Sun gear for boosting bicycle and manufacturing method thereof

A technology for assisting bicycles and a manufacturing method, which is applied to vehicle components, vehicle gearboxes, wheel transmissions, etc., can solve the problems of reduced gear accuracy, large gear runout, low gear tooth profile and tooth direction accuracy, etc., to reduce noise and The effect of vibration, reducing welding workload and eliminating deformation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

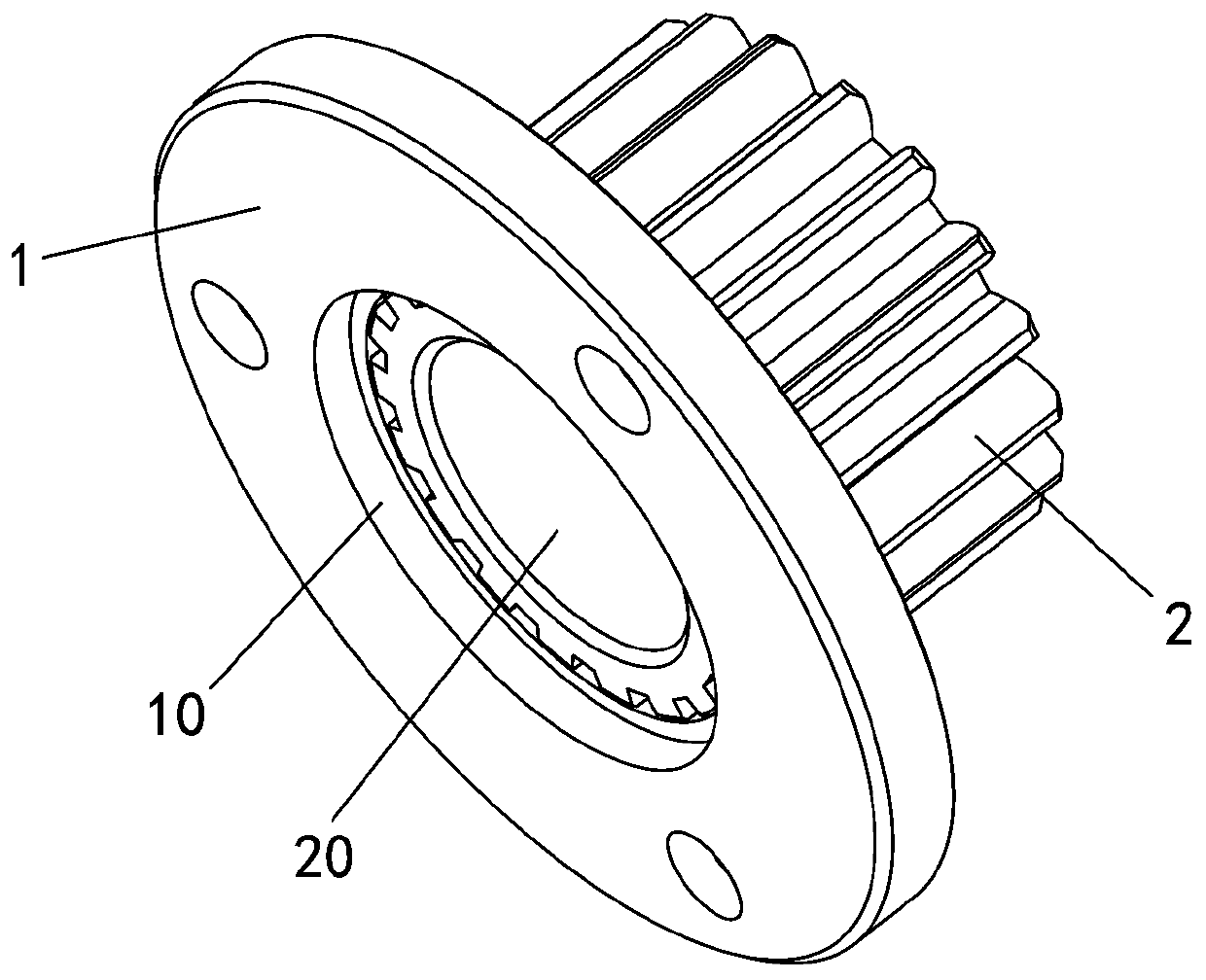

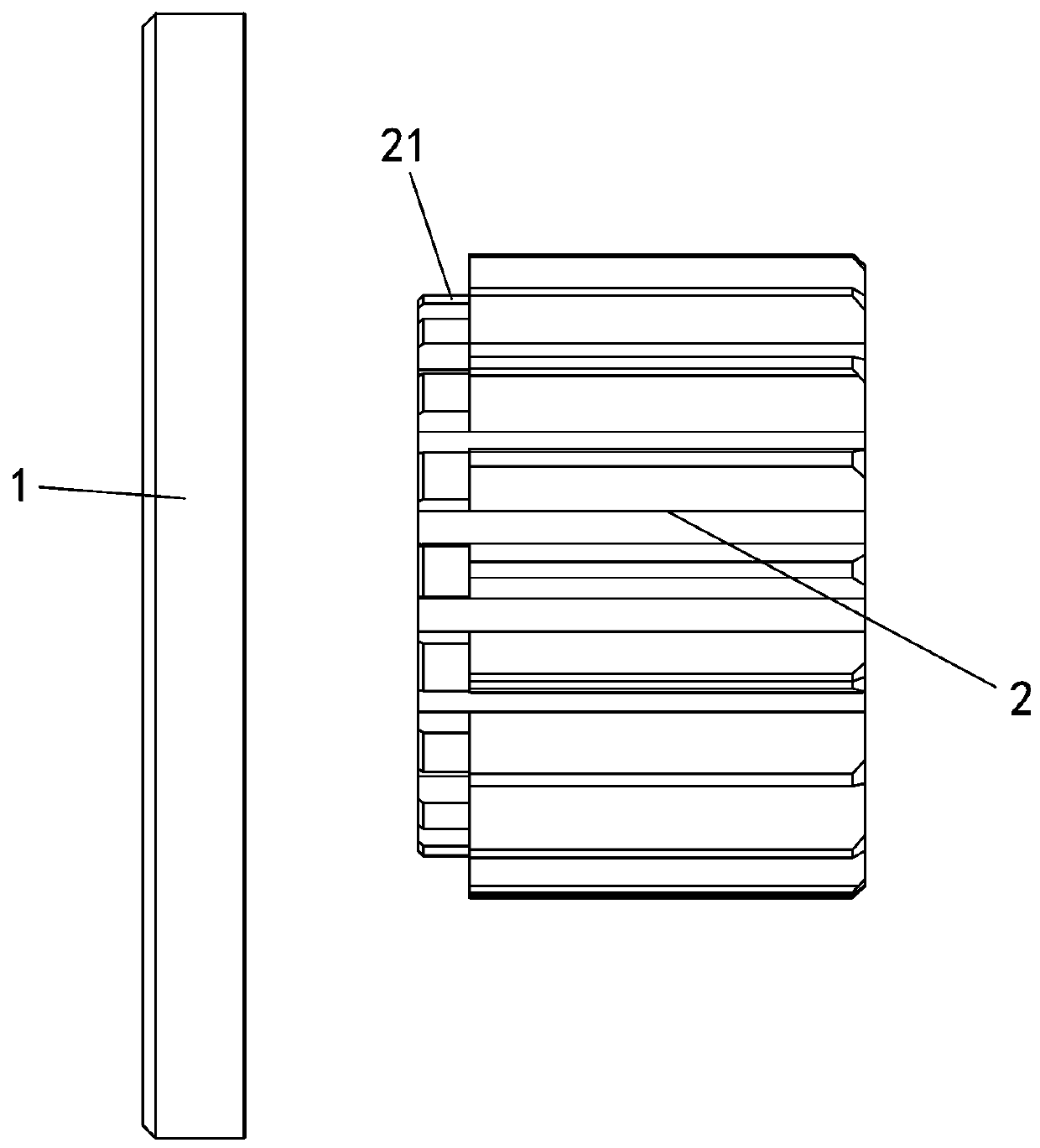

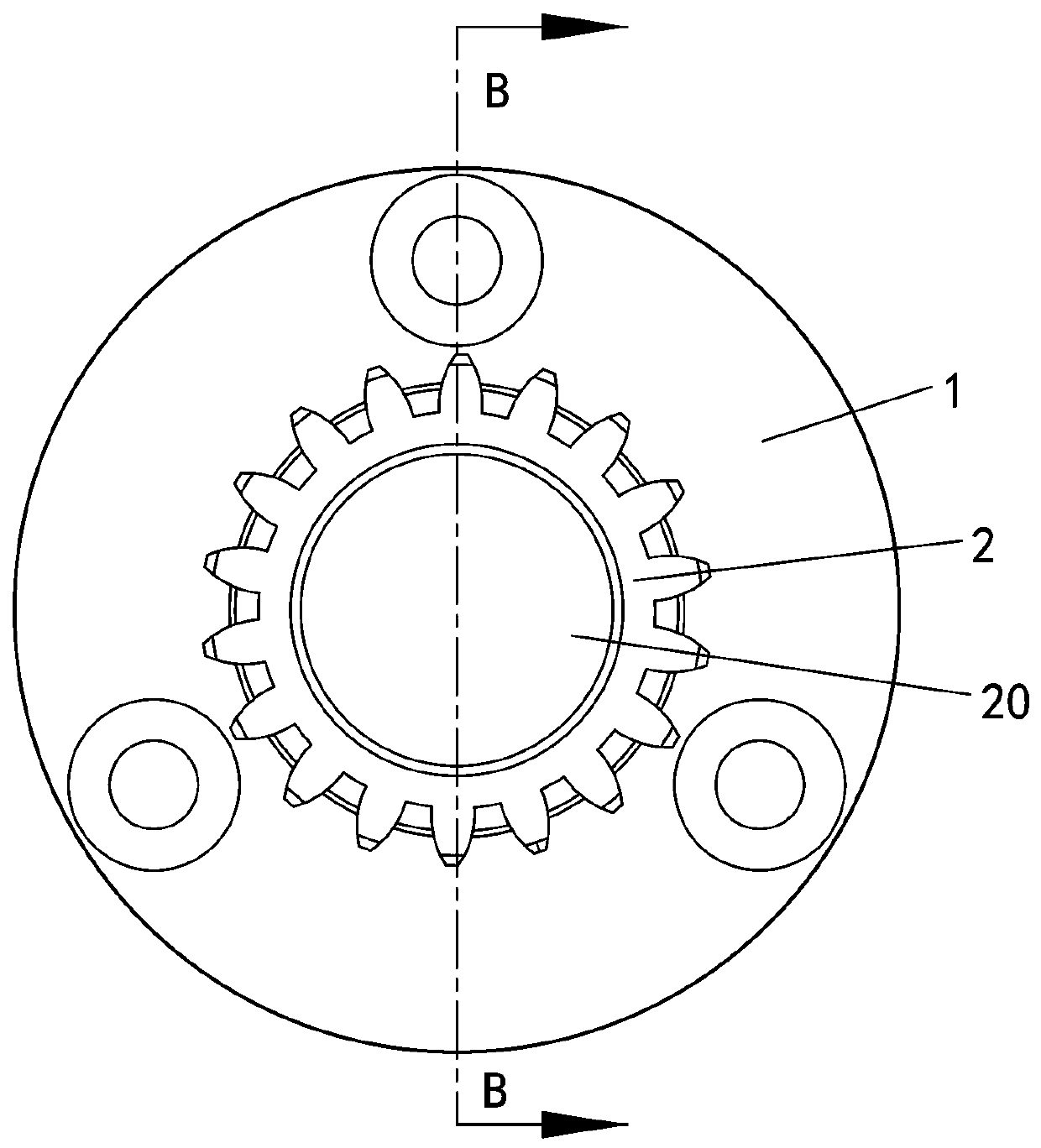

[0029] Embodiment one, see Figure 1 to Figure 4 As shown, a sun wheel for power-assisted bicycles includes a flange 1 and a gear 2. The center of the flange 1 is provided with a stepped hole 10. The stepped hole 10 includes a first section hole 11 and a second section hole. The first section hole The diameter of 11 is greater than the diameter of the second section hole 12, and the thickness of the first section hole 11 and the second section hole 12 are equal; one end of the gear 2 is provided with a step portion 21, and the step portion 21 of the gear 2 is higher than the teeth of the gear 2 On the bottom surface of the groove, the stepped portion 21 of the gear 2 is inserted into the second-stage hole 12, and a welding spot is set between the stepped portion 21 and the end face of the flange 1 close to the second-stage hole 12, so as to weld the flange 1 and the gear 2 into a Sun gear.

[0030] The manufacturing method of the above-mentioned sun gear for power-assisted bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com