Weather-resistant electrophoretic wood grain aluminum profile production process and aluminum profile prepared through same

A production process and technology for aluminum profiles, applied in the field of aluminum profiles, can solve the problems of poor weather resistance, affect the decorative effect, blurred wood grain patterns, etc., and achieve the effect of good coverage, smooth and clean film surface, and completely clear transfer printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

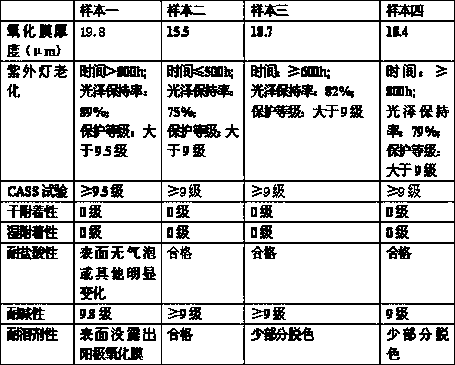

Examples

Embodiment 1

[0024] The production process of weather-resistant electrophoretic wood-grain aluminum profiles is realized through the following steps:

[0025] S1: After deburring the surface of the aluminum profile, place it in a degreasing tank at 40°C and soak for 2 minutes at room temperature to complete the degreasing process. Sulfuric acid 160 g / L; lift out after oil removal, enter the washing tank, and enter the next process after washing twice;

[0026] S2: Dry the aluminum profile processed in step S1 until there is no obvious moisture on the surface, then put it into the acid etching tank and soak for 10 minutes at 30°C to complete the acid etching process, in which the composition of the acid etching tank liquid is 60 g of ammonium bifluoride / L; enter another washing tank after acid etching, and enter the next process after washing once;

[0027] S3: Put the aluminum profiles that have passed step S2 into the alkali etching tank at 35°C for soaking and alkali etching. The alkal...

Embodiment 2

[0036] S1: After deburring the surface of the aluminum profile, place it in a degreasing tank at 40°C and soak for 2 minutes at room temperature to complete the degreasing process. Sulfuric acid 210 g / L; lift out after oil removal, enter the washing tank, and enter the next process after washing twice;

[0037] S2: Dry the aluminum profile treated in step S1 until there is no obvious moisture on the surface, then put it into the acid etching tank and soak it at 45°C for 3 minutes to complete the acid etching process, in which the composition of the acid etching tank liquid is 40 g of ammonium bifluoride / L; enter another washing tank after acid etching, and enter the next process after washing once;

[0038] S3: Put the aluminum profiles that have passed step S2 into the alkali etching tank at 35-50°C for soaking and alkali etching. The alkali etching time depends on the surface treatment requirements. The alkali etching tank liquid is free alkali 40g / L, Al 3+ 40g / L; After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com