Dust removal method and device for dust-containing gas

A gas and filter layer technology, applied in the environmental protection field of air pollution control, can solve the problems of easy aging of filter bags, difficult adaptation of cloth bags, clogging in the filtration process, etc. stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

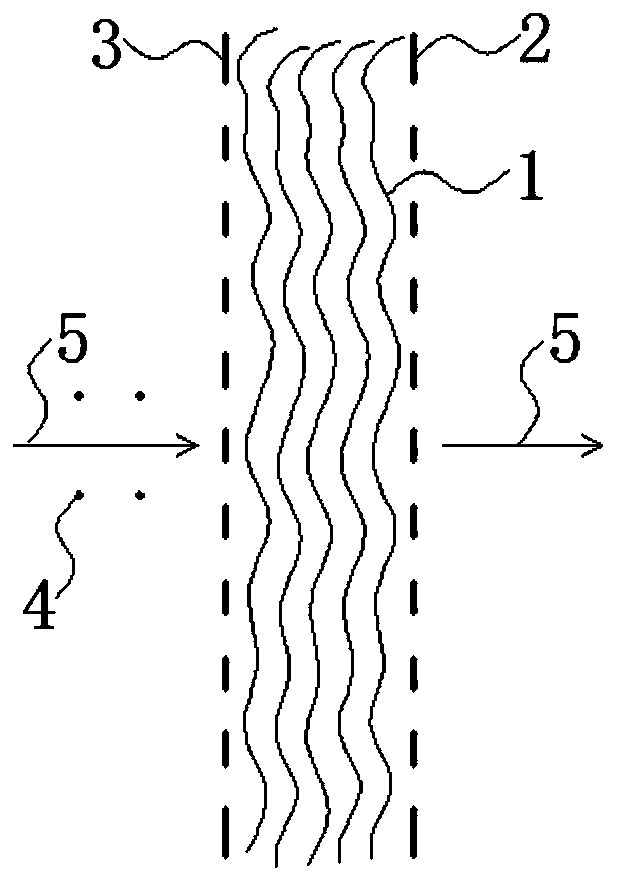

Method used

Image

Examples

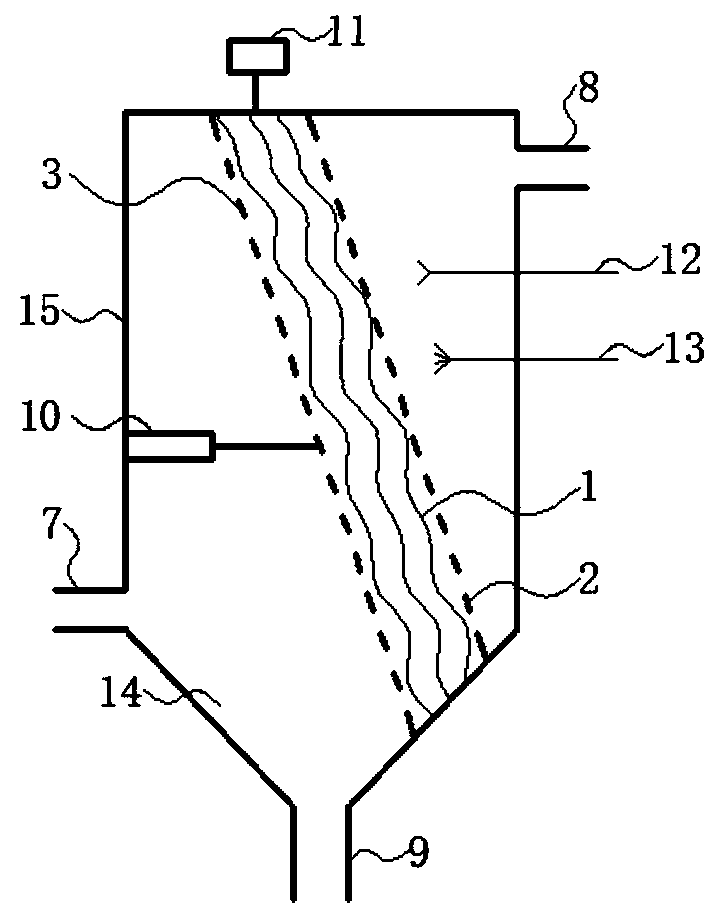

Embodiment 1

[0028] This embodiment is an embodiment of dedusting the high-temperature, wet and dust-laden gas with closed vaporization and coke quenching. Such as image 3As shown, the 300°C gas 5 (water vapor) containing dust particles 4 (coke powder particles) produced by spraying water on the red coke enters the dust removal device through the dust-containing gas inlet 7 on the dust removal device casing 15, and passes through the pressure. The coke powder is trapped in the tight filter layer 1, and the water vapor is discharged from the dust collector from the purified gas outlet 8 after passing through the filter layer. The filter layer is installed obliquely in the dust removal device, the dust-laden gas enters the lower part, and the purified gas is discharged from the upper part of the filter layer. The fixed porous pressing surface 2 is arranged on the side of the purified gas (the upper part of the filter layer), and the movable porous pressing surface 3 is arranged on the side...

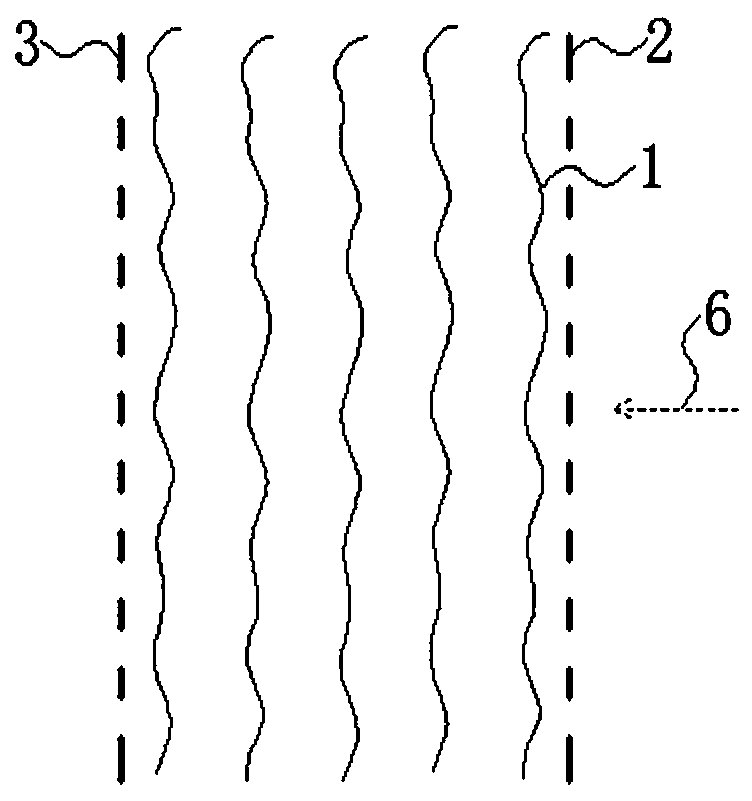

Embodiment 2

[0032] This embodiment is an embodiment of using a filter layer composed of multi-layer wire mesh to remove dust from the dusty flue gas of a steelmaking furnace. The process is basically the same as in Example 1, except that the filter layer is composed of multi-layer wire mesh, the wire mesh is 200-mesh stainless steel mesh, and the outer side of the wire mesh is pressure-bearing with a punching plate. The high-temperature dust-laden flue gas at about 300 °C passes through the filter layer composed of stainless steel mesh to remove dust particles, and then the flue gas enters the heat recovery system. Dust removal adopts the combined form of water flushing with surfactant and air back blowing.

Embodiment 3

[0034] This embodiment is basically the same as Embodiment 1, except that the dust removal temperature for starch drying gas is 90±10°C, polyester filament is used as the filter material, and the pressing surface adopts a combined structure of outer punching plate and inner screen. Dust removal adopts the combination of gas back blowing mechanism 12 and vibration mechanism 11. After the starch drying gas is dedusted, it reaches the discharge standard and can run smoothly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com