A kind of preparation method of porous polyquaternium salt gel adsorbent

A polyquaternary ammonium salt and adsorbent technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of printing and dyeing wastewater adsorption and decolorization, achieve strong adsorption and capture capabilities, and improve reaction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

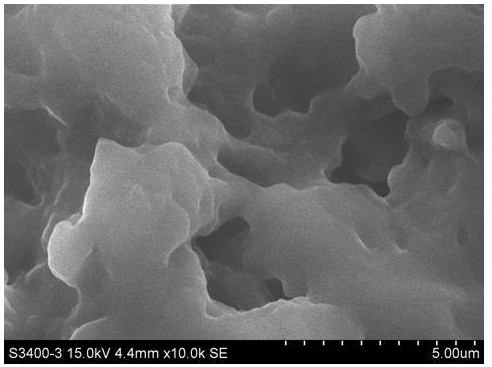

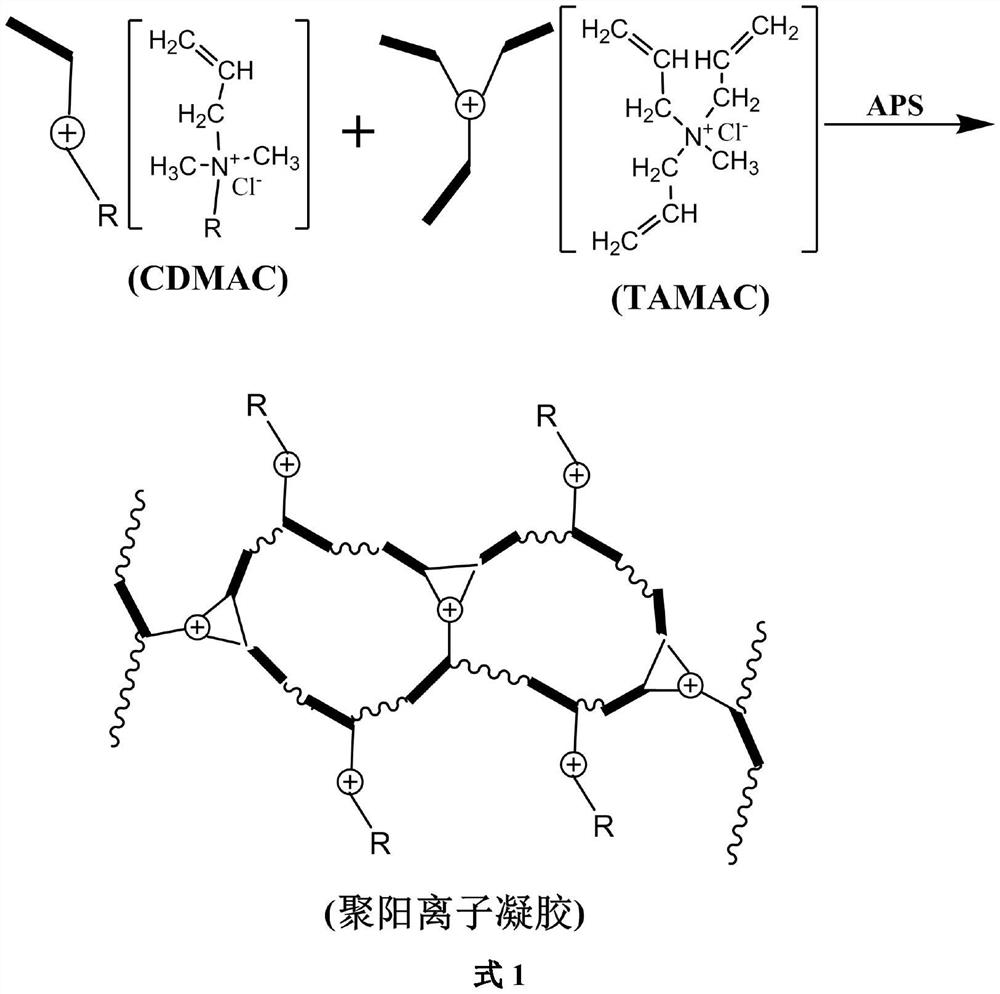

[0025] Step 1: Take the measured cross-linking quaternary ammonium salt monomer TAMAC and the large molecular volume quaternary ammonium salt monomer CDMAAC [the molar ratio of the two monomers is n (TAMAC) / n (CDMAC) =95 / 5] join in the reactor that reflux condensing device is housed and be made into the reaction solution that initial monomer solution mass fraction is 55%;

[0026] Step 2: Weigh the initiator ammonium persulfate APS accounting for 1% of the total monomer mass (the sum of TAMAC and CDMAC mass), add it to the reaction solution, stir and mix evenly;

[0027] Step 3: First pass through the three-way ventilation system, with inert protective gas N 2 Replace the air in the reaction system, and then add N 2 The introduction tube is inserted into the reaction mixture for bubbling, and under mechanical stirring, the temperature is raised to 50°C for bubbling cross-linking copolymerization reaction for 0.5h, and the reaction material is viscous and flowing;

[0028]...

Embodiment 2

[0033] Step 1: Take the measured cross-linking quaternary ammonium salt monomer TAMAC and the large molecular volume quaternary ammonium salt monomer CDMAAC [the molar ratio of the two monomers is n (TAMAC) / n (CDMAC) =50 / 50] join in the reactor that reflux condensing device is housed and be made into the reaction solution that initial monomer solution mass fraction is 60%;

[0034] Step: 2: take by weighing the initiator ammonium persulfate APS accounting for 2% of the total monomer mass (TAMAC and CDMAC mass sum), join in the reaction solution, stir and mix;

[0035] Step 3: First pass through the three-way ventilation system, with inert protective gas N 2 Replace the air in the reaction system, and then add N 2 The introduction tube is inserted into the reaction mixture for bubbling, and under mechanical stirring, the temperature is raised to 50-55°C for bubbling cross-linking copolymerization reaction for 1.0h, and the reaction material is viscous and flowing;

[0036] ...

Embodiment 3

[0041] Step 1: Take the measured cross-linking quaternary ammonium salt monomer TAMAC and the large molecular volume quaternary ammonium salt monomer CDMAC [the molar ratio of the two monomers is n(TAMAC) / n(CDMAC)=5 / 95] and join in In the reactor equipped with reflux condensing device and be made into the reaction solution that initial monomer solution mass fraction is 65%;

[0042] Step 2: Weigh the initiator ammonium persulfate APS accounting for 1-3% of the total monomer mass (the sum of TAMAC and CDMAC mass), add it to the reaction solution, stir and mix evenly;

[0043] Step 3: First pass through the three-way ventilation system, with inert protective gas N 2 Replace the air in the reaction system, and then add N 2 The introduction tube is inserted into the reaction mixture for bubbling, and under mechanical stirring, the temperature is raised to 55°C for bubbling cross-linking copolymerization reaction for 1.0h, and the reaction material is viscous and flowing;

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com