Ceramsite concrete plate with skin effect shell structure and processing method of ceramsite concrete plate

A shell structure and skin technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of segregated ceramsite particles, low plate strength, limited application, etc., to improve plane stiffness and strength, reduce The effect of self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The ceramsite concrete panel with skin effect shell structure of the present invention includes a structural frame and ceramsite concrete poured in the structural frame; the structural frame includes a double-sided two-way reinforced truss body and a skin shell structure.

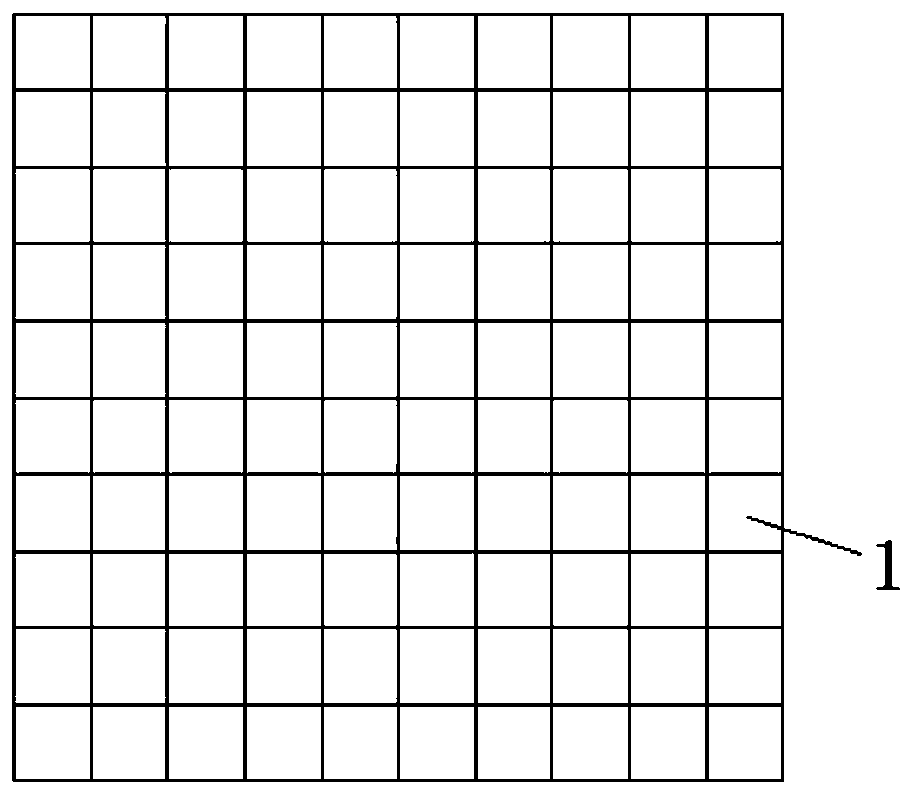

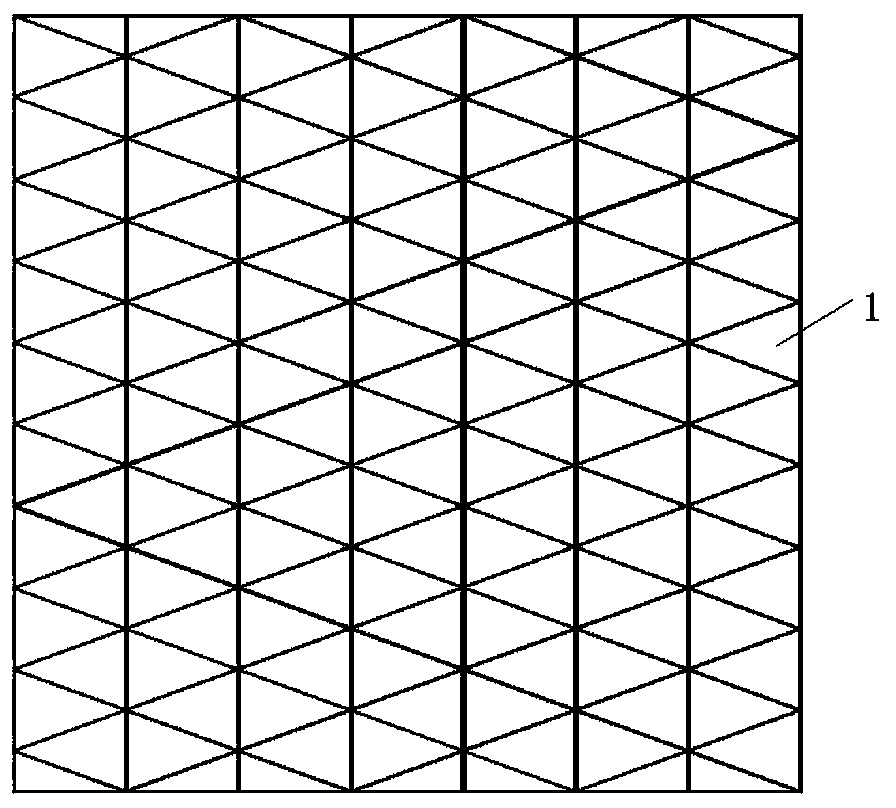

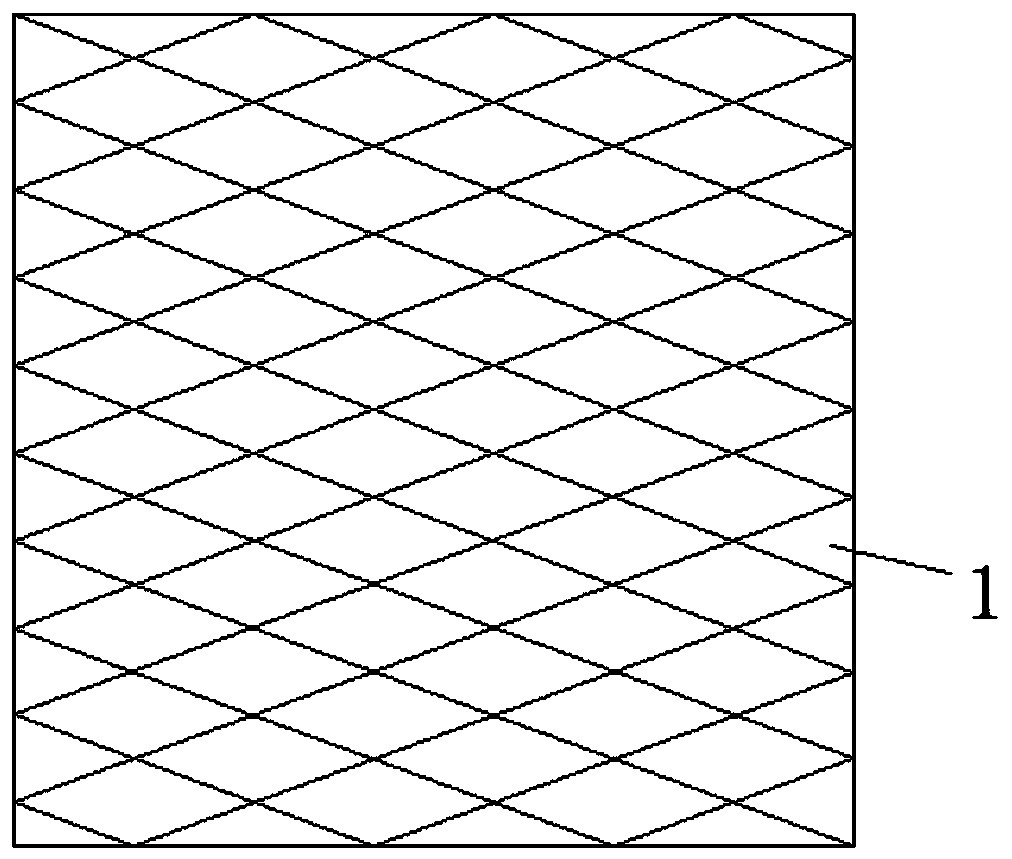

[0048] The double-sided two-way reinforced truss body includes planar steel mesh 1 and corrugated steel mesh 2, such as Figure 1-3 As shown, the planar steel mesh 1 is composed of square grid, triangular grid or rhombus grid; the corrugated steel mesh 2 is formed by bending and pressing the plane steel mesh 1, such as Figure 4 As shown, the planar steel mesh sheet 1 composed of square grids forms a triangular corrugated steel mesh sheet after being bent and pressed; Figure 5 As shown, the planar steel mesh sheet 1 composed of triangular lattice or rhombus lattice forms a tapered corrugated steel mesh sheet 2 after being bent and pressed.

[0049] In this embodiment, the double-sided two-way steel...

Embodiment 2

[0065] According to the requirements of the specific use for the bearing capacity of the ceramsite concrete slab, the double-sided two-way reinforced truss body can only include a flat steel mesh 1, and the flat steel mesh 1 is arranged above or below the corrugated steel mesh 2, and the two are welded or welded. connected by strapping, such as Figure 12 shown. Others are the same as in Example 1.

[0066] The bearing capacity of the ceramsite concrete slab in this embodiment is slightly lower than that of the ceramsite concrete slab in Embodiment 1, and is mostly used for interior wall panels.

Embodiment 3

[0068] For situations without load-bearing capacity requirements, such as internal wall partition panels, the double-sided two-way reinforced truss body may not use flat steel mesh 1, but only use a tapered corrugated steel mesh 2, or two triangular corrugated steel bars Mesh 2 superposition, such as Figure 13 shown.

[0069] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com