Japanese premna herb jelly and preparation method thereof

A technology for rotten fruit and jelly, which is applied in the field of rotten jelly and its preparation, can solve the problems of poor molding state, difficult dehydration, heavy quality and the like, and achieves the effects of easy portability and storage, low cost and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of bean curd jelly comprises the following steps:

[0044] a. Mix pulping with bean curd leaves and water in a weight ratio of 1:8-12, after filtering, obtain filtrate A;

[0045] b. Mix the filtrate A and the coagulant obtained in step a to obtain the mixed solution B; wherein, the preparation method of the coagulant is: mix the salt mixture and water in a weight ratio of 1:8-12; the salt The amount of the mixture is taken by weighing 20:0.1-2 according to the weight ratio of the rot leaves and the salt mixture; the salt mixture is prepared by mixing carbonate and phosphate in a weight ratio of 1:4-6;

[0046] c. Leave the mixed solution B for 1-3 hours to obtain the rotten maid jelly.

[0047] The pulping method can be as follows: mix the rotten maidservant leaves with water and then squeeze the juice. After the juice from the leaves is squeezed out, the clear water will turn into a faint green viscous liquid. Filtration can use clean gauze to...

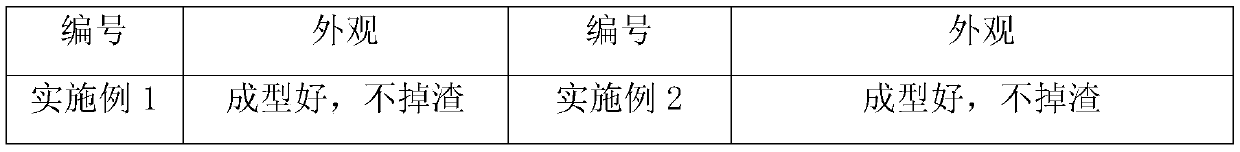

Embodiment 1

[0071] Step 1. Juicing

[0072] Mix 20g of washed rotten leaves with 200g of pure water and squeeze out the juice. After the juice from the leaves is squeezed out, the water will turn into a faint green viscous liquid. Use clean gauze to filter out the dregs in the liquid to obtain samples a.

[0073] Step 2, prepare coagulant

[0074] The weight ratio of carbonate and phosphate is 1:5 to take the salt mixture, and the total mass of the salt mixture is 0.1g, wherein the carbonate is mixed with potassium carbonate and calcium carbonate in a weight ratio of 6:1; for potassium phosphate. Mix the weighed salt mixture with deionized water at a ratio of 1:10, stir at room temperature until completely dissolved, and obtain a coagulant.

[0075] Step 3. Add coagulant: blend the coagulant produced in step 2 into sample A, pour the coagulant while stirring in one direction. Note that the two are fully integrated, but the stirring time should not be too long.

[0076] Step 4, formin...

Embodiment 2

[0081] Compared with Example 1, the difference between Example 2 and Example 1 is that the addition amount of the salt mixture in step 2 becomes 0.5 g, and the ratio of the salt substance remains unchanged; the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com