Low-temperature curing conductive silver paste with high conductivity and low silver content and preparation method thereof

A technology of conductive silver paste and high conductivity, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problem of high filling rate of commercial conductive silver paste and silver powder, and achieve excellent conductive network, Good electrical conductivity and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

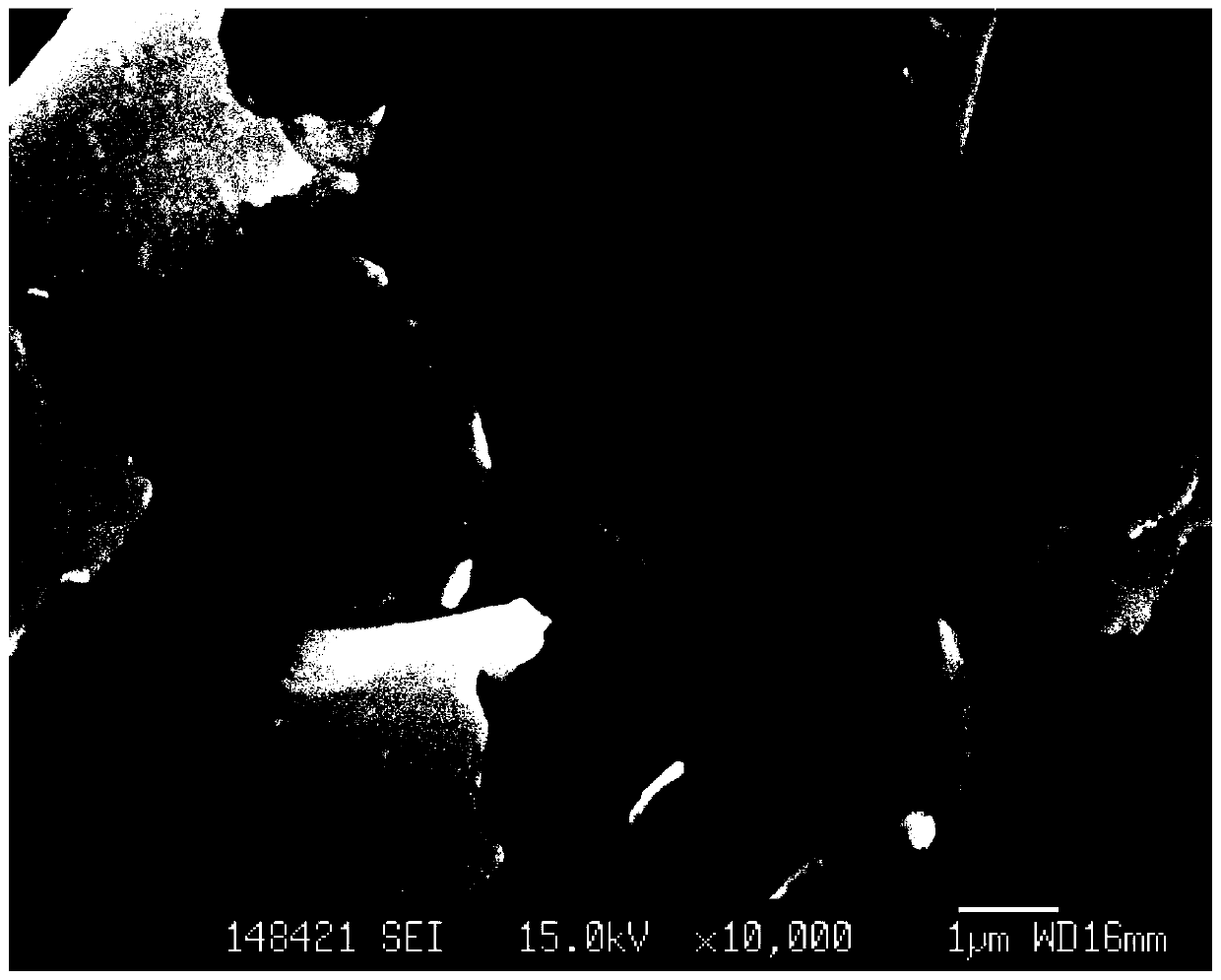

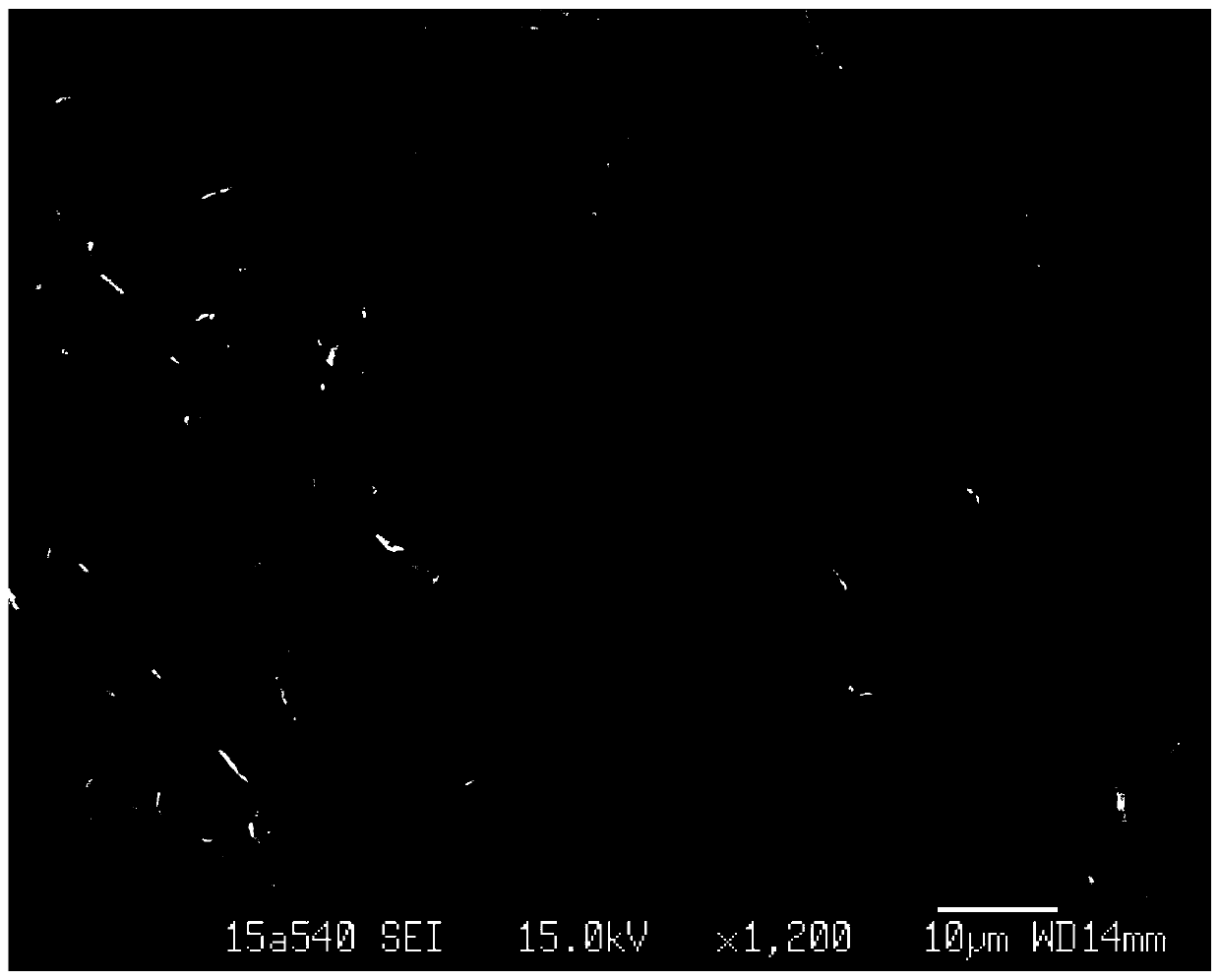

[0032] A low-temperature curing conductive silver paste with high conductivity and low silver content comprises the following components: self-made nano-flaky silver powder containing 25 wt% in the conductive silver paste (the silver powder is wet silver powder, and the silver powder contains 48 wt% of solids, and the dispersant is DBE), 9.6 wt% 71 resin, 62.9wt% DBE, PM solvent and 2.5 wt% malonic acid solution (20% mass fraction, PM solvent), the average particle size of silver powder is 4.6 μm, and the thickness is 50-60nm.

[0033] Preparation method: S1. Preparation of organic carrier: Dissolve 71 resin with a mass fraction of 30% in 70% PM, heat at a constant temperature at 70°C until completely dissolved, and cool for use;

[0034] S2. first add DBE solvent in container;

[0035] S3. Then add 2.5 wt% malonic acid (mass fraction is 20%, solvent is PM);

[0036] S4. After stirring for 1-3 min, add 25 wt% self-made nano-flaky silver powder, and fully stir for 15-30 min t...

Embodiment 2

[0041] A low-temperature curing conductive silver paste with high conductivity and low silver content, comprising the following components:

[0042] The conductive silver paste contains 22 wt% self-made flaky silver powder (the silver powder is wet silver powder, the silver powder contains 50 wt% solid silver powder, and the dispersant is DBE), 9.6 wt% of 71 resin, 66.2 wt% of DBE solvent and 2.2 wt% of Malonic acid solution (mass fraction is 20%, solvent is DBE), the average particle size of silver powder is 4.6 μm, and the thickness is 50-60 nm.

[0043] Preparation method: S1. Preparation of organic carrier: Dissolve 71 resin with a mass fraction of 25% in 75% DBE, heat at a constant temperature at 60°C until completely dissolved, and cool for later use;

[0044] S2. first add DBE solvent in container;

[0045] S3. Then add 2.2 wt% malonic acid (mass fraction is 20%, solvent is DBE);

[0046] S4. After stirring for 1-3 min, add 22 wt% self-made nano-flaky silver powder, a...

Embodiment 3

[0051] A low-temperature curing conductive silver paste with high conductivity and low silver content, comprising the following components:

[0052] The conductive silver paste contains 20 wt% self-made flake silver powder (the silver powder is wet silver powder, the silver powder contains 55 wt% solid silver powder, and the dispersant is DBE), 9.6 wt% of 71 resin, 68.4 wt% of cyclohexanone, PM and DBE Solvent and 2 wt% adipic acid solution (mass fraction is 20%, solvent is PM), the average particle size of silver powder is 4.6 μm, and the thickness is 50-60 nm.

[0053] Preparation method: S1. Preparation of organic carrier: dissolve 71 resin with a mass fraction of 30% in 70% PM, heat at a constant temperature at 60°C until completely dissolved, and cool for use;

[0054] S2. first add cyclohexanone in container;

[0055] S3. add the adipic acid of 2 wt% subsequently (mass fraction is 20%, solvent is PM);

[0056] S4. After stirring for 1-3 min, add 20 wt% self-made nano-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com