AS NZS 3678-350L15Z15-Z35 controlled rolling structure steel plate having thickness of 50-80 mm and manufacturing method thereof

A structural and controlled rolling technology, applied in the field of AS/NZS3678-350 series structural steel, can solve the problems of long production cycle and high production cost, and achieve the effect of low production cost, short production cycle and few processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

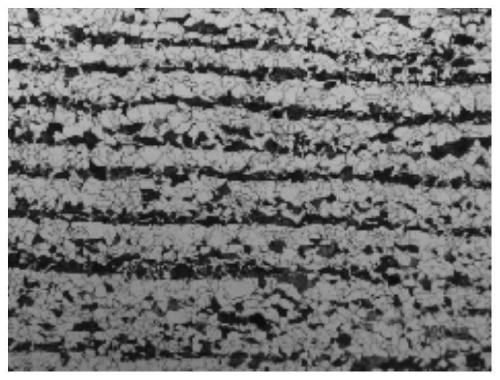

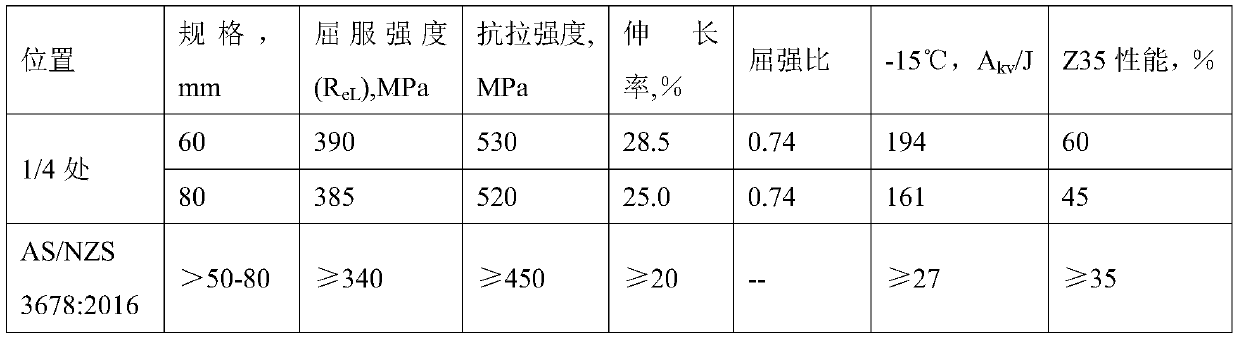

[0033] Example 1: The present invention designs and smelts the AS / NZS 3678-350L15Z35, 370mm thick continuous casting billet provided by the chemical composition, and produces an example of rolling 80mm thick steel plate. The continuous casting slab is 370×2400×3200mm, and the rolled finished plate is 80×3000×L (length) mm. The billet is cold loaded into the heating furnace, the temperature of the preheating section of the heating furnace: 750-800℃, the temperature of the heating section: 900-1200℃, the temperature of the second heating section: 1190-1240℃, the temperature of the soaking section: 1200-1210℃; Total time 396 minutes. Rough rolling is rolled 6 times, and the thickness is 166mm. After warming, the starting temperature of the finishing mill is 810°C. After 8 passes of finishing rolling, the final rolling temperature is 799°C. After rolling, it is straightened by a leveler for 3 After 40 hours, take samples, perform physical and chemical inspection and quality inspe...

Embodiment 2

[0034] Example 2: The present invention designs and smelts the AS / NZS 3678-350L15Z35, 250mm thick continuous casting billet provided by the chemical composition, and produces an example of rolling a 60mm thick steel plate. The continuous casting slab is 250×2400×3500 mm, and the rolled finished plate is 60×2800×L (length) mm. Blank is cold-packed into heating furnace, and heating process is the same as example 1, and total heating time is 286 minutes. Rough rolling is rolled for 5 passes, and the thickness is 115mm. After warming, the starting temperature of the finish rolling mill is 830°C. The finish rolling is rolled for 7 passes, and the final rolling temperature is 790°C. After rolling, it is straightened by a leveler. Send it to the cooling bed for cooling, cool down to 360°C and slowly cool down in the line stack; after 42 hours, take samples, perform physical and chemical inspections and quality inspections. The test results of physical and chemical properties are sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com