Preparation method of hydrophobic nanofilm on plasma chemical vapor deposition fabric wire

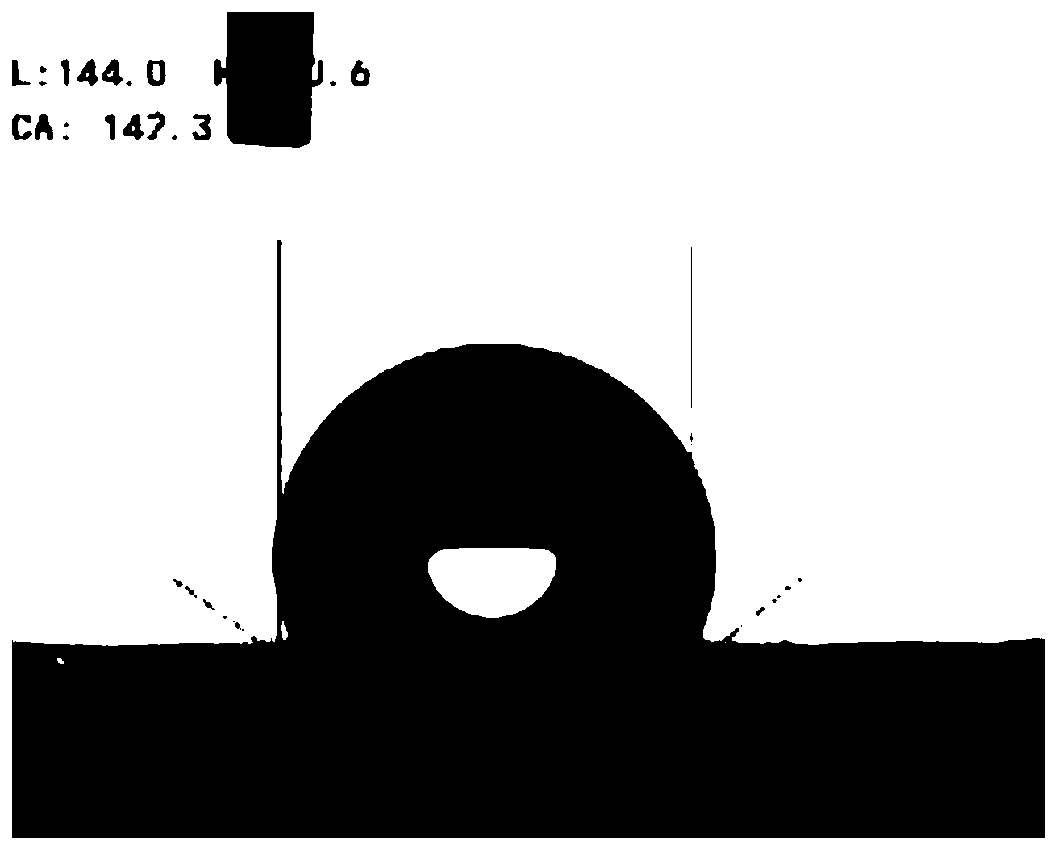

A chemical vapor deposition, plasma gas technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of poor contact, affecting the service life of the wire, corrosion, etc., to reduce the surface energy, improve the surface Water repellency, the effect of improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

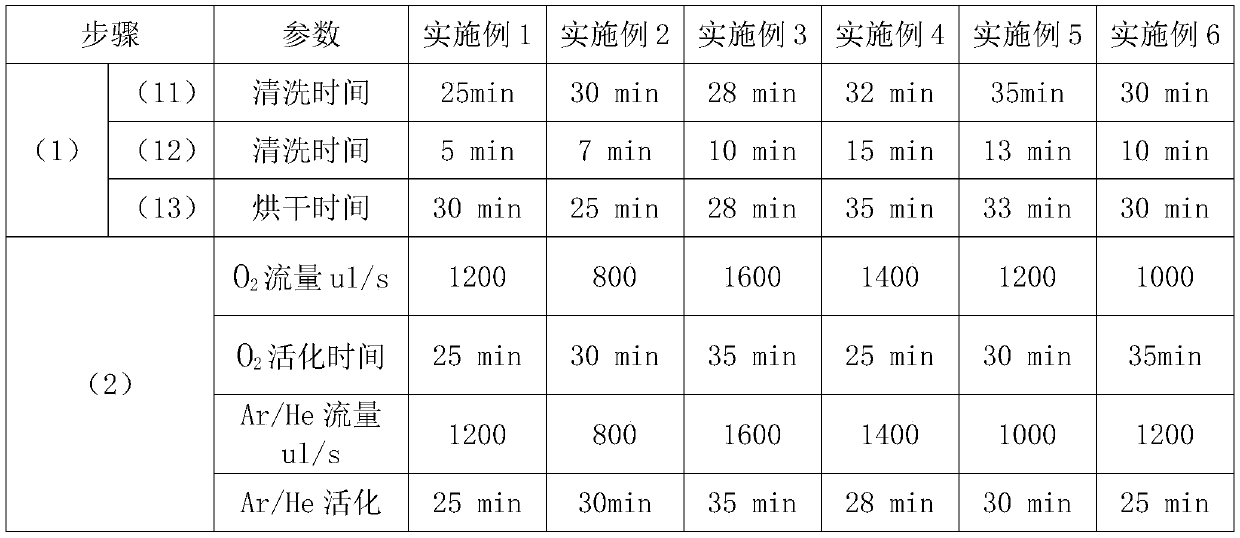

[0034] A preparation method of plasma chemical vapor deposition fabric wire rod nano-hydrophobic film, comprising the following steps:

[0035] (1), pretreatment: ultrasonic surfactant solution cleaning;

[0036] (2) Plasma gas activation treatment: In the reaction chamber, the plasma activated gas processes the cleaned fabric wire;

[0037] (3) Coating: The vaporized coating material enters the reaction chamber, and under vacuum, the plasma gas carrier gas collides with the vaporized coating material, and deposits a nano-film on the surface of the fabric wire;

[0038] (4) Purification: break the vacuum in the reaction chamber;

[0039] (5) Post-processing: take out the fabric wire coated with the nano-film in the reaction chamber, and perform sealing and packaging treatment.

[0040] The invention is to coat a hydrophobic film on braided electronic wires. The outer fabric of these electronic wires is usually made in a variety of colors, mostly dark colors such as black an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com