Method for preparing cannabidiol

A technology of cannabidiol and cannabis, which is applied in the field of preparation of cannabidiol, can solve problems affecting cannabidiol, cannabidiol destruction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

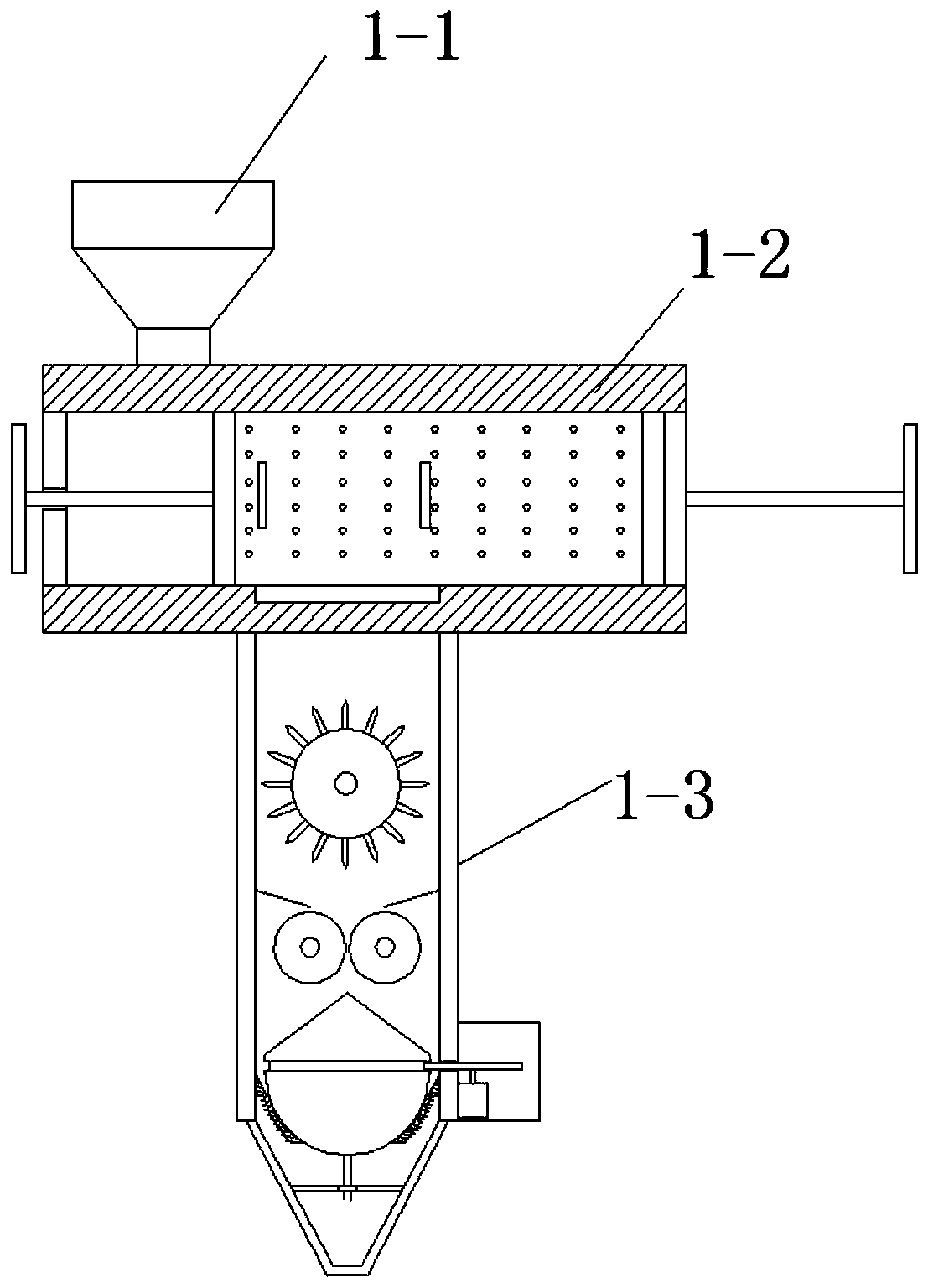

[0054] This embodiment is a kind of preparation equipment embodiment of cannabidiol.

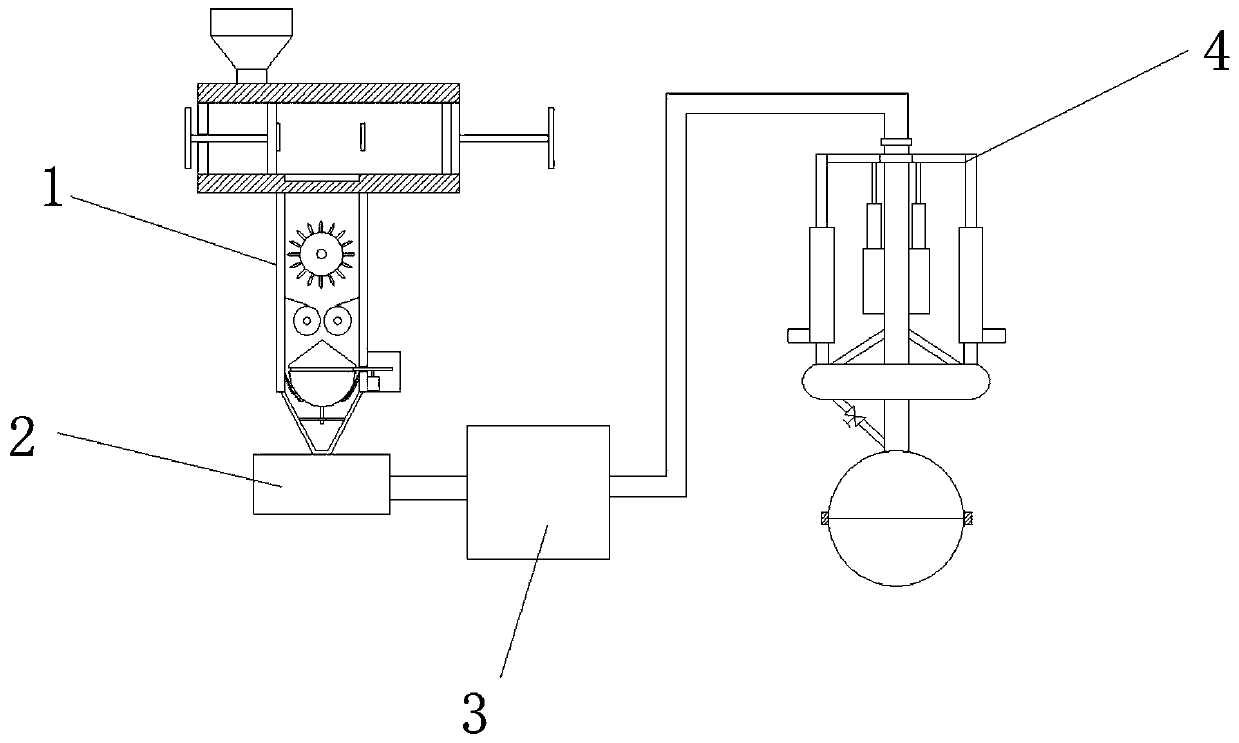

[0055] Such as figure 1 and 2 As shown, a preparation device for cannabidiol disclosed in this embodiment includes a pre-processing device 1, a drying device 2, an extraction device 3, a concentration device 4 and a post-processing device; the pre-processing device 1 passes through the drying device 2 and The extraction device 3 is connected, and the extraction device 3 is connected with the post-processing device through the concentration device 4;

[0056] Firstly, the mosaic and leaves of the female cannabis plants are picked and sorted, and the diseased plants are removed to obtain production materials. The leaves of the selected production raw materials are frozen and pulverized through the pre-processing device 1, and the pulverized raw materials are dried in the drying device 2. Dried into powder, the powder is made into an extract through the extraction device 3, and then the extra...

specific Embodiment approach 2

[0062] This embodiment is an embodiment of the preparation equipment of cannabidiol.

[0063] combine Figure 5 , 6 , 7, this embodiment is based on the specific implementation mode 1, the difference is that the cooling device 1-2 includes a cooling box 1-2-1, a partition 1-2-2, a sealing plate 1- 2-3, the first push plate 1-2-4, the first T-bar 1-2-5, the second push plate 1-2-6 and the second T-bar 1-2-7; the cooling box The upper end of the body 1-2-1 is provided with a feed port 1-1, and the lower end is provided with a crushing device 1-3, and the two ends of the cooling box 1-2-1 are symmetrically provided with partitions 1-2-2, and the partitions 1-2-2 has a threaded hole, and the lower end surface of the cooling box 1-2-1 has a discharge hole, and the cooling box 1-2-1 passes through the discharge hole and the crushing device 1-3 The upper end of the discharge hole is provided with a sealing plate 1-2-3, the upper end of the discharge hole is symmetrically provided ...

specific Embodiment approach 3

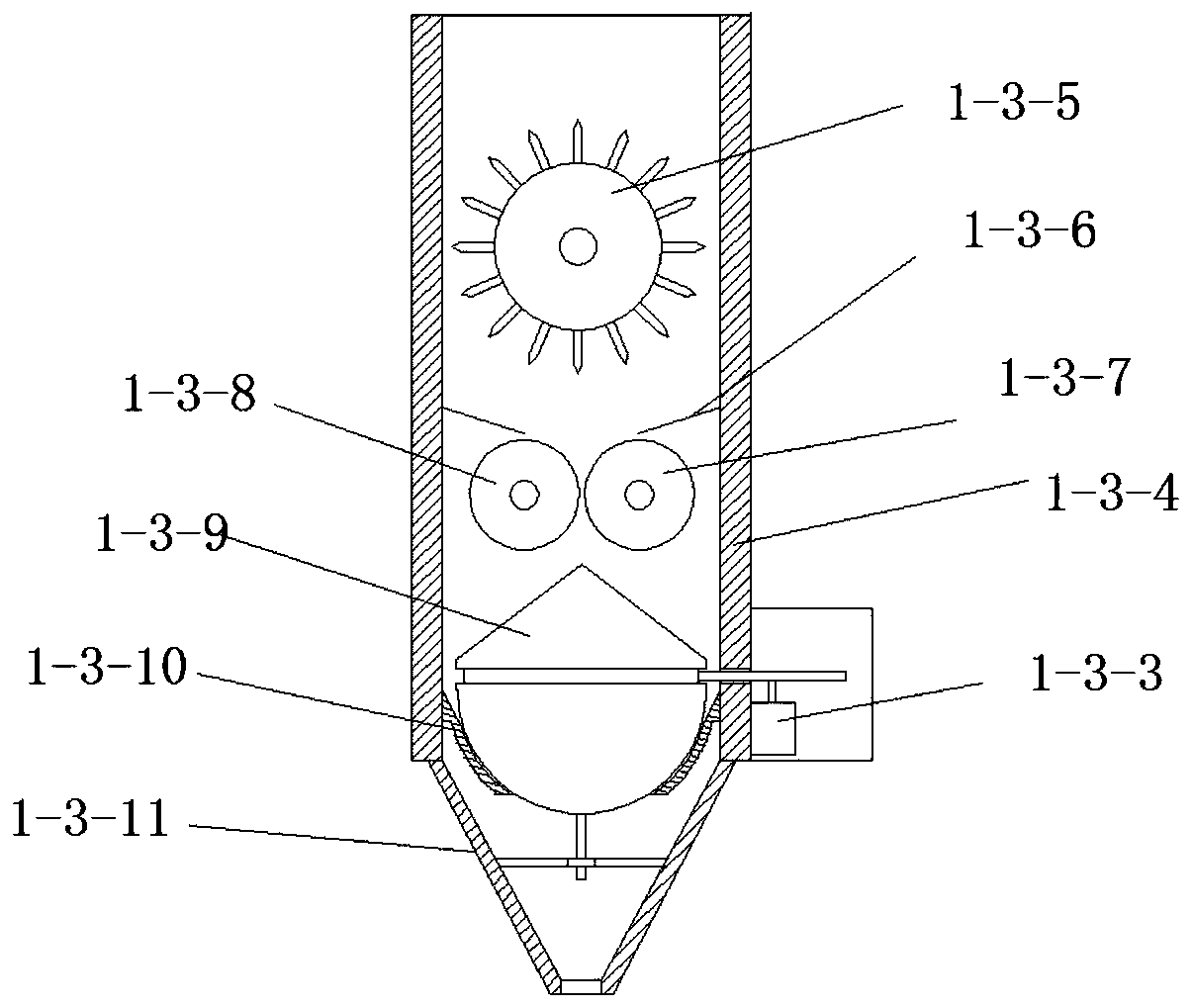

[0066] This embodiment is an embodiment of a crushing device for the preparation of cannabidiol. It should be noted that the pulverizing device for the preparation of cannabidiol in this embodiment can be implemented separately, that is, as a part of the preparation equipment for cannabidiol, it can be used for the preparation of cannabidiol. A device for preparing cannabidiol is further defined.

[0067] Such as figure 2 , 3 , 4, a crushing device for the preparation of cannabidiol disclosed in this embodiment includes a first motor 1-3-1, a second motor 1-3-2, a third motor 1-3-3, a crushing Box 1-3-4, with rotating roller 1-3-5, drainage sheet 1-3-6, active pressure roller 1-3-7, driven pressure roller 1-3-8, grinding table 1-3- 9. Grinding photo 1-3-10 and conical funnel 1-3-11; the first motor 1-3-1, the second motor 1-3-2 and the third motor 1-3-3 are respectively set in On the outer wall of the crushing box 1-3-4, a rotating roller 1-3-5, a drainage piece 1-3-6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com