Method for quickly calibrating cutting air pressure

A high-pressure and fast technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of affecting processing efficiency, waste gas, and time-consuming, so as to improve processing efficiency, reduce the time of pressure calibration, and save cutting. gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below according to the accompanying drawings.

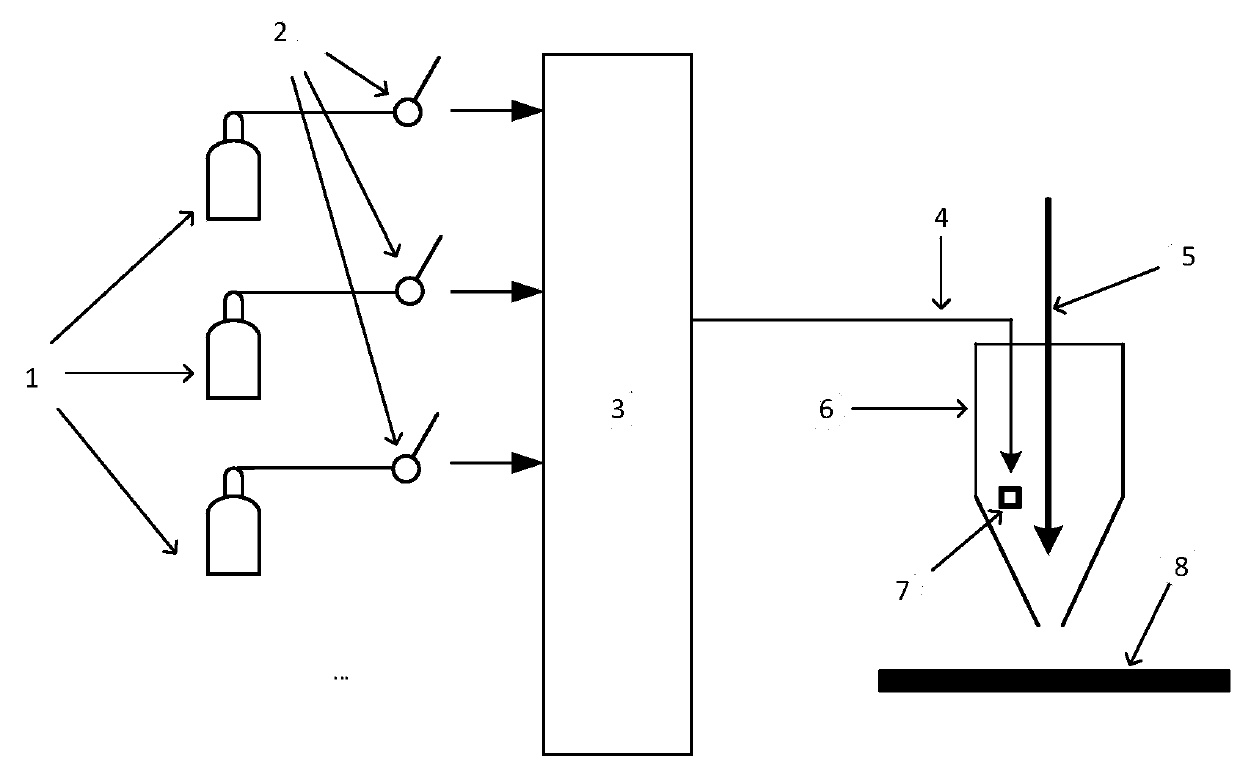

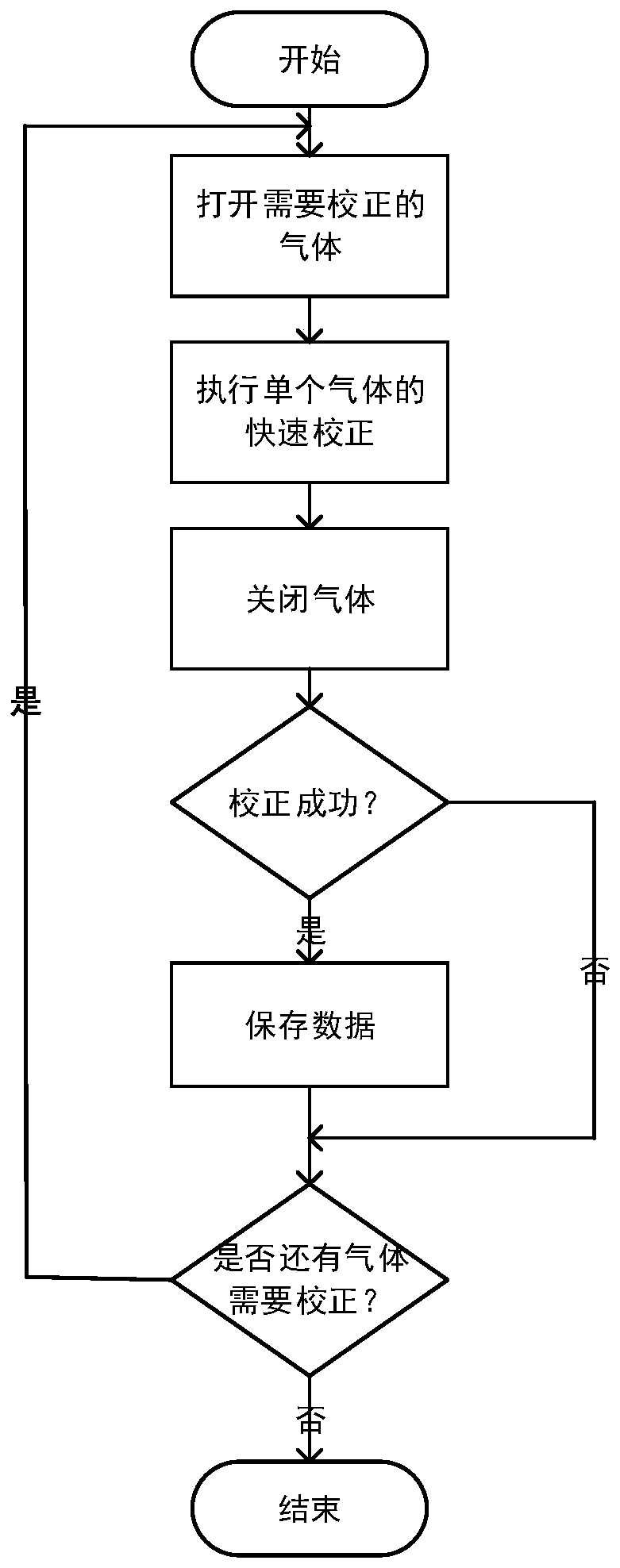

[0028] Such as figure 1 As shown, the gas 1 that needs to be corrected is opened by the corresponding switch 2 and enters the electropneumatic pressure reducing valve 3, and the output gas 4 enters the laser cutting head 6 to assist the laser 5 to process the material 8; the air pressure value in the processing process is determined by the air pressure The sensor 7 is sampled and acquired, and it is characterized in that: the method includes a single-channel gas correction method, a one-time correction method for all gas pressures,

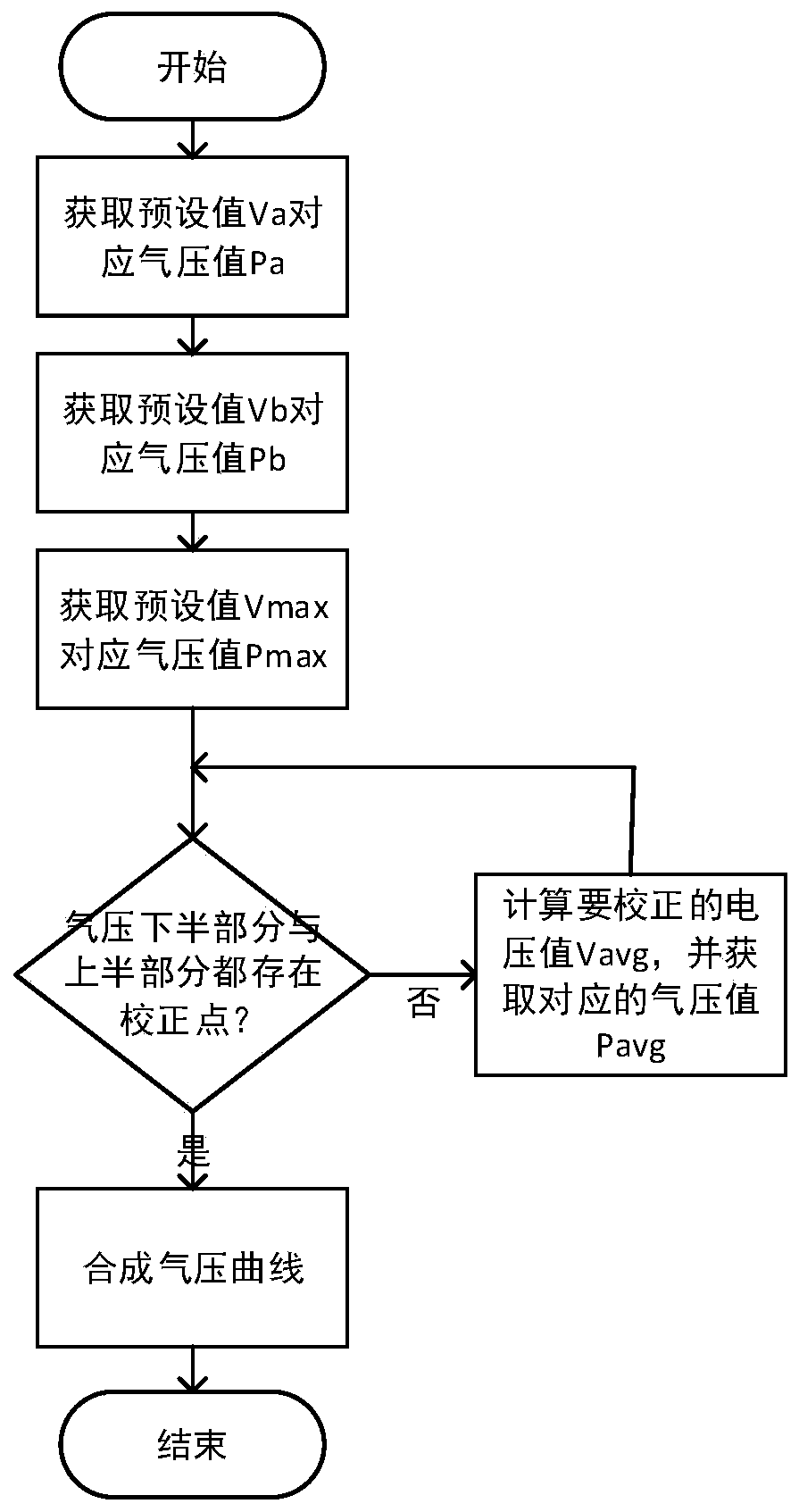

[0029] Such as figure 2 As shown, the single-channel gas calibration method is as follows:

[0030] (11) Turn on the switch corresponding to the gas that needs to be calibrated, set the electropneumatic pressure reducing valve at the voltage Va, and obtain the pressure value Pa of the pressure sensor in the stable state, record A (Va, Pa);

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com