Apparatus and method for ferrate preparation

A ferrate and tank technology, applied in chemical instruments and methods, water treatment parameter control, polluted groundwater/leachate treatment, etc. Achieve the effect of small footprint of the device, lower tank voltage, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

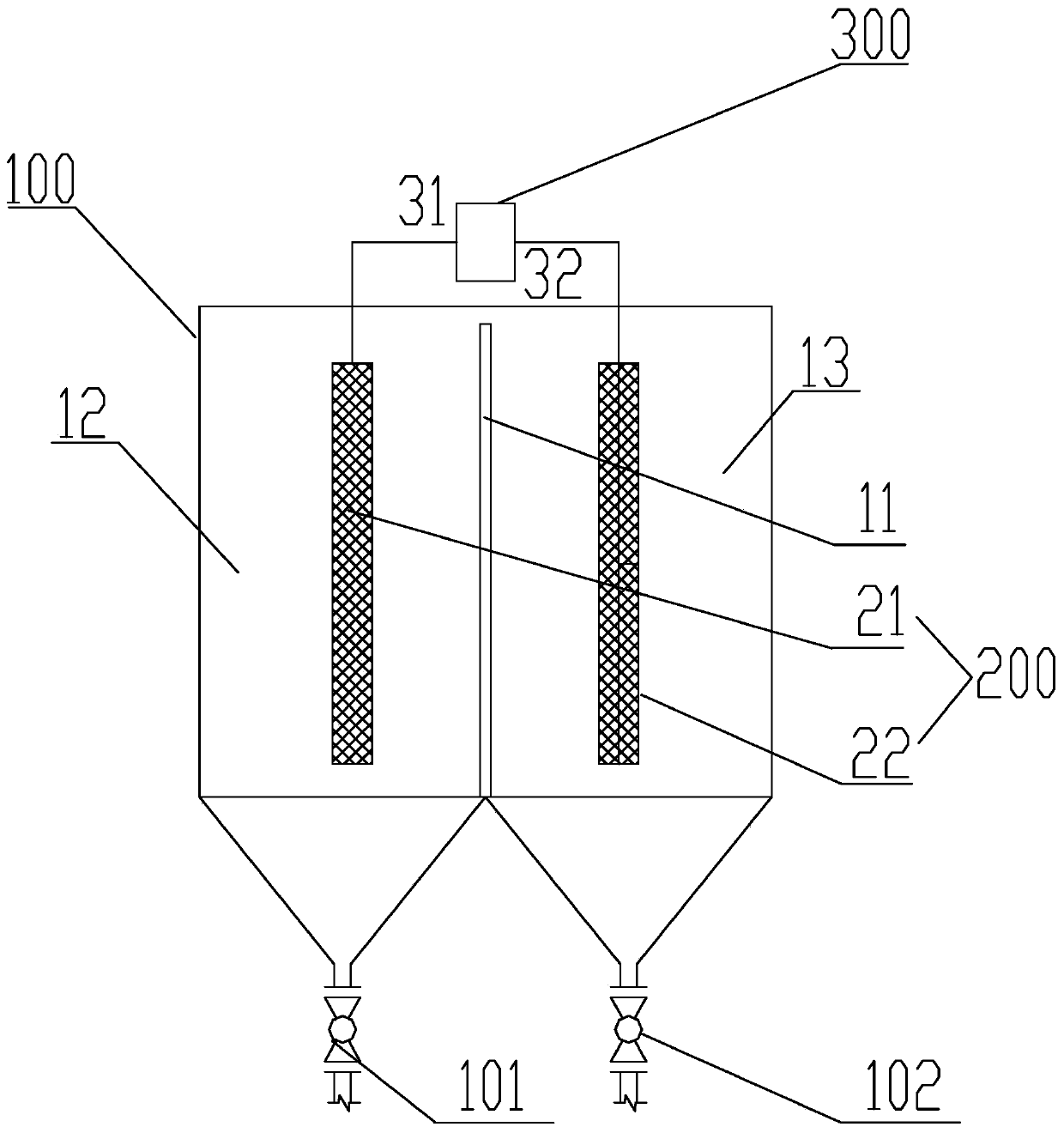

[0035] According to the device for preparing ferrate according to the embodiment of the present invention, a diaphragm is arranged in the tank body, and the diaphragm divides the tank body into a first reaction zone and a second reaction zone, and sodium hydroxide is respectively set in the first reaction zone and the second reaction zone And / or potassium hydroxide and the first electrolytic basket and the second electrolytic basket, and the first electrolytic basket and the second electrolytic basket are hollow and filled with electrolytic materials, and the first electrolytic basket is electrically connected to the positive pole of the power supply React with the electrolytic material in one of the second electrolytic baskets: Fe+8OH - = FeO 4 2- +4H 2 O+6e - , while the reaction occurs at the other of the first and second electrolytic baskets electrically connected to the negative pole of the power supply: 6H 2 O+6e - =3H 2 +6OH - , the total reaction is Fe+2OH - +2...

Embodiment 1

[0041] Add sodium hydroxide solution / or potassium hydroxide solution (concentration is 18mol / L) respectively in the tank body of the present application, the first electrolysis basket is made of stainless steel, and the electrolytic material in the first electrolysis basket is pure iron, the second The second electrolysis basket is made of graphite, the electrolysis material in the second electrolysis basket is carbon steel, the positive electrode of the commutation power supply is periodically electrically connected with one of the first electrolysis basket and the second electrolysis basket, The negative electrode is periodically electrically connected to the other of the first electrolysis basket and the second electrolysis basket, and the current density of the electrolysis reaction is 50A / m 2 , the temperature is 50 degrees Celsius, and the reversing period of the reversing power supply is 30min. Sodium ferrate is collected under the electrolytic basket as the anode, and t...

Embodiment 2

[0043] Add potassium hydroxide solution (concentration is 14mol / L) respectively in the tank body of the present application, the first electrolysis basket is made of titanium, and the electrolysis material in the first electrolysis basket is iron-carbon alloy, the second electrolysis basket The basket is made of copper, the electrolytic material in the second electrolysis basket is pure iron, the positive pole of the commutation power supply is periodically electrically connected with one of the first electrolysis basket and the second electrolysis basket, and the negative pole of the commutation power supply is periodically The other one of the first electrolysis basket and the second electrolysis basket is electrically connected, and the current density of the electrolysis reaction is 500A / m 2 , the temperature is 20 degrees Celsius, the reversing period of the reversing power supply is 120min, and the potassium ferrate is collected under the electrolytic basket as the anode,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com