Production method of petroleum resin

A production method and technology of petroleum resin, applied in the field of continuous operation of petroleum resin production, can solve the problems of restricted production capacity, large fluctuation of product quality, long production cycle, etc., to achieve control of molecular weight and molecular weight distribution, stable and consistent performance indicators, and achieve The effect of large-scale industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0035] Embodiment 2 prepares petroleum resin with C9 fraction as raw material

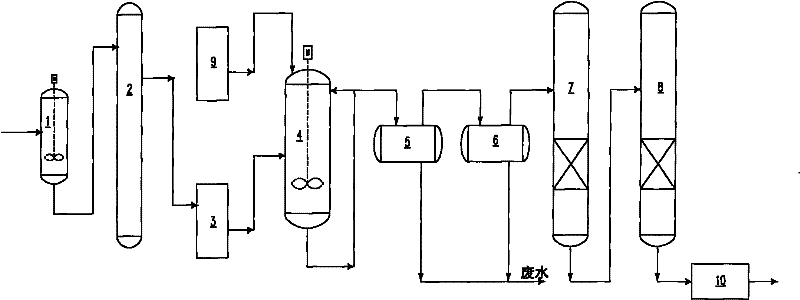

[0036] according to figure 1 The process flow shown prepares petroleum resin.

[0037] 1) Pretreatment: Concentrate the C9 fraction (purchased from Lanzhou Petrochemical) directly in the rectification tower 2, the total content of styrene and indene in the concentrated C9 fraction is 60wt%, and the content of dicyclopentadiene is 1.5% ;

[0038] 2) Polymerization: Through preliminary experiments, it is determined that the weight percent concentration of the catalyst in the polymerization product is 1.8 to 2% as a standard, and the addition amount and reaction progress of the catalyst are controlled;

[0039] Then the C9 fraction after the above pretreatment is mixed with the mixed solvent of normal hexane and hexanaphthene in the raw material premixing tank 3 according to the ratio of 1:1 by weight, and sent into the polymerization reactor 4. 9 Stably and continuously add the catalyst aluminum t...

Embodiment 3

[0044] Embodiment 3 prepares petroleum resin with C5 fraction and C9 fraction as raw material

[0045] according to figure 1 The process flow shown prepares petroleum resin.

[0046] 1) Pretreatment: The pretreatment methods of the C5 fraction and the C9 fraction are the same as those in Examples 1 and 2 respectively. The content of pentadiene in the concentrated C5 fraction is 70 wt%, and the total content of styrene and indene in the concentrated C9 fraction is The content is 80wt%, and the two concentrates are mixed according to the weight ratio of the C5 fraction and the C9 fraction at 3:1;

[0047] 2) Polymerization: Through preliminary experiments, it is determined that the weight percent concentration of the catalyst in the polymerization product is 1 to 1.2% as a standard, and the amount of addition of the catalyst and the progress of the reaction are controlled;

[0048] Mix the above C5 fraction and C9 fraction mixed solution with the mixed solvent of toluene and x...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com