A kind of preparation method of extruded micro-expanded instant noodles

A technology of instant noodles and micro-expansion, which is applied in the field of pasta processing, can solve the problems that it is difficult to meet people's requirements for fast eating of instant noodles, affect the structure of raw materials, and the rehydration time of instant noodles is long, so as to facilitate protection, shorten the mixing time, The effect of retaining nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

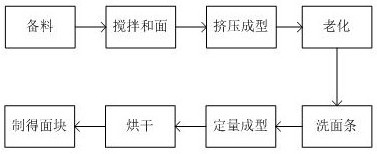

[0034] see figure 1 , a preparation method of extruded micro-expanded instant noodles, comprising the following steps:

[0035] (1) Preparation of raw materials: Weigh the following raw materials according to parts by weight: 75 parts of high-gluten refined flour, 6 parts of rice flour, 3 parts of corn starch, 3 parts of tapioca starch, 2.5 parts of wheat starch, 0.3 parts of baking soda, 0.005 parts of compound phosphate part, 0.003 part of guar gum, wherein the components of the composite phosphate include sodium tripolyphosphate, sodium hexametaphosphate, sodium pyrophosphate, wherein the weight ratio of sodium tripolyphosphate, sodium hexametaphosphate, and sodium pyrophosphate is 2:1:1.

[0036] (2) Stir and knead the dough: add edible salt and water to all the raw materials in step (1), mix and stir for 4 minutes to obtain a dough, wherein the weight of the edible salt added is 1% of all the raw materials in the step (1), and the weight of water added is 38% of all raw...

Embodiment 2

[0046] A preparation method of extruded micro-expanded instant noodles, comprising the following steps:

[0047] (1) Prepare raw materials: Weigh the following raw materials according to parts by weight: 95 parts of high-gluten refined flour, 12 parts of rice flour, 4 parts of corn starch, 4 parts of tapioca starch, 3.5 parts of wheat starch, 0.5 parts of baking soda, 0.015 parts of compound phosphate part, 0.006 part of guar gum, wherein the components of the composite phosphate include sodium tripolyphosphate, sodium hexametaphosphate, and sodium pyrophosphate, wherein the proportion by weight of sodium tripolyphosphate, sodium hexametaphosphate, and sodium pyrophosphate is: 2:1:1.

[0048](2) Stir and knead the dough: add edible salt and water to all the raw materials in step (1) and mix and stir for 6 minutes to obtain a dough, wherein the weight of the edible salt added is 3% of all the raw materials in the step (1), and the weight of the water added is 40% of all raw ma...

Embodiment 3

[0058] A preparation method of extruded micro-expanded instant noodles, comprising the following steps:

[0059] (1) Prepare raw materials: Weigh the following raw materials according to parts by weight: 80 parts of high-gluten refined flour, 10 parts of rice flour, 3.5 parts of corn starch, 3.3 parts of tapioca starch, 2 parts of wheat starch, 0.4 parts of baking soda, 0.001 parts of compound phosphate part, 0.004 part of guar gum, wherein the components of the compound phosphate include sodium tripolyphosphate, sodium hexametaphosphate, sodium pyrophosphate, wherein the weight ratio of sodium tripolyphosphate, sodium hexametaphosphate, and sodium pyrophosphate is 2:1:1.

[0060] (2) Stir and knead the dough: All the raw materials in step (1) are added with edible salt and water, mixed and stirred for 5 minutes to obtain a dough, wherein the weight of the edible salt added is 2% of all the raw materials in the step (1), and the weight of the water added is 38.5% of all raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com