Ultrasonic nano cooling device for computer motherboard

A cooling device, ultrasonic technology, applied in the direction of electrical digital data processing, instruments, calculations, etc., can solve the problems of increasing calorific value, affecting heat dissipation, easy hardening, etc., and achieve the effect of increasing the heat exchange surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

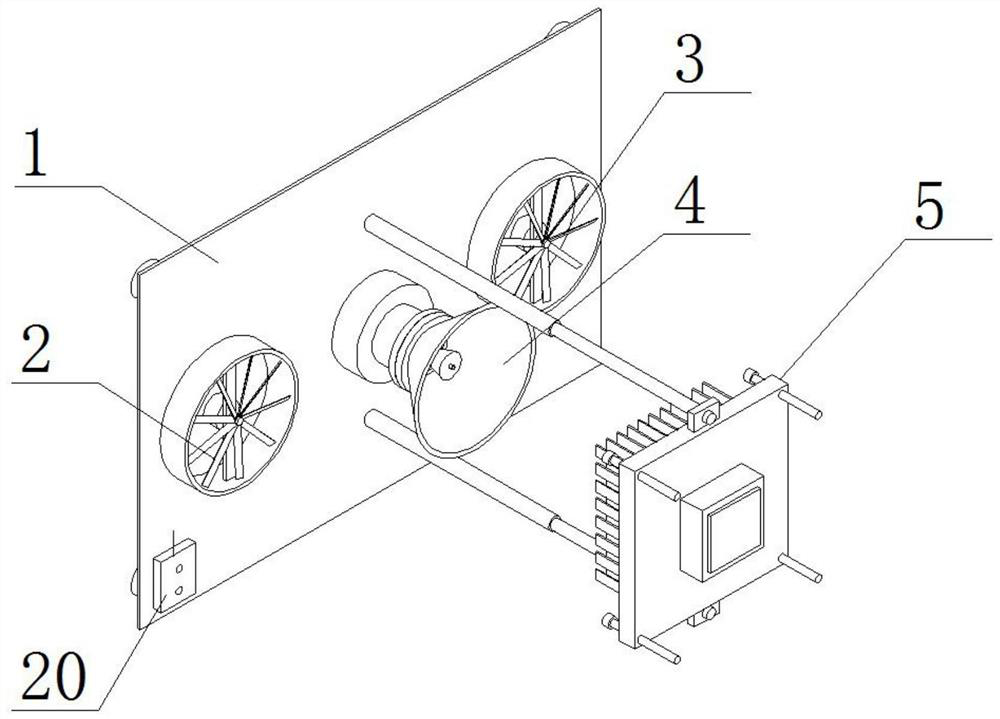

[0025] As a preferred embodiment of the present invention, magnetic pillars are uniformly arranged on one side wall of the bearing plate 1 .

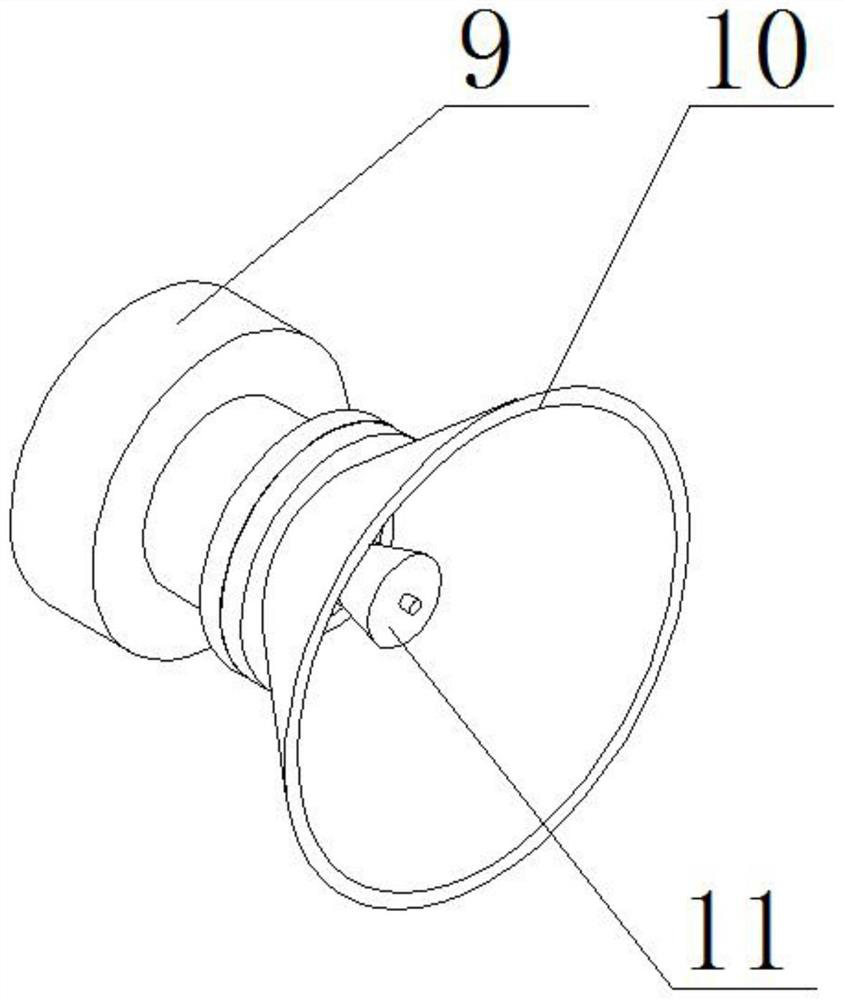

[0026] As a preferred embodiment of the present invention, the ultrasonic transmitter 9 is provided with an ultrasonic frequency modulation device.

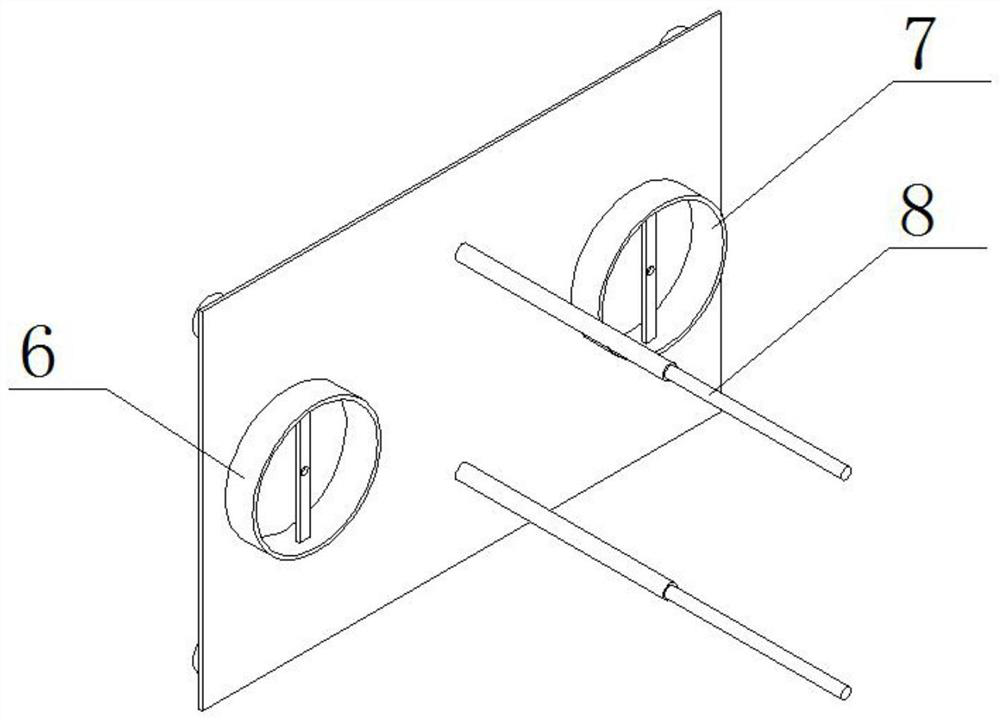

[0027] As a preferred embodiment of the present invention, a side wall of the aluminum alloy cooling plate 12 is uniformly provided with mounting holes, and bolts are sleeved in the mounting holes.

[0028] As a preferred embodiment of the present invention, the ultrasonic vibrator 11 corresponds to the aluminum alloy cooling plate 12 .

[0029] As a preferred embodiment of the present invention, both the inlet fan 2 and the exhaust fan 3 are provided with a motor and fan blades, and the fan blades are arranged at one end of the motor.

[0030] As a preferred embodiment of the present invention, the control buttons include a start button and a stop button, and the control buttons are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com