Polyamide film for flexible packaging of lithium battery and preparation process thereof

A polyamide film and flexible packaging technology, applied in the field of polyamide film and its preparation technology, can solve problems such as difficulty in meeting, and achieve the effects of good dimensional stability, low bow effect and good film surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

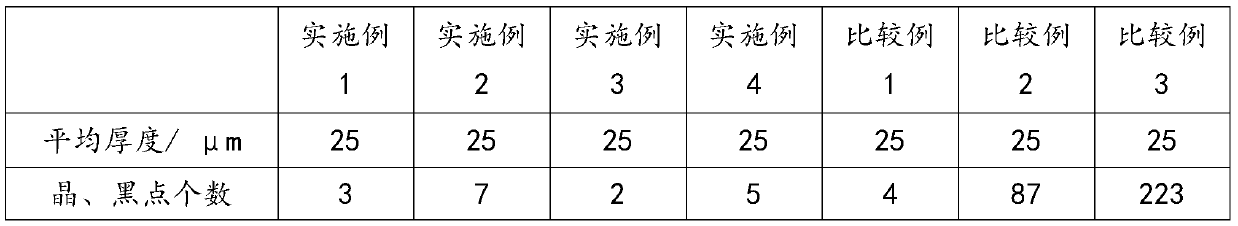

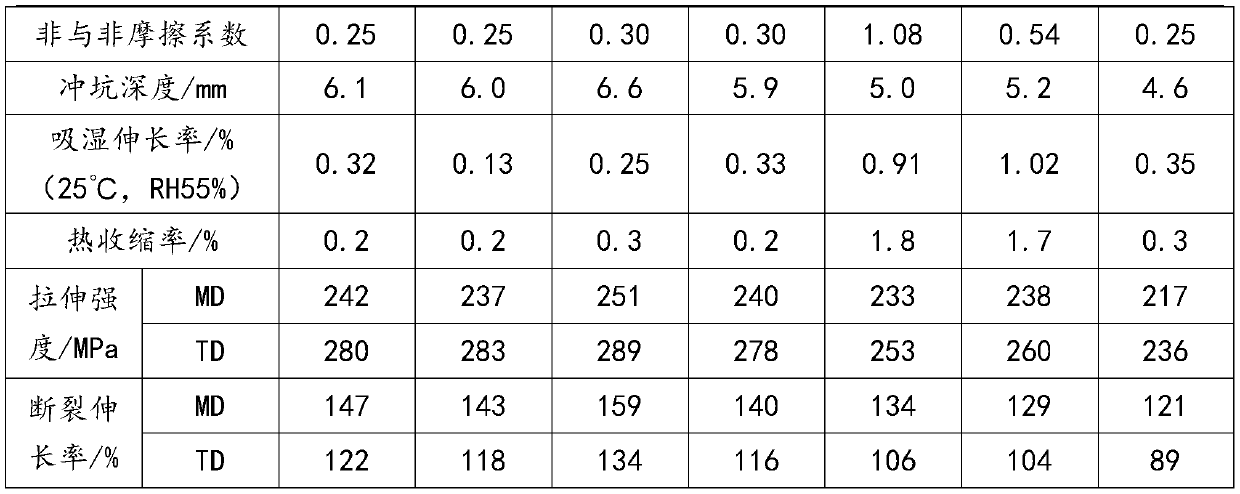

Examples

Embodiment 1

[0038] A kind of polyamide film used for flexible packaging of lithium batteries has a three-layer structure,

[0039] The mass percentage of the upper surface layer 1 component is: functional masterbatch A 4%, nylon 6 96%;

[0040] The mass percentage of the core layer 2 components is: functional masterbatch B 6%, nylon 6 94%;

[0041] The mass percentages of the three components of the lower surface layer are: functional masterbatch C 4%, nylon 6 96%.

[0042] The mass percentage of component A of the functional masterbatch is: soft butyl polyacrylate cross-linked particles 6%, nylon 694%;

[0043] The mass percentage of component B of the functional masterbatch is: nano-magnesium oxide 6%, nylon 6 94%;

[0044] The mass percentage of component C of the functional masterbatch is: soft polyacrylate butyl resin cross-linked particles 6%, silicone wax powder 2%, nylon 6 92%.

[0045] The upper surface layer 1 has a thickness of 1.7 μm.

[0046] The thickness of the core lay...

Embodiment 2

[0049] A kind of polyamide film used for flexible packaging of lithium batteries has a three-layer structure,

[0050] The mass percentage of the upper surface layer 1 component is: functional masterbatch A 6%, nylon 6 94%;

[0051] The mass percentage of the core layer 2 components is: functional masterbatch B 10%, nylon 6 90%;

[0052] The mass percentages of the three components of the lower surface layer are: functional masterbatch C 6%, nylon 6 94%.

[0053] The mass percentage of component A of the functional masterbatch is: soft butyl polyacrylate cross-linked particles 8%, nylon 692%;

[0054] The mass percentage of component B of the functional masterbatch is: nano-magnesium oxide 8%, nylon 6 92%;

[0055] The mass percentage of component C of the functional masterbatch is: 8% soft polyacrylate cross-linked particles, 2% silicone wax powder, and 90% nylon 6.

[0056] The upper surface layer 1 has a thickness of 1.7 μm.

[0057] The thickness of the core layer 2 is 2...

Embodiment 3

[0060] A kind of polyamide film used for flexible packaging of lithium batteries has a three-layer structure,

[0061] The mass percentage of the upper surface layer 1 component is: functional masterbatch A 4%, nylon 6 96%;

[0062] The mass percentage of the core layer 2 components is: functional masterbatch B 6%, nylon 6 79%, nylon 1212 15%;

[0063] The mass percentages of the three components of the lower surface layer are: functional masterbatch C 4%, nylon 6 96%.

[0064] The mass percentage of component A of the functional masterbatch is: soft butyl polyacrylate cross-linked particles 6%, nylon 694%;

[0065] The mass percentage of component B of the functional masterbatch is: nano-magnesium oxide 6%, nylon 6 94%;

[0066] The mass percentage of component C of the functional masterbatch is: soft polyacrylate butyl resin cross-linked particles 6%, silicone wax powder 2%, nylon 6 92%.

[0067] The upper surface layer 1 has a thickness of 1.7 μm.

[0068] The thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com