Thrust calibration system for engine trial stand

A calibration system and aero-engine technology, applied in the direction of engine testing, force/torque/power measuring instrument calibration/testing, machine/structural component testing, etc., can solve the problems of high cost and low cost, and achieve system pressure High efficiency, low power consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

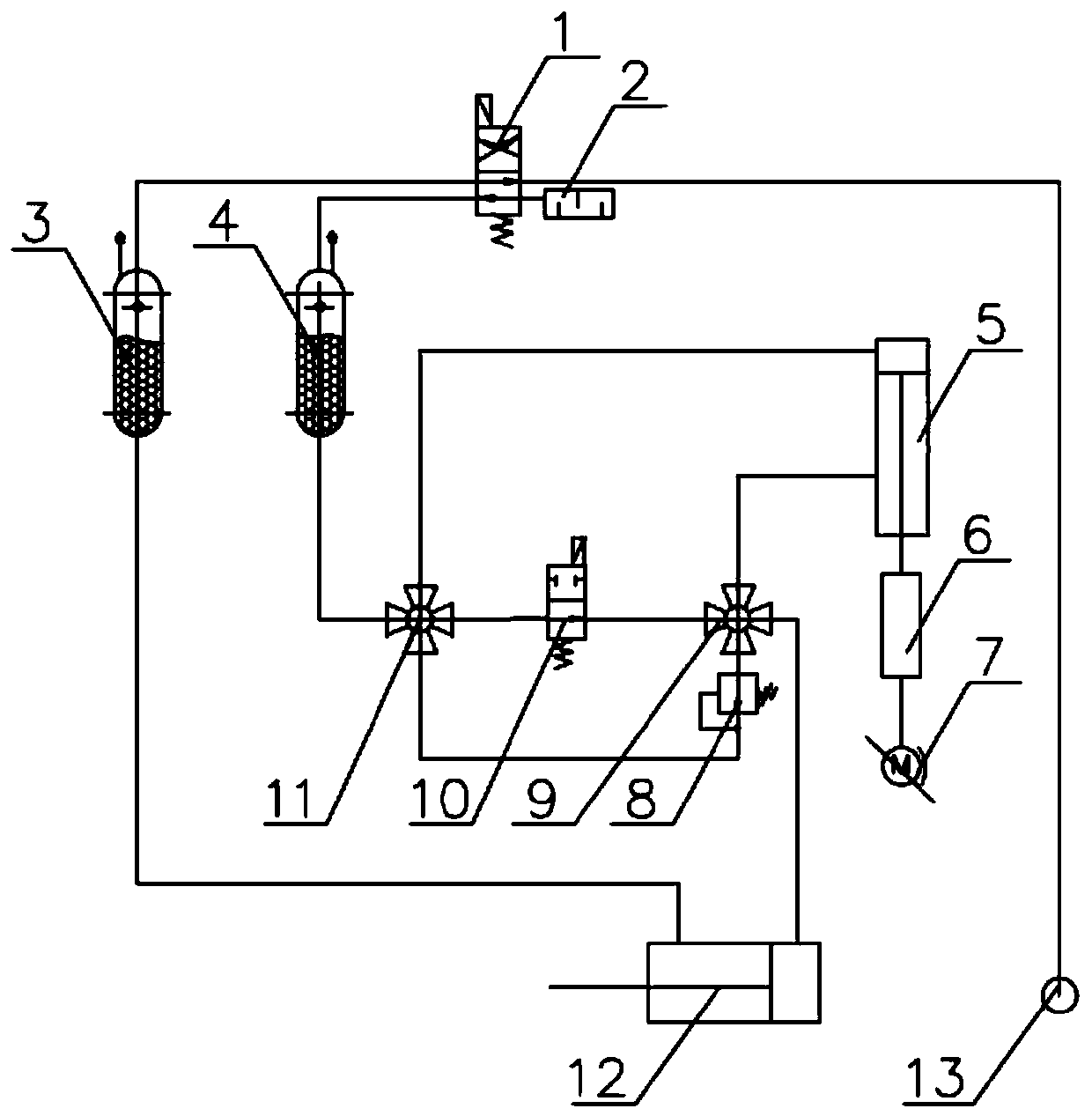

[0042] Embodiment 1, see attached figure 1 , specifically a thrust calibration system for an aero-engine test bench, including a reciprocating drive device, a first four-way, a second four-way, a reversing valve, a loading cylinder, a pressurized cylinder, an overflow valve, an on-off valve, and an air filter , the first surge tank and the second surge tank;

[0043] The overflow valve is set with a threshold value. When the oil pressure in the rod cavity of the booster cylinder exceeds the threshold value, the overflow valve connects the rod cavity of the booster cylinder with the first four-way port; realizing the pressure relief of the rod cavity of the booster cylinder;

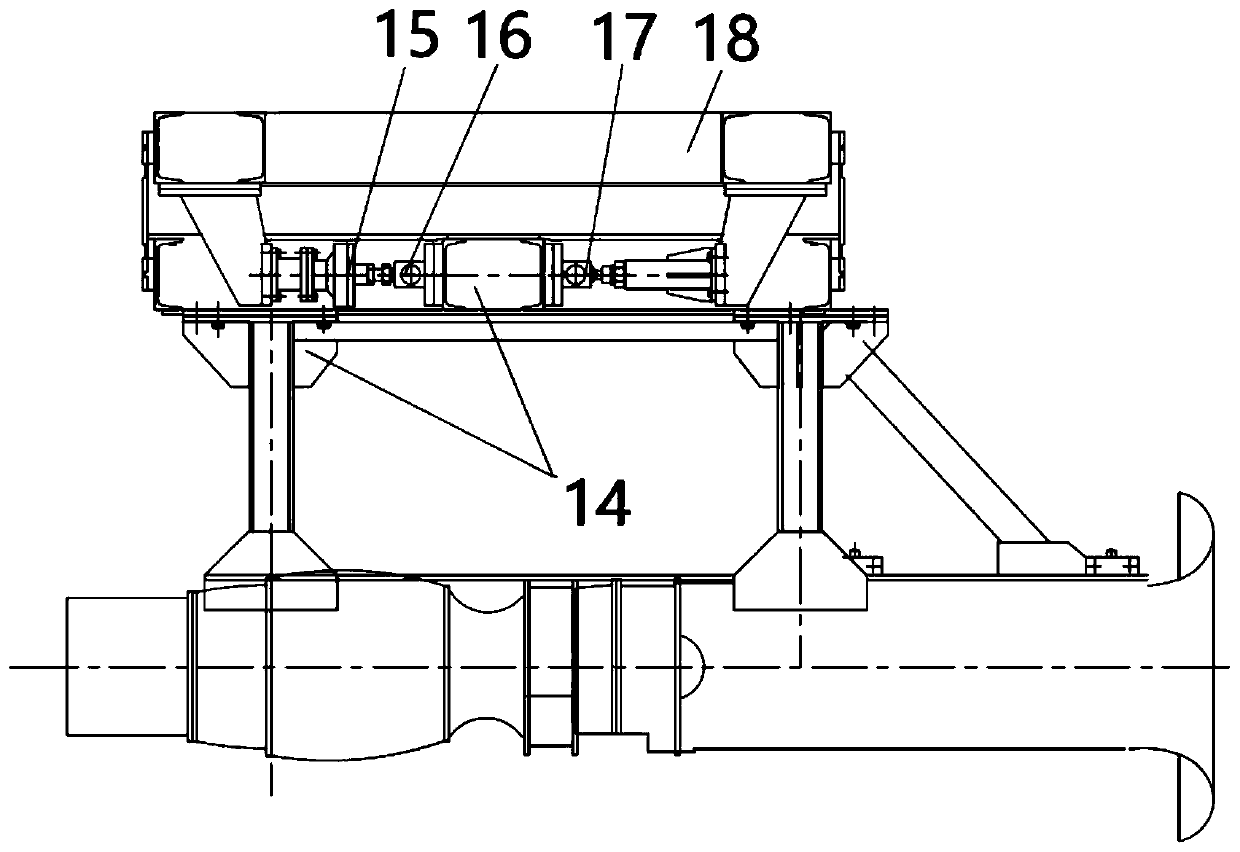

[0044] The test bench includes a moving frame and a fixed frame;

[0045] The cylinder block of the loading cylinder is fixed on one of the movable frame and the fixed frame, and the piston rod of the loaded oil cylinder applies thrust to the other of the movable frame and the fixed frame, and the thrust...

Embodiment 2

[0054] Embodiment 2, see attached figure 1 , specifically a thrust calibration system for an aero-engine test bench, including a reciprocating drive device, a first four-way, a second four-way, a reversing valve, a loading cylinder, a pressurized cylinder, an overflow valve, an on-off valve, and an air filter , the first surge tank and the second surge tank;

[0055] The overflow valve is set with a threshold value. When the oil pressure in the rod cavity of the booster cylinder exceeds the threshold value, the overflow valve connects the rod cavity of the booster cylinder with the first four-way port; realizing the pressure relief of the rod cavity of the booster cylinder;

[0056] The test bench includes a moving frame and a fixed frame;

[0057] The cylinder block of the loading cylinder is fixed on one of the movable frame and the fixed frame, and the piston rod of the loaded oil cylinder applies thrust to the other of the movable frame and the fixed frame, and the thrust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com