Concrete surface waterproof coating and preparation method and application thereof

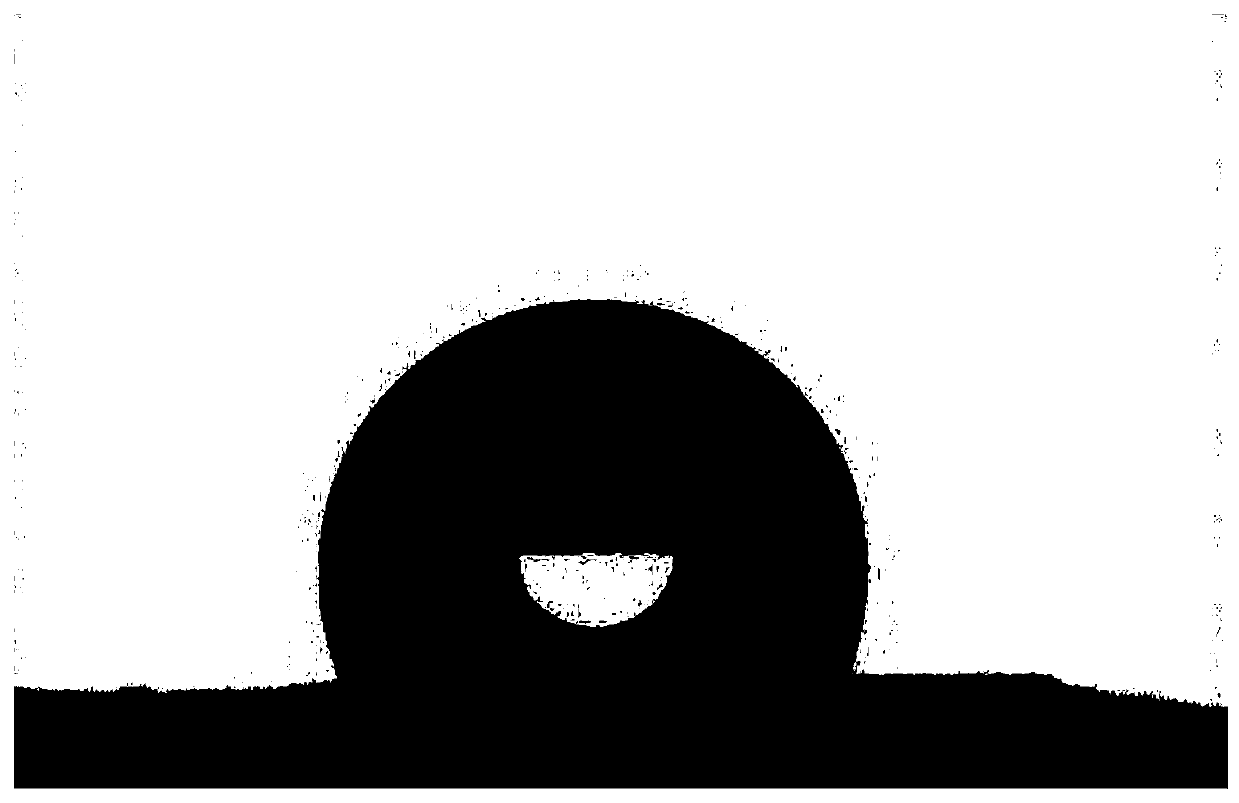

A technology of concrete surface and waterproof coating, applied in the direction of coating, etc., can solve the problems of complicated process, time-consuming preparation, high production cost, etc., and achieve the effect of simple preparation process, easy control and good film-forming property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

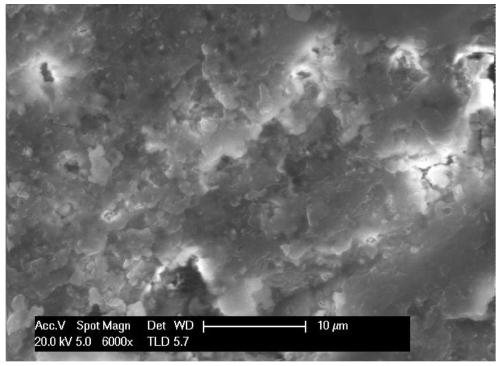

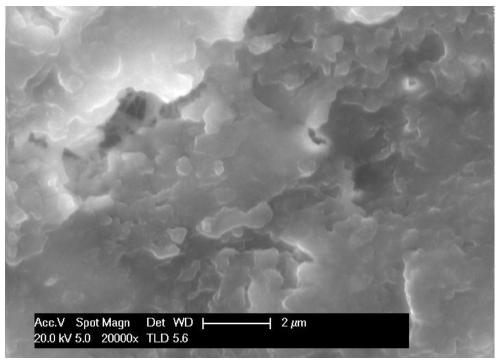

Method used

Image

Examples

Embodiment 1

[0048] Weigh 600g of deionized water, 24g of water-soluble PVA fiber, 49.8g of polymethylhydrogensiloxane and 15g of metakaolin powder;

[0049] Each above-mentioned component is made the required concrete surface waterproof coating of the present invention by following steps:

[0050] (1) Dissolve the 90-degree water-soluble PVA fiber measured as 24g in deionized water with a quality of 550g, and heat it in a 100° water bath for 2h to obtain the PVA aqueous solution; Hydrogen siloxane, then disperse at 5000rpm for 5min, then adjust the speed to 6000rpm and disperse for 5min to obtain PVA / siloxane polymer emulsion;

[0051] (2) Dissolve the metakaolin powder measured as 15g in 50g deionized water, ultrasonically disperse for 1h and magnetically stir for 1h to obtain a uniformly dispersed metakaolin solution;

[0052] (3) Slowly add the dispersed metakaolin solution into the above-mentioned PVA / siloxane polymer emulsion, and disperse at 5000 rpm for 10 minutes to obtain a hydr...

Embodiment 2

[0062] Weigh 600 g of deionized water, 30 g of water-soluble PVA fiber, and 60 g of hydroxypolydimethylsiloxane.

[0063] Each above-mentioned component is made the required concrete surface waterproof coating of the present invention by following steps:

[0064] (1) Dissolve the 40-degree water-soluble PVA fiber measured as 30 g in deionized water, and heat it in a 50-degree water bath for 1 hour to obtain an aqueous PVA solution;

[0065] (2) Slowly add 60 g of hydroxyl polydimethylsiloxane to the PVA aqueous solution, then disperse at 5000 rpm for 5 minutes, then adjust the speed to 6000 rpm and disperse for 5 minutes to obtain a PVA / siloxane polymer emulsion. In this embodiment, the PVA / siloxane polymer emulsion is the target product hydrophobic emulsion (waterproof coating for concrete surface) to be prepared.

[0066] It can be seen that the concrete surface waterproof coating (hydrophobic emulsion) prepared in this embodiment includes the following components: 600 g of...

Embodiment 3

[0070] Weigh 600 g of deionized water, 30 g of water-soluble PVA fiber, 42 g of hydroxyl polydimethylsiloxane, and 18 g of silane coupling agent. The silane coupling agent is KH792 or N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane.

[0071] The difference between this example and Example 2 is that the amount of hydroxypolydimethylsiloxane is reduced, and the amount of reduction of hydroxypolydimethylsiloxane happens to be the amount of newly added silane coupling agent.

[0072] Each above-mentioned component is made the required concrete surface waterproof coating of the present invention by following steps:

[0073] (1) Dissolve the 40-degree water-soluble PVA fiber measured as 30 g in deionized water, and heat it in a 50-degree water bath for 1 hour to obtain an aqueous PVA solution;

[0074] (2) Slowly add 42g of hydroxyl polydimethylsiloxane and 18g of silane coupling agent into the PVA aqueous solution, then disperse at 5000rpm for 5min, then adjust the speed to 6000rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com