Method for preparing monocalcium chlorophosphate and magnesium hydroxide from high-magnesium-content phosphate tailings

A technology of high magnesium phosphorus tailings and calcium chlorophosphate is applied in the field of waste resource utilization, which can solve the problems of low added value of products and low utilization rate of phosphorus tailings, so as to reduce the cost of resource utilization and improve resources. The effect of simplifying the utilization rate and resource utilization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

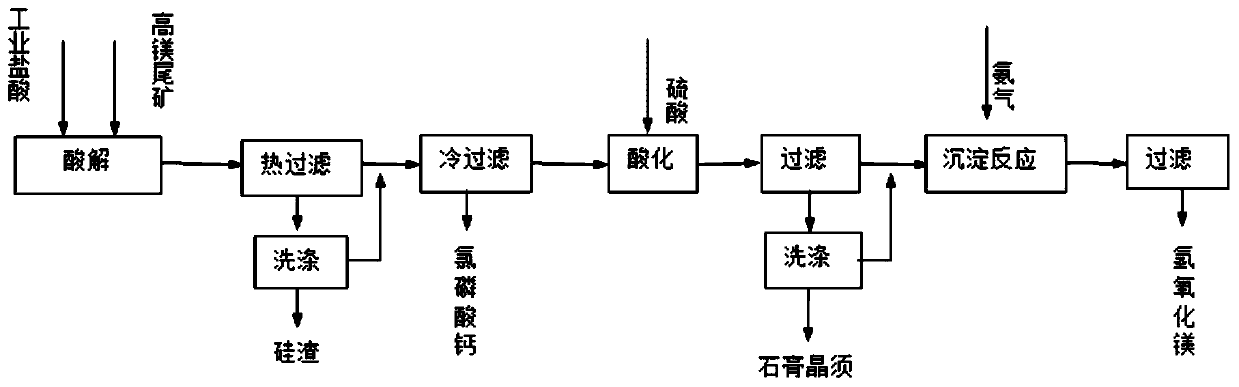

[0027] combine figure 1 As shown, the method for preparing calcium chlorophosphate and magnesium hydroxide by utilizing high-magnesium phosphorus tailings of the present embodiment specifically comprises the following steps:

[0028] 1) Measure 490mL of industrial hydrochloric acid with a mass fraction of 33.3% (10.41mol / L) in a clean three-necked flask, weigh 261.8g of high-magnesium phosphorus tailings powder, and gradually add high-magnesium phosphorus tailings to the three-necked flask In the flask, after adding the high-magnesium phosphorus tailings, open the condensed water, start stirring, reflux at 50°C for 30 minutes, and carry out the acidolysis reaction. Silicon slag, wherein, the silicon slag is washed three times with 100mL distilled water, and the first washing solution is mixed with the acid solution A;

[0029] 2) Pour the acid solution A into a dry beaker, place it in an ice bath at -6°C, and let it stand for 14 hours to completely precipitate the white calci...

Embodiment 2

[0033] combine figure 1 As shown, the method for preparing calcium chlorophosphate and magnesium hydroxide by utilizing high-magnesium phosphorus tailings of the present embodiment specifically comprises the following steps:

[0034] 1) Measure 500mL of industrial hydrochloric acid with a mass fraction of 32.8% (10.37mol / L) in a clean three-necked flask, weigh 261.8g of high-magnesium phosphorus tailings powder, and gradually add high-magnesium phosphorus tailings to the three-necked flask In the flask, after the addition of high-magnesium phosphorus tailings is completed, open the condensed water, start stirring, and reflux at 30°C for 40 minutes to carry out acidolysis reaction. Silicon slag, wherein, the silicon slag is washed three times with 100mL distilled water, and the first washing solution is mixed with the acid solution A;

[0035] 2) Pour the acid solution A into a dry beaker, place it in an ice bath at -9°C, and let it stand for 10 hours to completely precipitate...

Embodiment 3

[0039] combine figure 1 As shown, the method for preparing calcium chlorophosphate and magnesium hydroxide by utilizing high-magnesium phosphorus tailings of the present embodiment specifically comprises the following steps:

[0040] 1) Measure 520mL of industrial hydrochloric acid with a mass fraction of 34% (10.06mol / L) in a clean three-necked flask, weigh 261.8g of high-magnesium phosphorus tailings powder, and gradually add high-magnesium phosphorus tailings to the three-necked flask In the flask, after the addition of high-magnesium phosphorus tailings is completed, open the condensed water, start stirring, and reflux at 45°C for 20 minutes to carry out acidolysis reaction. Silicon slag, wherein, the silicon slag is washed three times with 100mL distilled water, and the first washing solution is mixed with the acid solution A;

[0041] 2) Pour the acid solution A into a dry beaker, place it in an ice bath at -5°C, and let it stand for 18 hours to completely precipitate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com