Treatment device for exhaust gas produced during processing of backlight assembly used for liquid crystal module (LCM)

A waste gas treatment device and waste gas treatment technology, which are used in transportation and packaging, dispersed particle filtration, dispersed particle separation, etc. to avoid damage, improve filtering effect, and improve utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

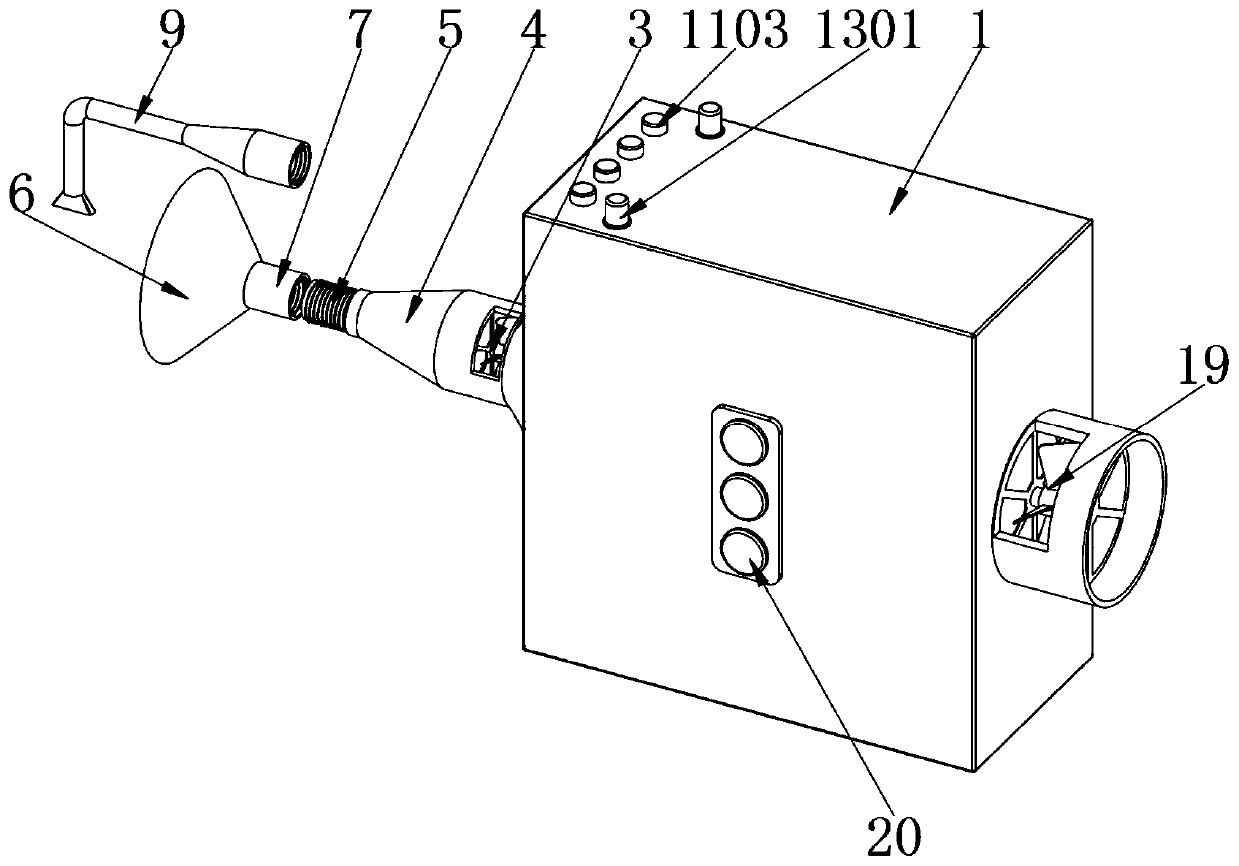

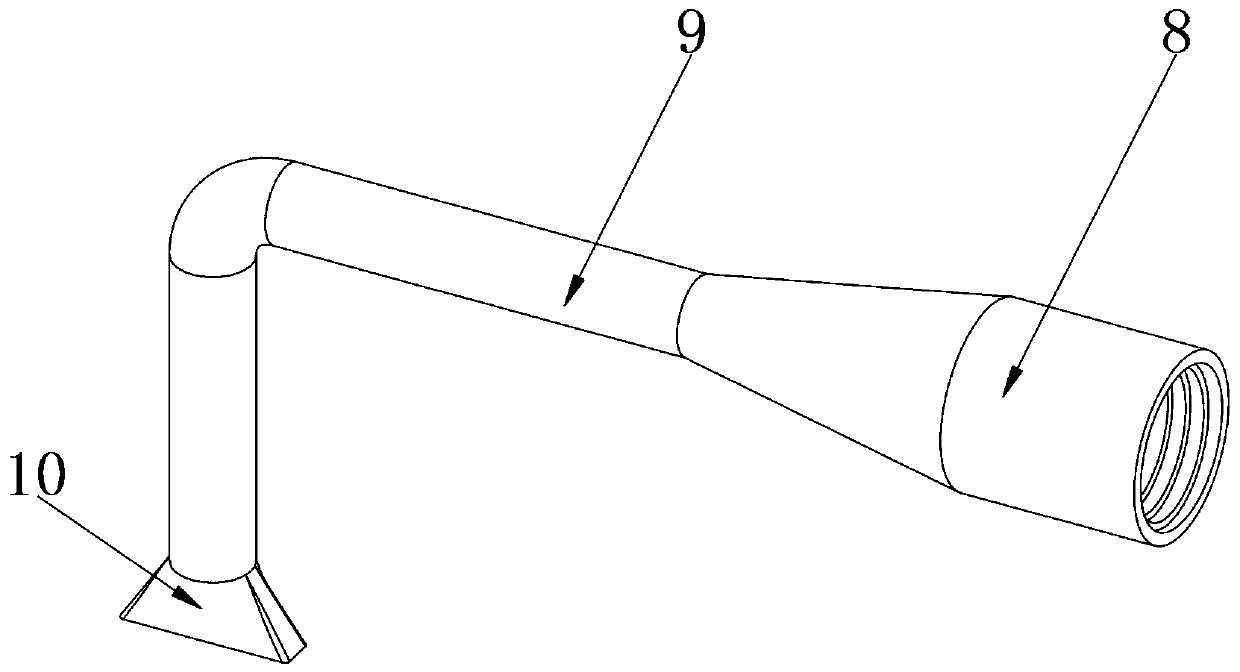

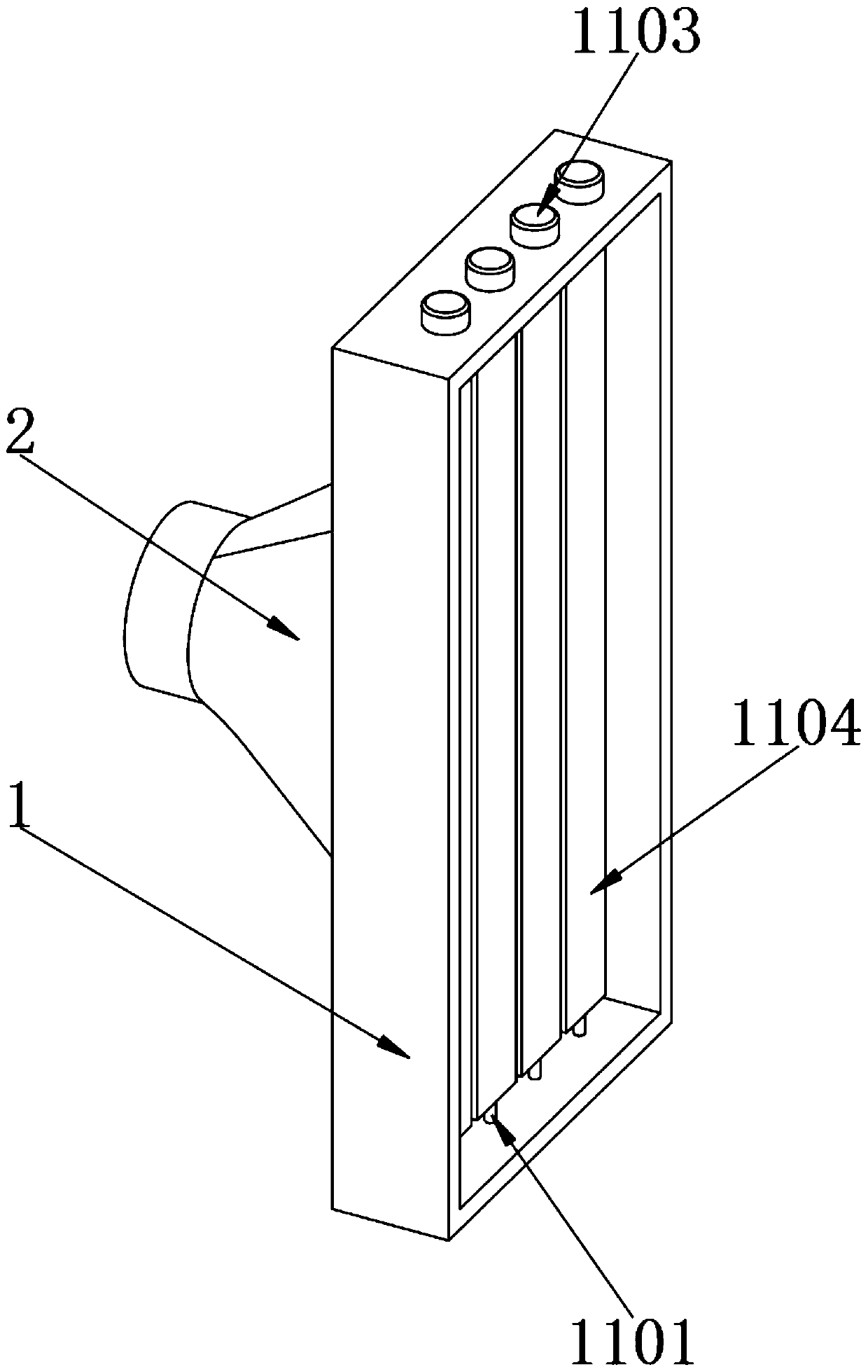

[0032] Example: such as Figure 1-7 As shown, the present invention provides a technical solution for the processing waste gas processing device of the backlight assembly of the LCM liquid crystal module, including the waste gas treatment box 1, and the control switch 20 is fixedly installed on one side of the waste gas treatment box 1, and the control switch 20 is connected with the The electrical connection of the power supply is used to control the power supply connection of the whole device. The middle part of one end of the waste gas treatment box 1 is fixedly installed with an air intake cover 2. The air intake cover 2 and the exhaust gas treatment box 1 are connected by fixing screws. The air intake cover 2 It is in the shape of a trumpet, so that the exhaust gas entering the exhaust gas treatment box 1 is dispersed more evenly, so that the filtration treatment of the exhaust gas is more sufficient. One end of the intake cover 2 is fixedly installed with an intake fan 3,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap