Chloride-free alkali-free liquid setting accelerator and preparation method thereof

A technology of liquid accelerator and stabilizer, applied in the field of chlorine-free and alkali-free liquid accelerator and its preparation, can solve the problems of strong corrosion, large loss of concrete strength, long shelf life, etc. Small, the effect of increasing the coagulation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

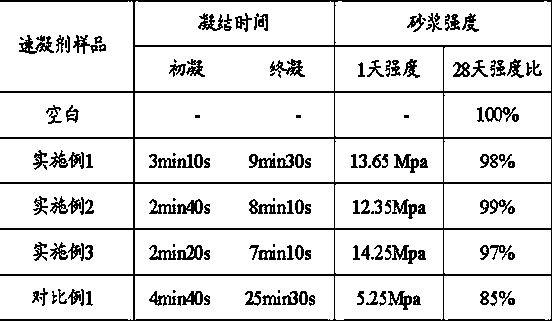

Examples

Embodiment 1

[0031] A preparation method of chlorine-free and alkali-free liquid quick-setting agent, comprising the following steps:

[0032] Step 1, preparation of aluminum fluorosilicate: add 48% fluorosilicic acid, 32% aluminum hydroxide (industrial first-grade product) and 20% tap water to the reactor, heat and stir at a temperature of 60°C and a speed of 400 rpm 1.5h, aluminum fluorosilicate was obtained.

[0033] Step 2: Mix 10% aluminum fluorosilicate with 30% water, stir and react for 40 minutes at a temperature of 60°C and a rotational speed of 400 rpm to completely dissolve the aluminum fluorosilicate to obtain an aluminum fluorosilicate solution.

[0034] Step 3: Add 50% aluminum sulfate octadecahydrate to the aluminum fluorosilicate solution, and continue stirring for 55 minutes at a temperature of 60°C and a rotation speed of 400 rpm to obtain a stirring solution.

[0035] Step 4, add 5% diethanol monoisopropanolamine, 1% dodecyl dimethyl amine oxide and the remaining water ...

Embodiment 2

[0037] A preparation method of chlorine-free and alkali-free liquid quick-setting agent, comprising the following steps:

[0038] Step 1, preparation of aluminum fluorosilicate: add 48% fluorosilicic acid, 32% aluminum hydroxide (industrial first-grade product) and 20% tap water to the reactor, heat and stir at a temperature of 60°C and a speed of 400 rpm 1h, aluminum fluorosilicate was obtained.

[0039] Step 2: Mix 20% aluminum fluorosilicate with 30% water, stir and react for 40 minutes at a temperature of 60°C and a rotational speed of 400 rpm to completely dissolve the aluminum fluorosilicate to obtain an aluminum fluorosilicate solution.

[0040] Step 3: Add 40% aluminum sulfate octadecahydrate to the aluminum fluorosilicate solution, and continue stirring for 55 minutes at a temperature of 60°C and a rotation speed of 400 rpm to obtain a stirring solution.

[0041] Step 4: Add 3% diethanol monoisopropanolamine, 1.5% dodecyl dimethyl amine oxide and the remaining water ...

Embodiment 3

[0043] A preparation method of chlorine-free and alkali-free liquid quick-setting agent, comprising the following steps:

[0044] Step 1, preparation of aluminum fluorosilicate: add 53% fluorosilicic acid, 37% aluminum hydroxide (industrial first-grade product) and 10% tap water into the reactor, heat and stir at a temperature of 60°C and a speed of 400 rpm 2h, in aluminum fluorosilicate.

[0045] Step 2: Mix 20% aluminum fluorosilicate with 30% water, stir and react for 40 minutes at a temperature of 60°C and a rotational speed of 400 rpm to completely dissolve the aluminum fluorosilicate to obtain an aluminum fluorosilicate solution.

[0046] Step 3: Add 40% aluminum sulfate octadecahydrate to the aluminum fluorosilicate solution, and continue stirring for 55 minutes at a temperature of 60°C and a rotation speed of 400 rpm to obtain a stirring solution.

[0047] Step 4, add 5% diethanol monoisopropanolamine, 1% dodecyl dimethyl amine oxide and the remaining water to the sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com