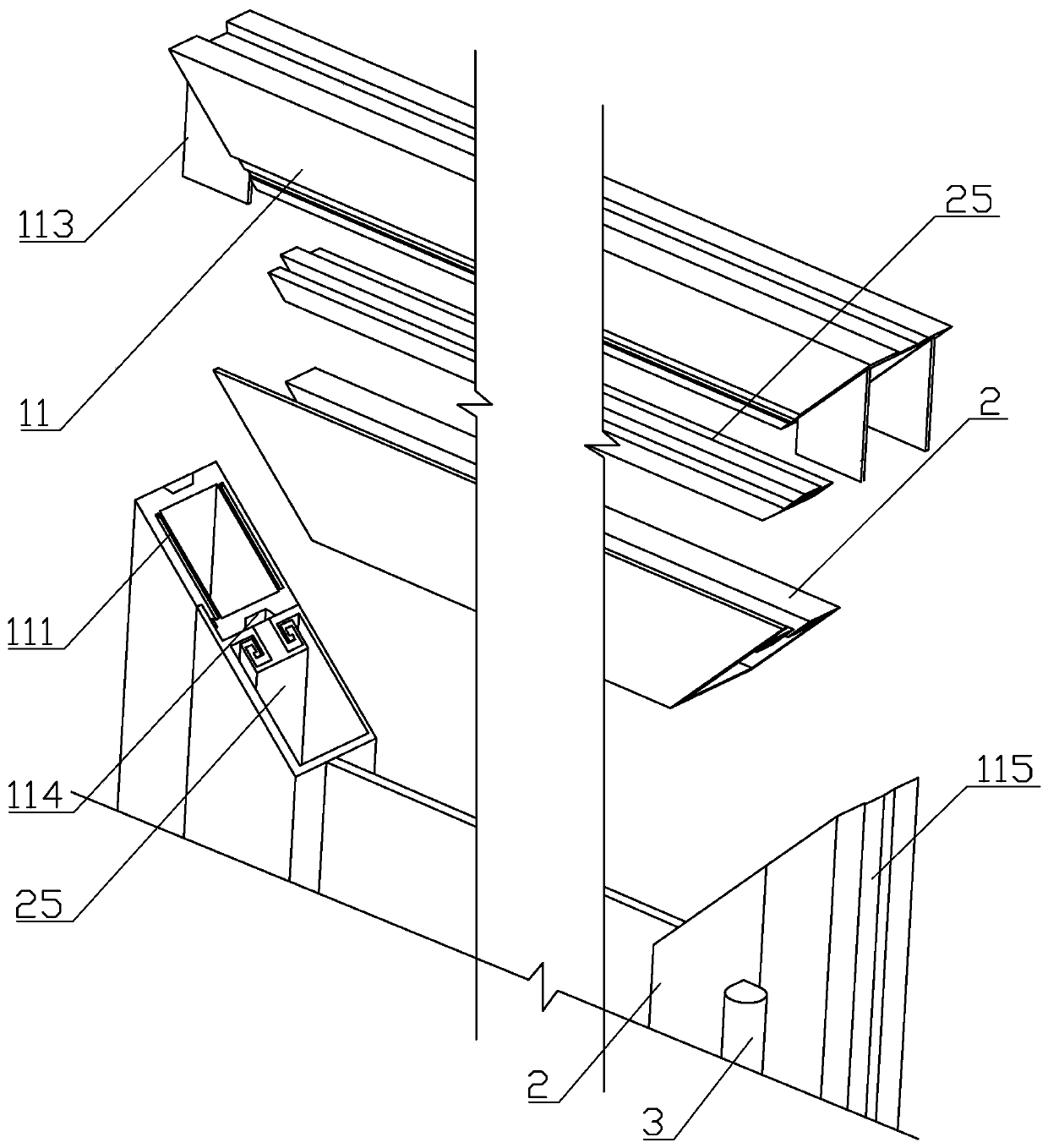

[0038] Embodiment 1: as figure 1As shown, an energy-saving aluminum alloy fireproof window includes a window frame 1 and a window sash 2 . The window frame 1 has a rectangular shape as a whole and is composed of two vertical frames 11 and two horizontal frames 11; the frame 11 is made of aluminum alloy and has good fire resistance. The window sash 2 is also rectangular and made of aluminum alloy material, and a hinge 3 is provided between the window sash 2 and the window frame 1 to realize hinged connection. A handle 22 is also installed on the window sash 2 so that the user can open and close the window sash.

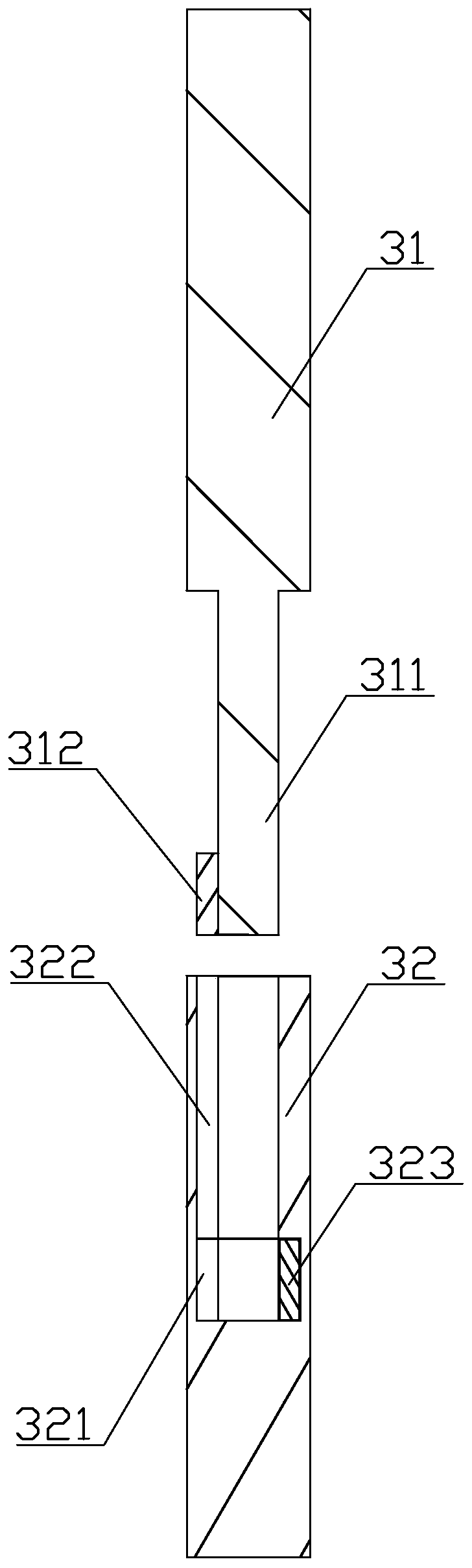

[0039] Such as figure 1 , figure 2 As shown, the hinge 3 includes a chain base 31 and a sleeve 32 . The chain seat 31 is fixed to the side wall of the window sash 2 close to the window frame 1, the sleeve 32 is fixed to a vertical frame 11, and the bottom of the chain seat 31 is fixed with a shaft post 311, which can be inserted into the sleeve 32 and connected to...

Embodiment 2

[0045] Embodiment 2: as figure 1 , Figure 7 As shown, an energy-saving aluminum alloy fireproof window, the difference between this embodiment and Embodiment 1 is that in this embodiment, the fire extinguishing assembly 4 also includes two wax blocks 451 located in the air outlet pipe 45, and the wax blocks 451 are made of paraffin Made, melting point between 45-55 ℃. The superfine dry powder fire extinguishing agent powder is filled between the two wax blocks 451, and the average particle diameter of the ultrafine dry powder fire extinguishing agent powder is about 10 microns, which has good reflammation resistance, dispersibility and electrical insulation. The bottom of the air outlet pipe 45 is also connected with two storage grooves 47 corresponding to the two wax blocks 451 for storing the wax blocks 451 after being heated and melted. The top of the storage tank 47 is funnel-shaped, so that the melted wax block 451 flows in, preventing the wax block 451 from hindering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com