Distillation tower top reflux system and distillation tower top reflux method

A distillation column and reflux pump technology, applied in the field of reflux system at the top of distillation column, can solve the problems of stress analysis and structural design of unfavorable supports, inability to accurately control the reflux flow at the top of the column, and high input cost of large-diameter pipes, and achieve precise control. The effect of return flow at the top of the tower, small footprint, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

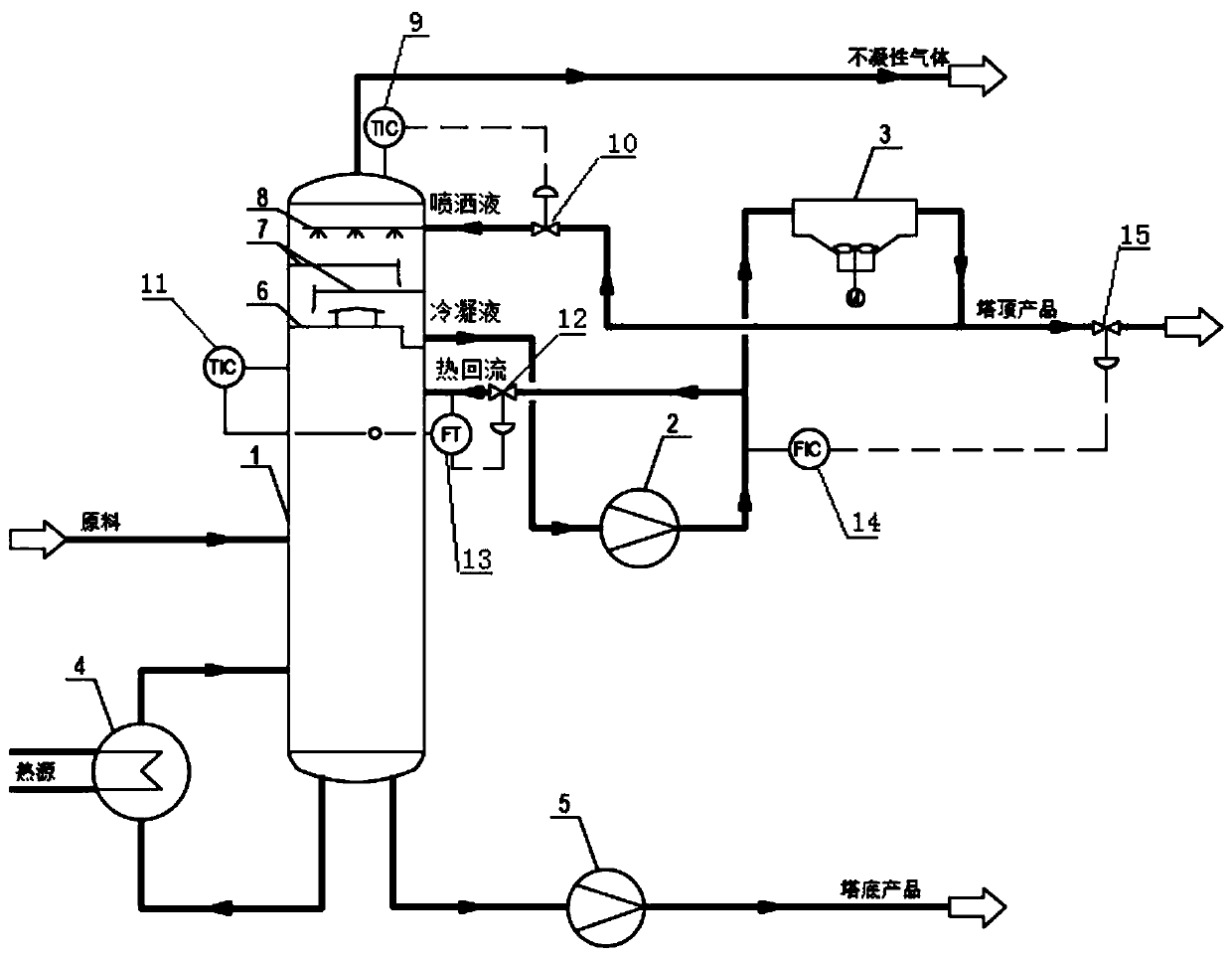

[0023] Such as figure 1 As shown, the reflux system at the top of a distillation tower according to the present invention includes a distillation tower 1, the top of the distillation tower 1 is provided with a non-condensable gas outlet, the middle part is provided with a raw material inlet, and the bottom is provided with a bottom reboiler 4 and a tower The bottom product extraction outlet, the tower bottom product extraction outlet is connected to the tower bottom product pipeline, and the tower bottom product pipeline is provided with a tower bottom product extraction pump 5; it also includes a reflux pump 2 and an air cooler 3; the top of the distillation tower 1 is provided with a temperature display And control device one 9, the top of distillation tower 1 is provided with spraying device 8, tray 7 and broken tower tray 6 successively from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com