Quick detection method for tobacco flavor preparation accuracy

A technology of tobacco flavor and inspection method, which is applied in the analysis of materials, material analysis by optical means, and analysis by chemical reaction of materials, etc. The effect of being easy to carry and saving the cost of material and liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

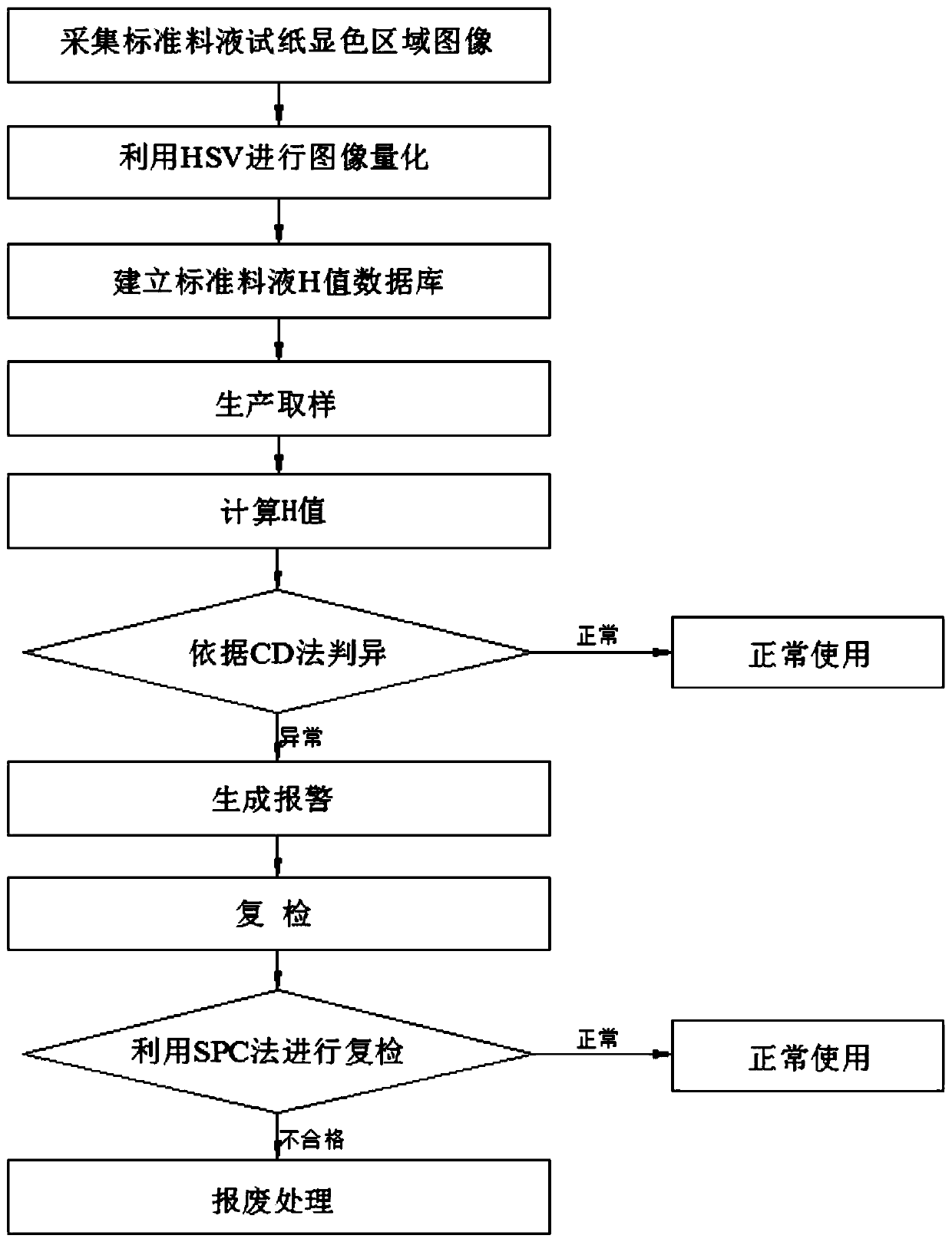

[0040] refer to figure 1 , a kind of rapid testing method for the preparation accuracy of flavorings for tobacco, comprising the following steps:

[0041] Step 1, collect the image of the color area of the standard liquid test paper

[0042] Based on the production formula, the fragrance monomers are weighed and prepared according to the formula ratio requirements. The weighing accuracy is two decimal places when preparing, and the prepared material solution is fully stirred (60min) and heated to 60°C. Dip the material liquid, put it on the pH test paper, and use the shooting equipment to collect the image of the color area within 3s;

[0043] Step 2, use HSV for image quantization

[0044] Quantify the hue H, saturation S, and lightness V of the collected color images, exclude the S value and V value affected by the shooting equipment and the environment, take the hue H value to establish a standard material-liquid comparison library, and calculate each According to the ...

Embodiment 2

[0054] According to Step 3 of Example 1, the H value database of the standard feed liquid was established.

[0055] The results are shown in Table 1:

[0056] Grade 1 Grade 2 Grade 3 Grade 4 Grade 5 Grade 6 Grade 7 Grade 8 Grade 9 standard median 30.23 28.38 34.22 31.64 38.37 24.68 35.29 30.95 29.06 Tolerance ±0.01 ±0.01 ±0.04 ±0.01 ±0.02 ±0.05 ±0.01 ±0.01 ±0.01

Embodiment 3

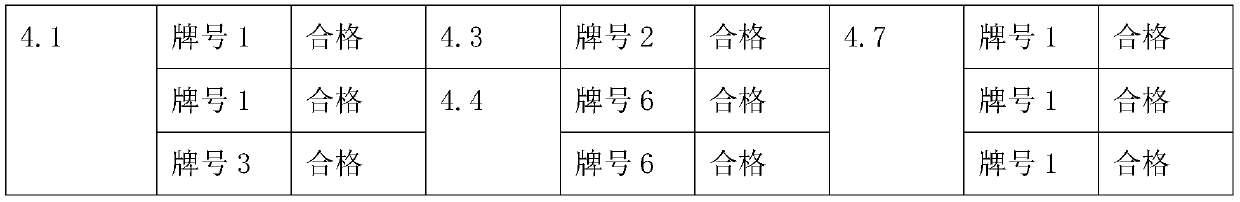

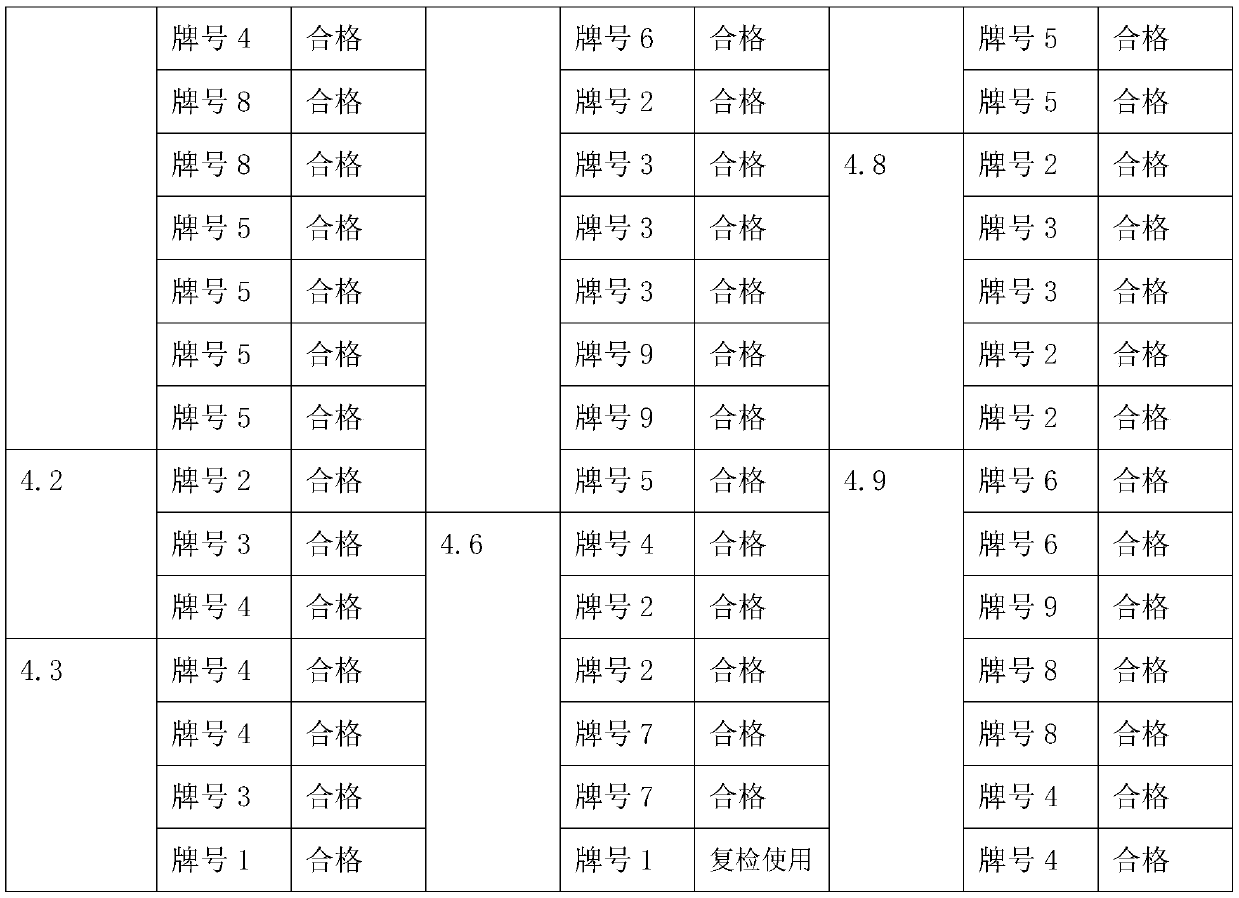

[0058] According to Example 1, the rapid inspection of the preparation accuracy of tobacco flavors was carried out, and the results of the rapid inspection from April 1, 2019 to April 9, 2019 were counted.

[0059] The results are shown in Table 2:

[0060]

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com