Optical protective film for liquid crystal polarizer

A polarizing plate and protective film technology, applied in the direction of pressure-sensitive film/sheet, film/sheet-like adhesive, paint containing biocide, etc., can solve problems such as complex product structure, achieve simple product structure, reduce surface area The effect of improving the transmittance of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

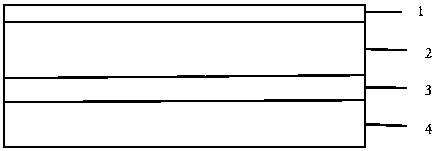

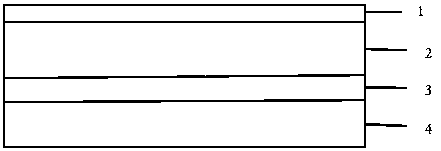

Image

Examples

Embodiment 1

[0033]

[0034]

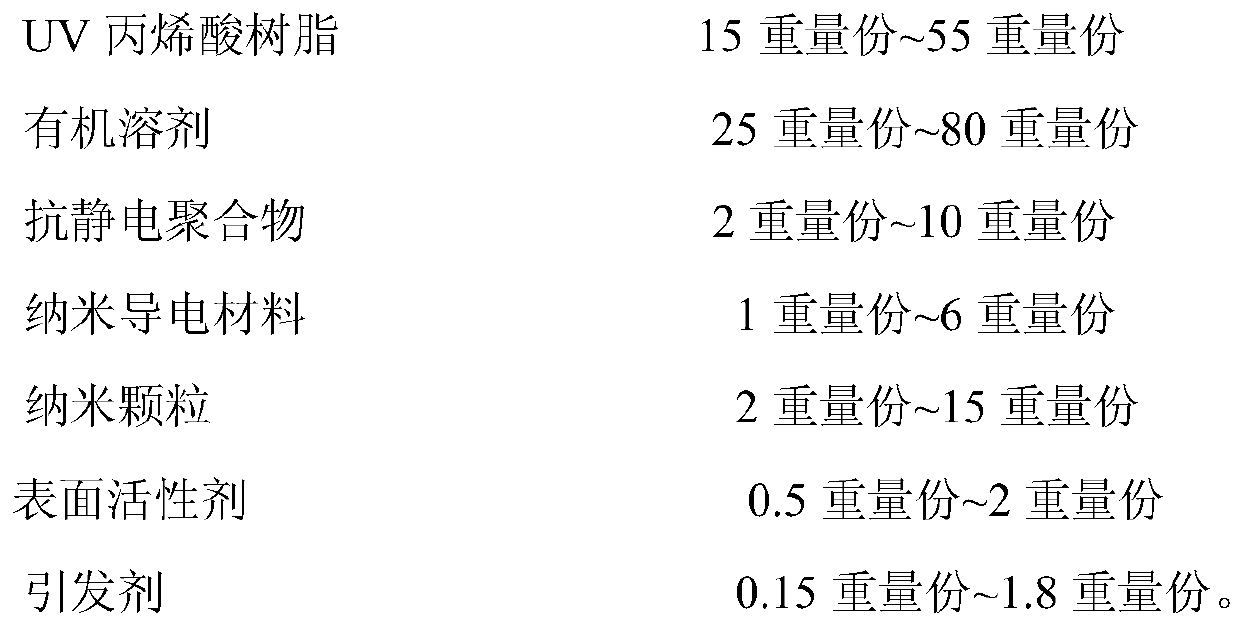

[0035] In the dipentaerythritol pentaerythritol pentaacrylate, hexaacrylate and 10g polyaniline, add the nano-silver wire of 6g (Suzhou cold stone nanometer material science and technology, the average wire diameter is 40nm) and the silica sol of 14g (manufactured by Nissan Chemical, the average particle diameter is 0.01 μm), and added 2g of polyester-modified hydroxyl-functional polydimethylsiloxane (manufactured by BYK, trade name: BYK370) and 1.8g of photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name : 184), diluted with 80g of a mixed solvent comprising butanone and isopropanol in a relative weight amount of 7:3 to obtain a coating material, and the material was fully dispersed evenly under high shear.

[0036] The prepared coating composition was applied to one side of a biaxially stretched transparent polyester film (manufactured by Toyobo Co., Ltd.). At 80°C, after drying the formed coating for 1.5min, at 300mj / cm 2 ...

Embodiment 2

[0038]

[0039] To 20g of dipentaerythritol penta- and hexaacrylate and 2g of perfluoroalkyl sulfonic acid, add 3g of nano-silver wire (Suzhou Lengshi Nano Material Technology, the average wire diameter is 40nm) and 10g of silica sol (manufactured by Nissan Chemical Co., Ltd. , with an average particle size of 0.02 μm), and added 1 g of polyester-modified hydroxyl-functional polydimethylsiloxane (manufactured by BYK Chemicals, trade name: BYK370) and 1.0 g of photoinitiator (provided by Tianjin Tianjiao Chemical Co., Ltd. Manufactured by the company, trade name: 184), diluted with 60g of a mixed solvent containing butanone and isopropanol with a relative weight dosage of 7:3 to obtain a coating material, and the material was fully dispersed evenly under high shear.

[0040] The prepared coating composition was applied to one side of a biaxially stretched transparent polyester film (manufactured by Toyobo Co., Ltd.). At 80°C, after drying the formed coating for 1.5min, at 30...

Embodiment 3

[0042]

[0043] To 35g of dipentaerythritol penta- and hexaacrylate and 6g of perfluoroalkyl sulfonic acid, add 1g of nano-silver wire (Suzhou Lengshi Nano Material Technology, the average wire diameter is 40nm) and 3g of silica sol (manufactured by Nissan Chemical Co., Ltd. , with an average particle size of 0.03 μm), and added 1.5 g of polyester-modified hydroxyl-functional polydimethylsiloxane (manufactured by BYK, trade name: BYK370) and 0.2 g of photoinitiator (provided by Tianjin Tianjiao Chemical Co., Ltd., trade name: 184), diluted with 40g of a mixed solvent containing butanone and isopropanol with a relative weight amount of 7:3, to obtain a coating material, and the material was fully dispersed evenly under high shear.

[0044] The prepared coating composition was applied to one side of a biaxially stretched transparent polyester film (manufactured by Toyobo Co., Ltd.). After drying the formed coating at 80°C for 1.5min, at 300mj / cm 2 The amount of light is cure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com