Segmented blade of a wind turbine

A technology for wind turbines and blades, applied in the field of segmented blades of wind turbines, can solve the problems of poor practicability of segmented solutions, reduced aerodynamic efficiency, complicated connection solutions, etc., achieves large operability space, saves production and material costs, Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

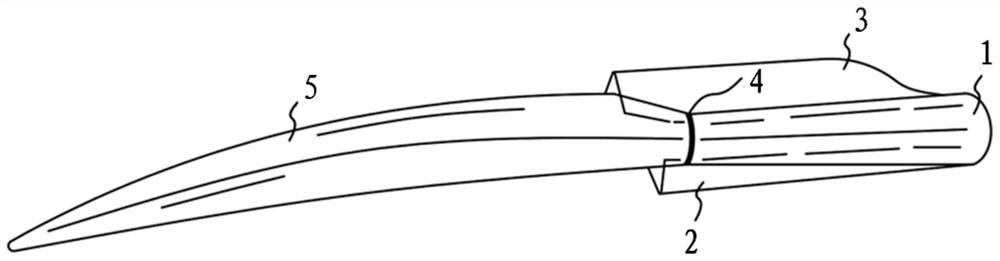

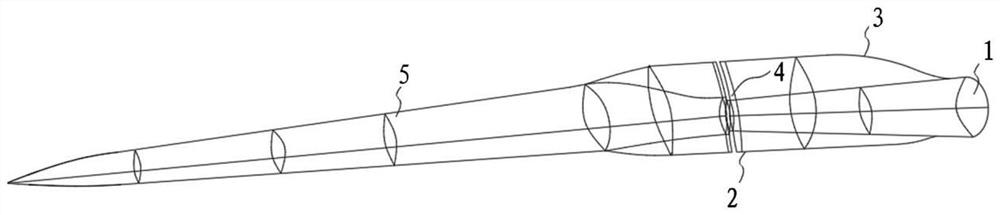

[0036] Such as figure 1 , figure 2 As shown, the present invention provides a segmented blade of a wind turbine, which includes a blade tip section 5, a blade root section 1, a connecting transition section 4, and a rectifying shell. Among them, the blade tip section 5 is connected to one end of the blade root section 1 through the connecting transition section 4, and the other end of the blade root section 1 is connected to the hub; Excellent aerodynamic shape.

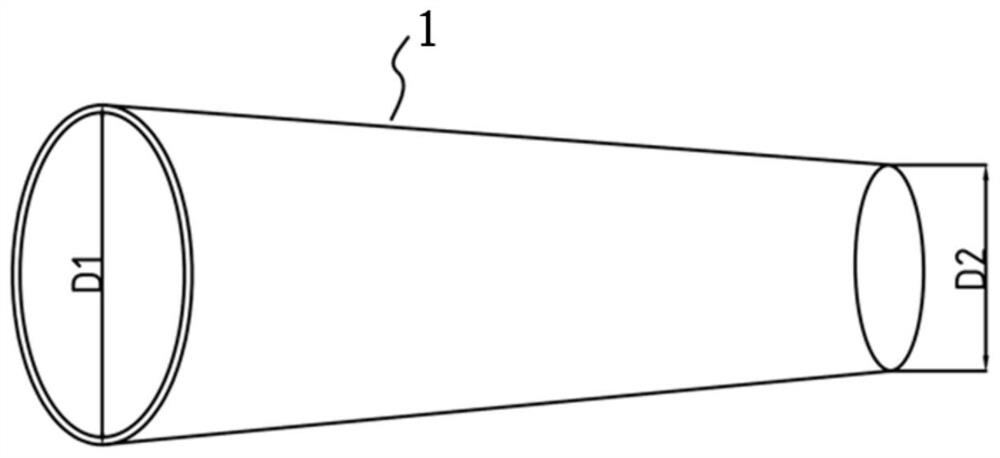

[0037] Such as image 3 As shown, the blade root section 1 is a structure of revolution, such as a cylinder or a cylinder approximately cylindrical, which may be hollow or solid. The caliber D2 at one end of the blade root section 1 may be different from the caliber D1 at the other end. In this example, D1>D2, such as figure 1 , figure 2 As shown, the end with a larger diameter is connected to the hub, and the end with a smaller diameter is connected to the blade root section 1 by connecting the transition sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com