Dust Suppression System for Construction Sites

A technology for building construction and construction sites, which is applied in sustainable buildings, separation methods, liquid fuel engines, etc., and can solve the problems of small dust reduction area and poor dust reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

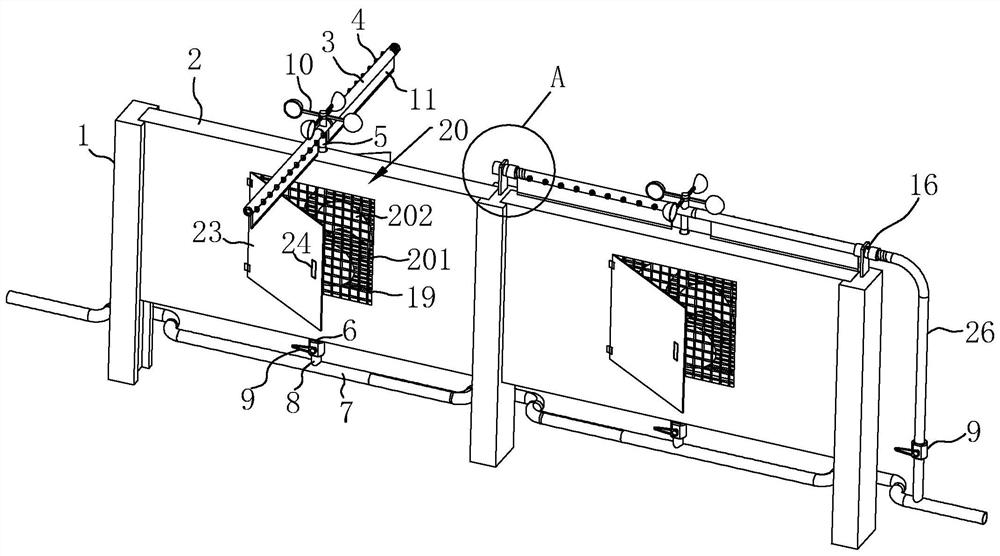

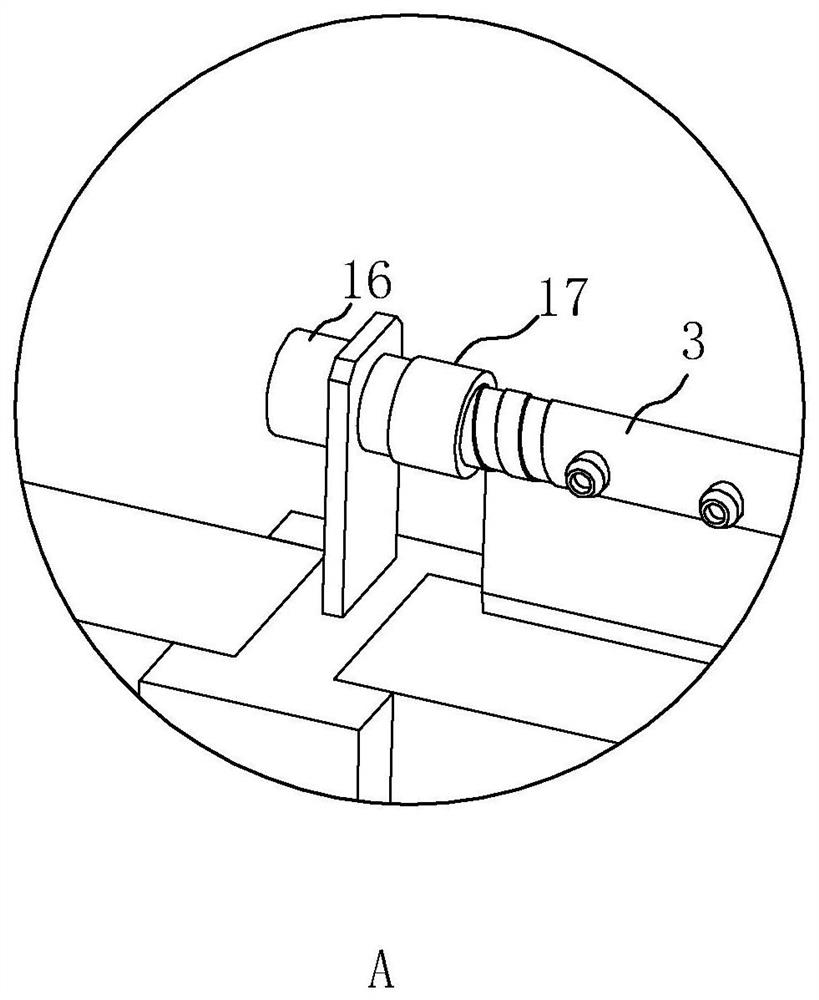

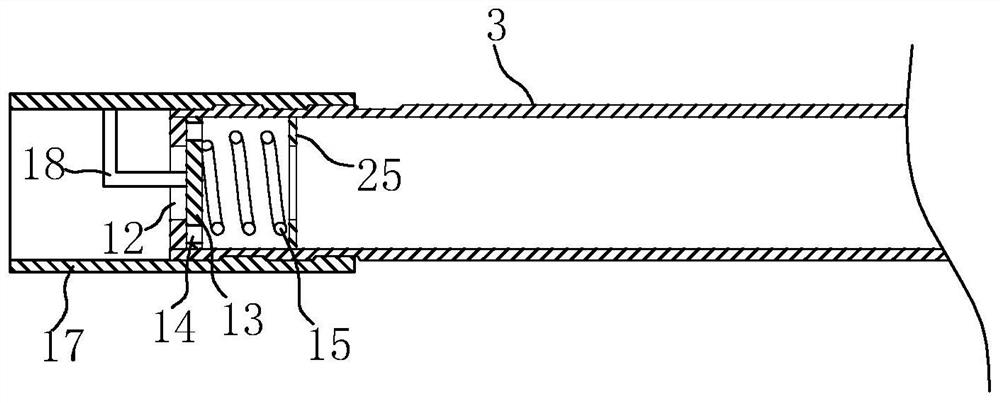

[0039] A construction site dust suppression system, such as figure 1As shown, it includes an enclosure, which includes a column 1 and a panel 2, and the panels 2 are respectively located between adjacent columns 1 and fixed to form an enclosure, and the top wall of each panel 2 is provided with spray Water pipe 3, on the water spray pipe 3, nozzles 4 for spraying water are arranged at intervals along its length direction, and a connecting pipe 5 communicating with it extends downward in the middle of the water spray pipe 3, and one end of the connecting pipe 5 penetrates into the spout The board 2 is connected with it in rotation; at the same time, a water pipe 6 for water supply is penetrated at the bottom of the panel 2, wherein the connecting pipe 5 is rotatably connected to the top of the water pipe 6 and the two communicate with each other, and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com