Excavating working face patrolling robot and application thereof

A technology for inspection robots and mining working faces, which is applied to instruments, manipulators, motor vehicles, etc., can solve problems such as obstacle-surpassing ability, poor passability, large frictional resistance, and low movement efficiency, and achieve scientific and reasonable structural design. Ground area, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

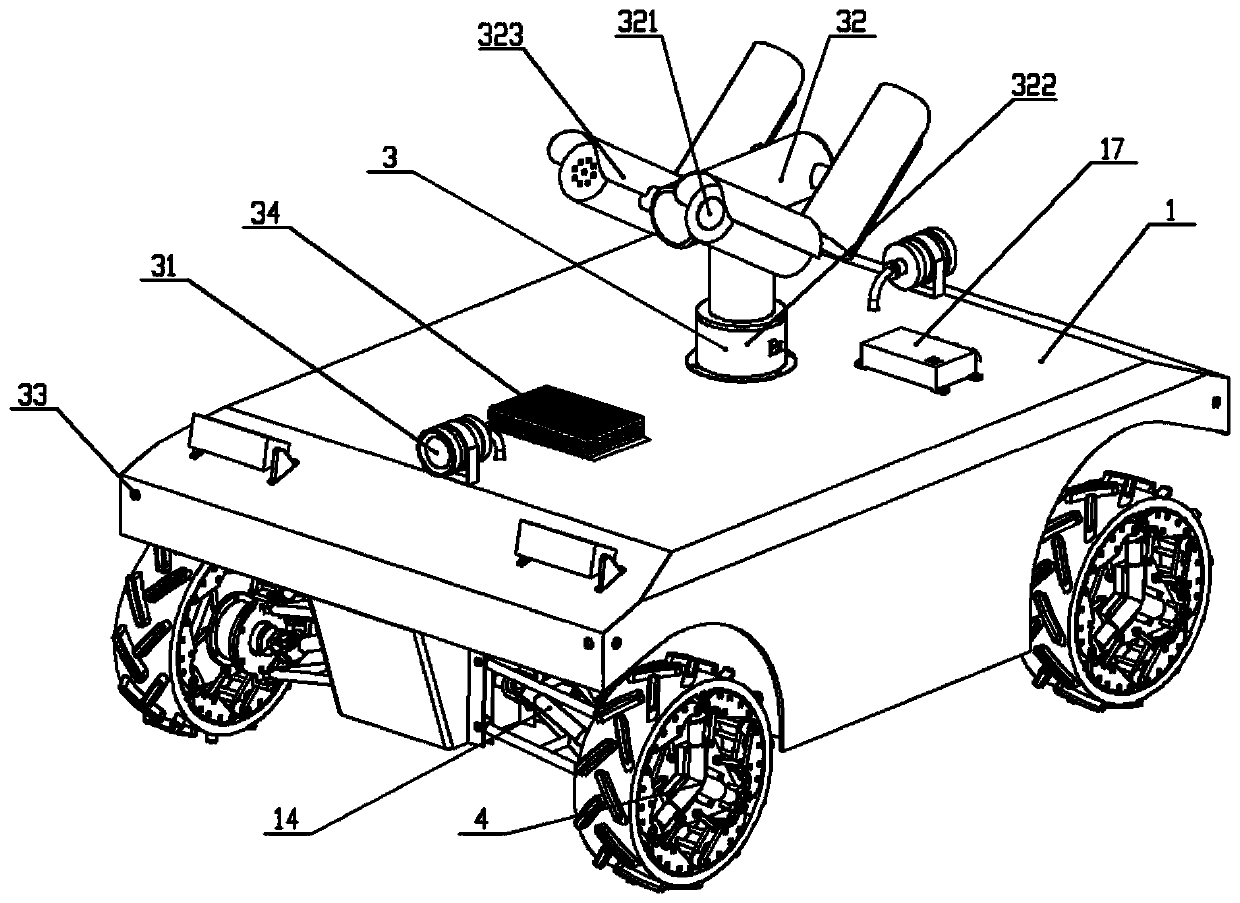

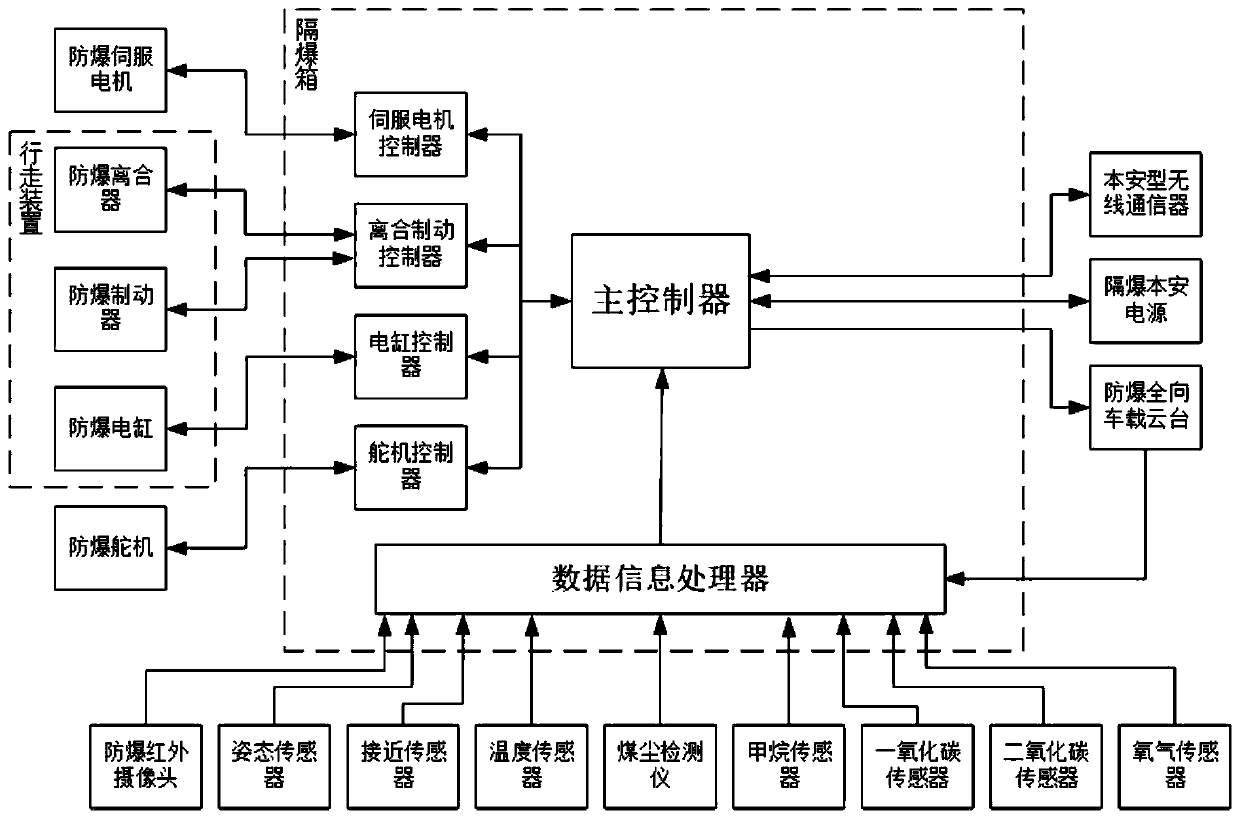

[0055] like Figure 1 to Figure 12 As shown, the present embodiment provides a mining working face inspection robot, the inspection robot mainly includes a body 1, an explosion-proof omnidirectional vehicle-mounted platform 32, a sensor integration module 34, an explosion-proof infrared camera 31, and an intrinsically safe wireless communicator 17 ;

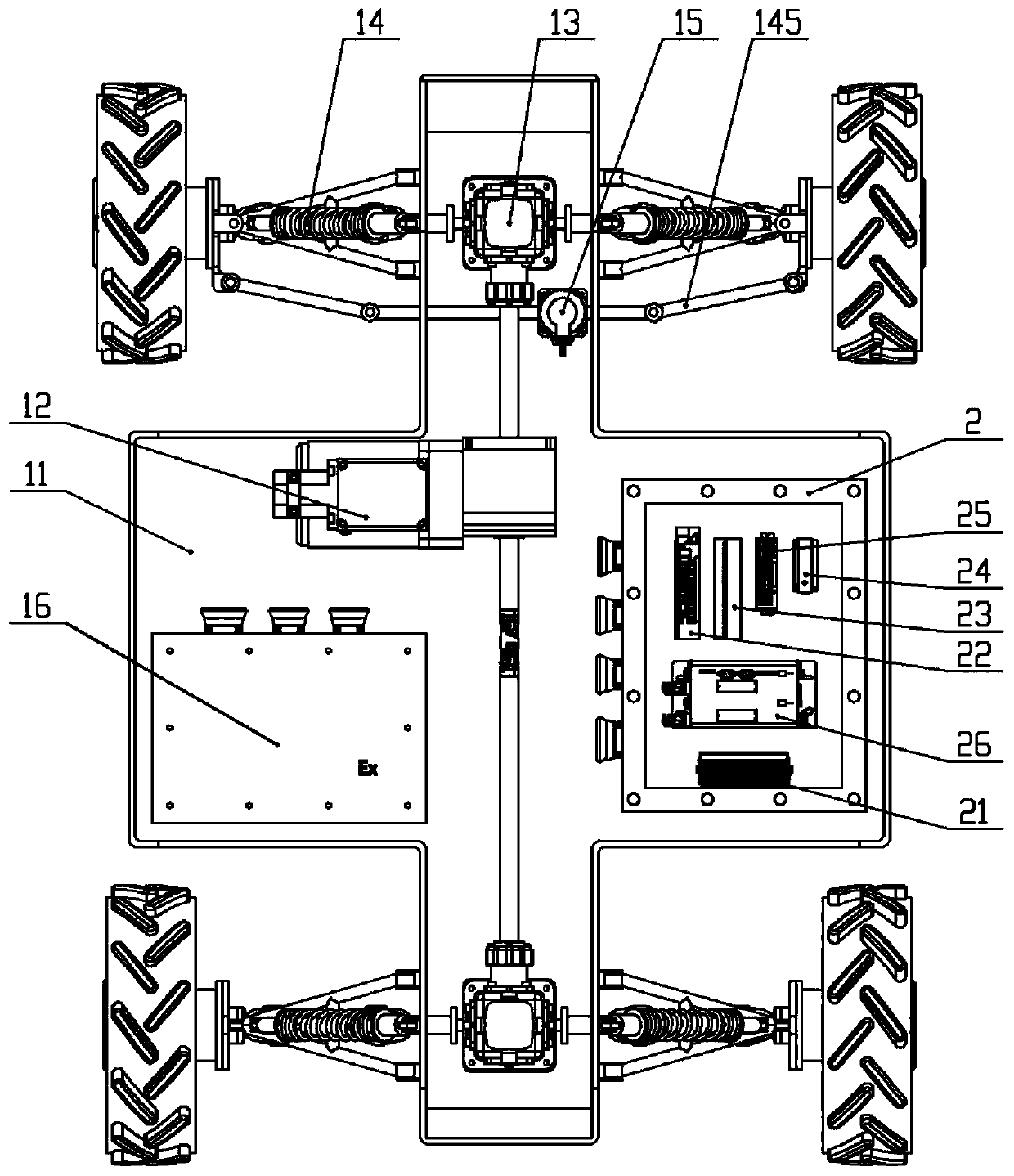

[0056] The body 1 includes a frame 11, an explosion-proof servo motor 12, a transmission device 13, an independent suspension device 14, a running device 4, an explosion-proof steering gear 15, an explosion-proof intrinsically safe power supply 16 and an explosion-proof box 2, wherein the explosion-proof servo motor 12, the explosion-proof The intrinsically safe power supply 16, the explosion-proof steering gear 15, and the explosion-proof box 2 are all installed on the bottom of the frame 11. Four independent suspension devices 14 are symmetrically arranged on the front, rear, left, and right sides of the frame 11. The explosio...

Embodiment 2

[0072] As the working method of the excavation working face inspection robot described in embodiment 1, the specific working process is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com