A new type of blackboard and its manufacturing method

A manufacturing method and technology of blackboards, applied in chemical instruments and methods, lamination auxiliary operations, paper/cardboard layered products, etc., can solve the problems of wasting wood, inability to absorb magnetism, rust, etc., and achieve water resistance and heat resistance Good performance, reduce quality and hardness, and ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

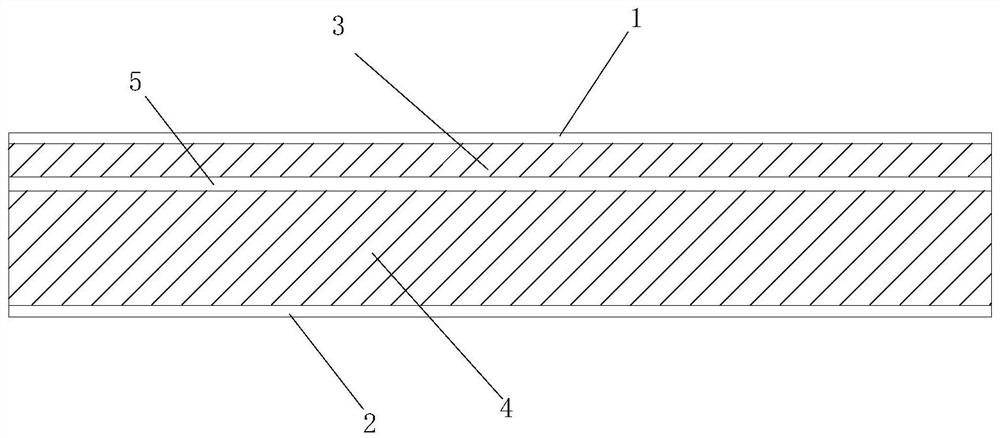

[0021] A new type of blackboard, such as figure 1 As shown, it includes the front decorative paper layer, the front kraft paper layer, the iron-aluminum alloy layer, the rear kraft paper layer, the rear decorative paper layer, the front decorative paper layer, the front kraft paper layer, the iron-aluminum alloy layer, the rear kraft paper layer, and the rear After the decorative paper layers are stacked, they are heat-pressed and formed. The front decorative paper layer and the rear decorative paper layer are coated with a mixture of fluorine-modified acrylic resin, polyurethane acrylic acid, HDDA, and TMPTA, and the surface is first cured by an excimer UV lamp, and then EB Obtained after solidification.

Embodiment 2

[0023] The manufacture method of above-mentioned novel blackboard comprises the steps:

[0024] A. Prepare the front decorative paper layer and the rear decorative paper layer: impregnate the decorative paper with trimethylolpropane triacrylate, then dry it, and then coat it with fluorine-modified acrylic resin, polyurethane acrylic acid, trimethylolpropane triacrylate , the mixed solution of 1,6-hexanediol diacrylate, the mass percentage of fluorine-modified acrylic resin in the mixed solution is 25%, the mass percentage of polyurethane acrylic acid is 30%, the mass percentage of trimethylolpropane triacrylate The mass percentage of 1,6-hexanediol diacrylate is 30%; Utilize the excimer UV lamp to UV-cure the coated decorative paper, then perform EB curing, and then cut to obtain the required size decorative paper layer;

[0025] B. Prepare the front kraft paper layer and the back kraft paper layer: impregnate the kraft paper with phenolic resin. When the kraft paper is impre...

Embodiment 3

[0030] The manufacture method of above-mentioned novel blackboard comprises the steps:

[0031] A. Prepare the front decorative paper layer and the rear decorative paper layer: impregnate the decorative paper with trimethylolpropane triacrylate, then dry it, and then coat it with fluorine-modified acrylic resin, polyurethane acrylic acid, trimethylolpropane triacrylate , the mixed solution of 1,6-hexanediol diacrylate, the mass percentage of fluorine-modified acrylic resin in the mixed solution is 40%, the mass percentage of polyurethane acrylic acid is 15%, the mass percentage of trimethylolpropane triacrylate The mass percentage of 1,6-hexanediol diacrylate is 35%; the coated decorative paper is UV-cured by an excimer UV lamp, then EB-cured, and then cut to obtain the required size decorative paper layer;

[0032] B. Prepare the front kraft paper layer and the back kraft paper layer: impregnate the kraft paper with phenolic resin. When the kraft paper is impregnated with ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com