Robot push rod driving combined cable capable of automatically compensating for bending

A technology of automatic compensation and combination of cables, applied in the direction of bendable cables, bendable conductors, insulated cables, etc., can solve the problems of accelerated core wear, shortened cable service life, core wires pierced through insulators, etc., to reduce wear and tear The effect of speed, extended service life, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

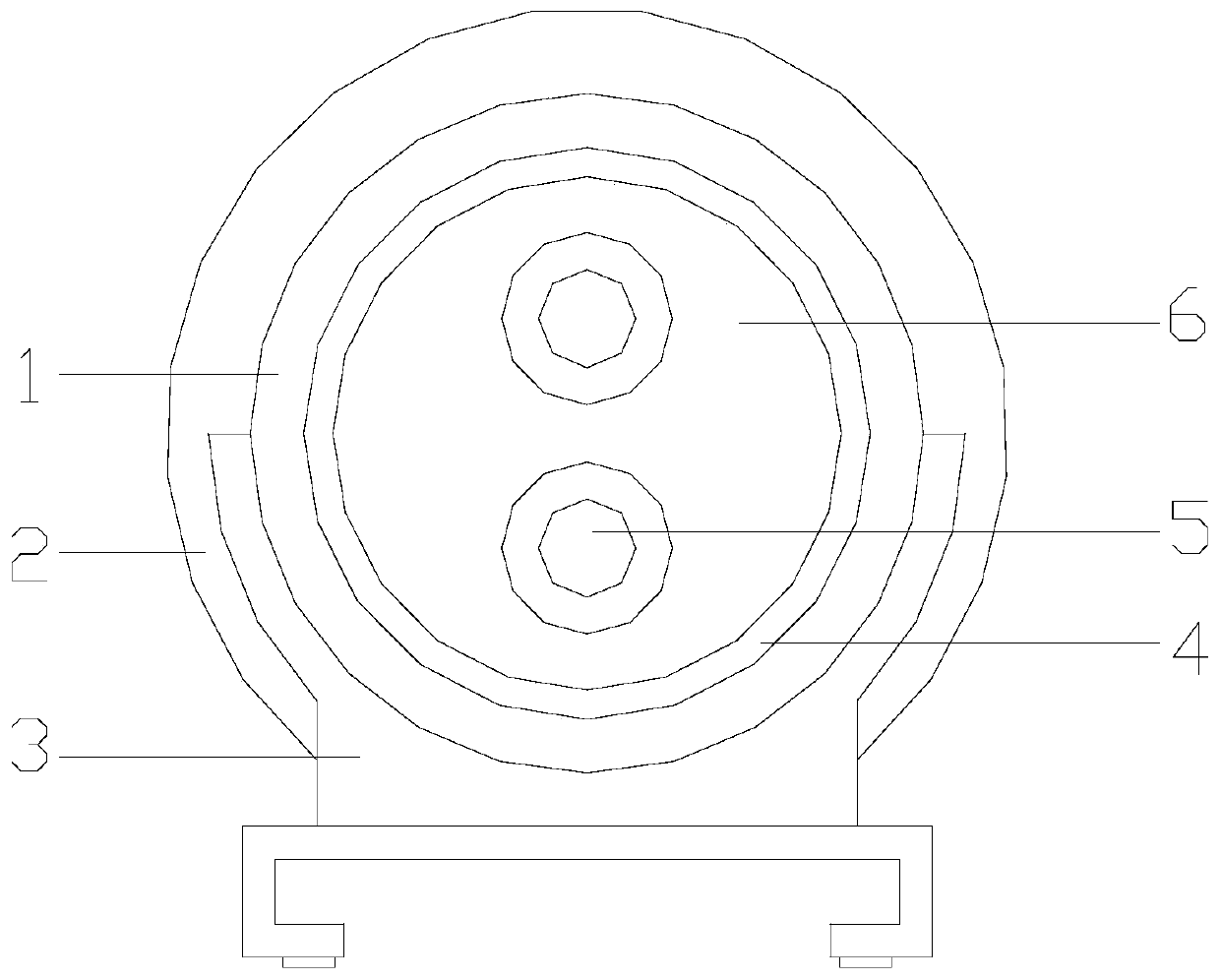

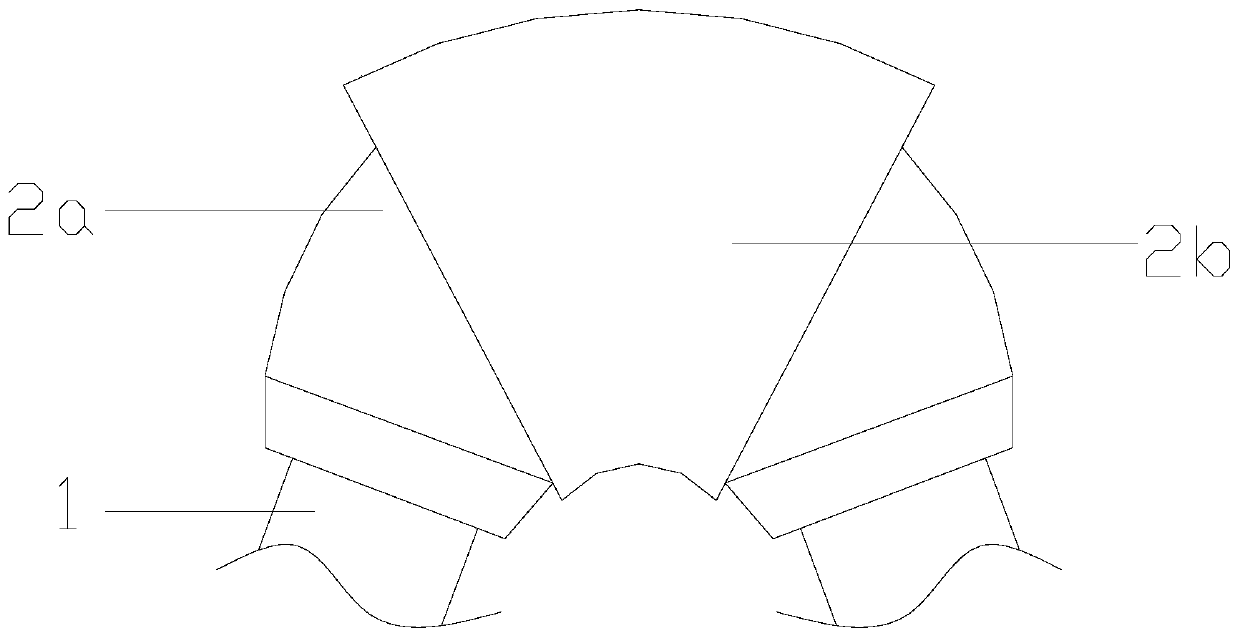

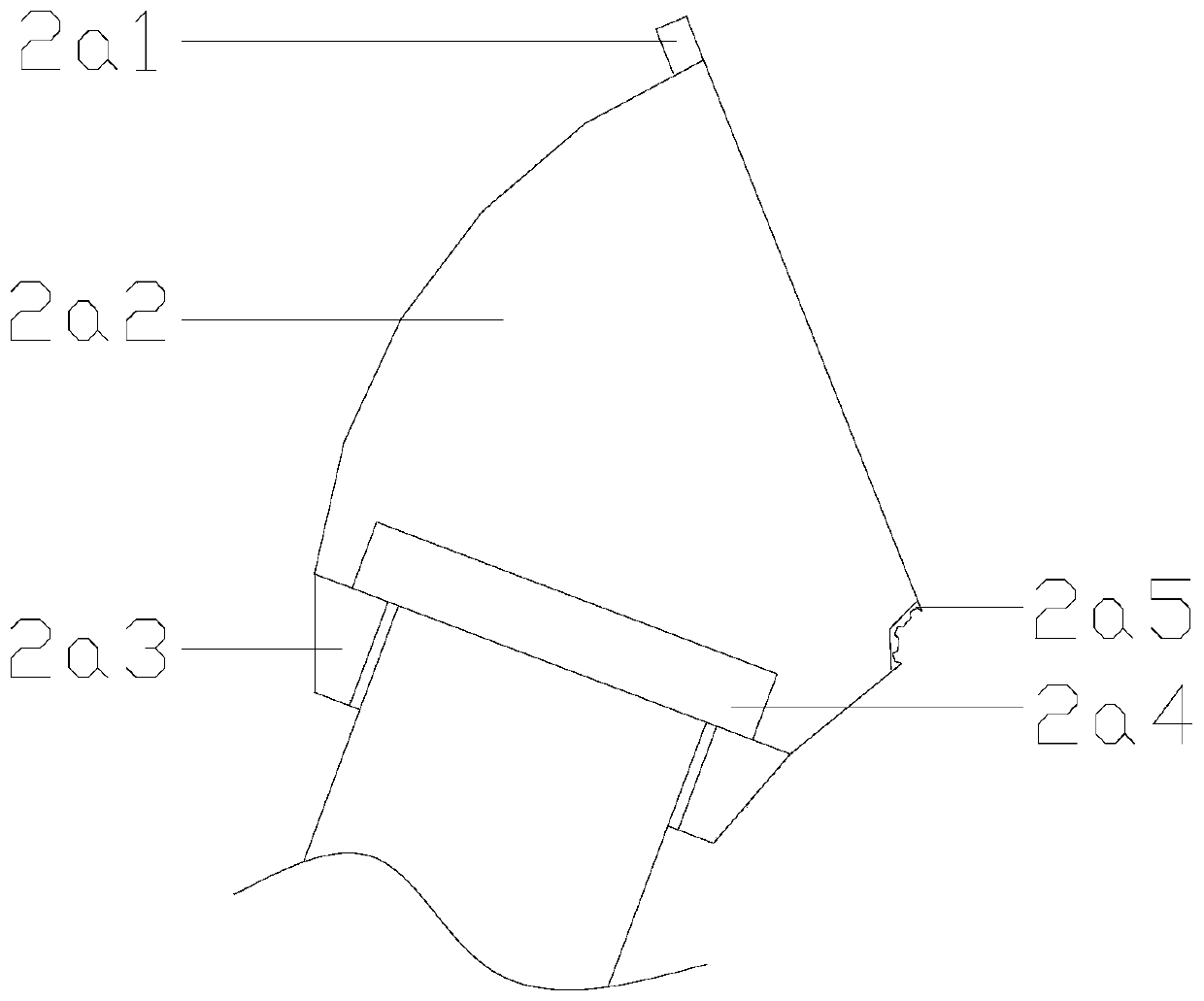

[0028] see Figure 1-Figure 2 , the present invention provides a robot push rod driven combination cable with automatic bending compensation, the structure of which includes an outer sheath 1, a bending compensation structure 2, a cable fixing frame 3, a copper wire braided shielding layer 4, a signal transmission core 5, and a filling layer 6 , the bottom of the cable fixing frame 3 and the robot push rod are fixed together by bolts, the bottom surface of the outer sheath 1 and the upper surface of the cable fixing frame 3 are bonded together, and the copper wire braided shielding layer 4 is located on the outer sheath Inside the layer 1 and concentric with the outer sheath layer 1, the signal transmission core 5 is provided with two and installed inside the copper wire braided shielding layer 4 sequentially from top to bottom, and the filling layer 6 is nested in the copper wire Inside the braided shielding layer 4, the bending compensation structure 2 is fastened with the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com