Full-wet circulating water filtration and dust removal system and working method for roadway excavation working face

A technology for excavation working face and circulating water filtration, which is applied in dust prevention, earthwork drilling, safety devices, etc. It can solve the problems of wasting water resources and low dust removal efficiency, achieve secondary utilization, improve dust removal efficiency, and increase contact the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

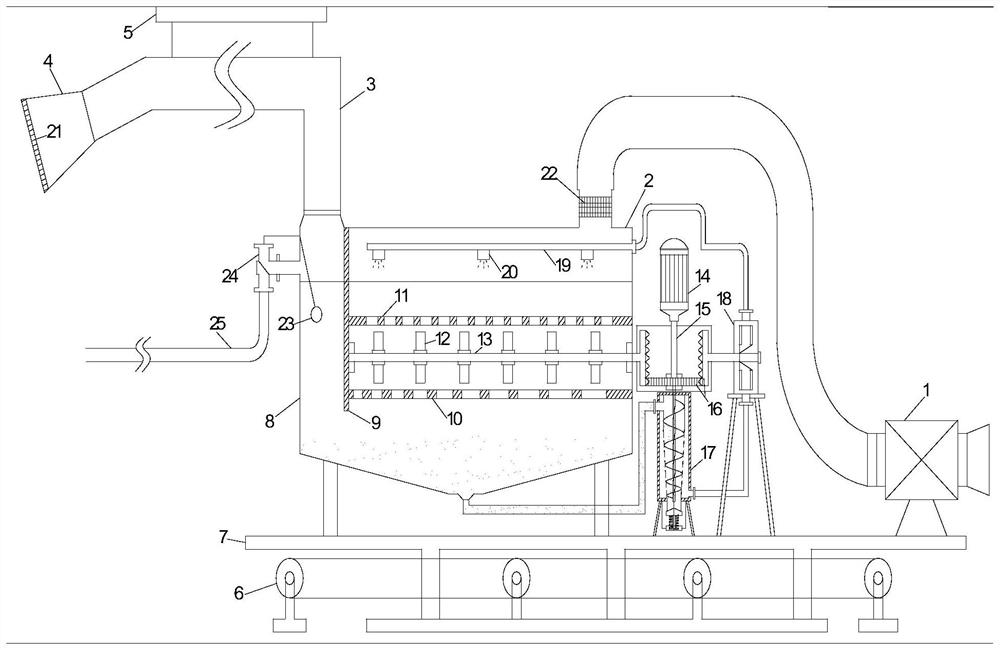

[0049] Such as figure 1 As shown, this embodiment provides a full-wet circulating water filter and dust removal system for roadway excavation working face, including fan 1, spray dust suppression system 2, rigid air cylinder 3, dust collection cover 4, monorail crane 5, belt conveyor 6, The mobile bracket 7 is nested on the top of the belt conveyor 6. The fan 1 and the spray dust suppression system 2 are fixedly installed on the mobile bracket 7. The fan 1 is connected to the air outlet of the spray dust suppression system 2 through the rigid air duct 3. The air inlet of the dust suppression system 2 is connected to the rigid air cylinder 3 and the dust collection cover 4 in turn, and the rigid air cylinder 3 is suspended on the top of the roadway through the monorail crane 5, and the whole system can be coordinated with the excavation process.

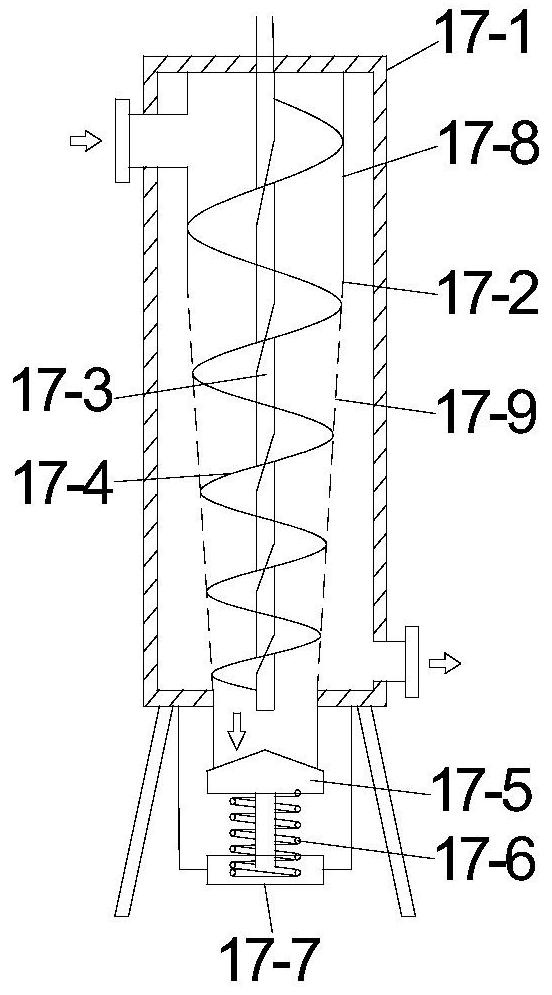

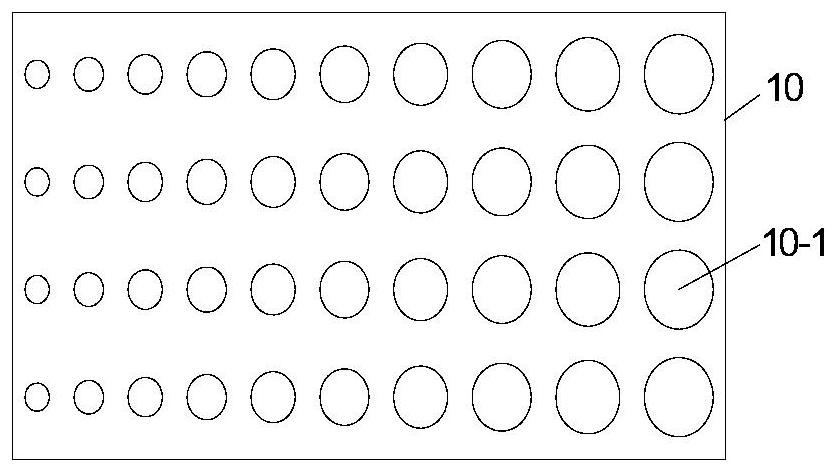

[0050] The spray dust suppression system 2 includes a box body 8, a baffle plate 9, a lower partition plate 10, a stirring unit, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com