A kind of polyamide-amine hyperbranched polymer and its preparation method and application

A technology of hyperbranched polymers and polyamides, which is applied in the dehydration/demulsification of hydrocarbon oil and the petroleum industry, etc. It can solve the problems that the demulsification efficiency needs to be improved, and achieve high demulsification efficiency, fast demulsification speed and low solvent consumption. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

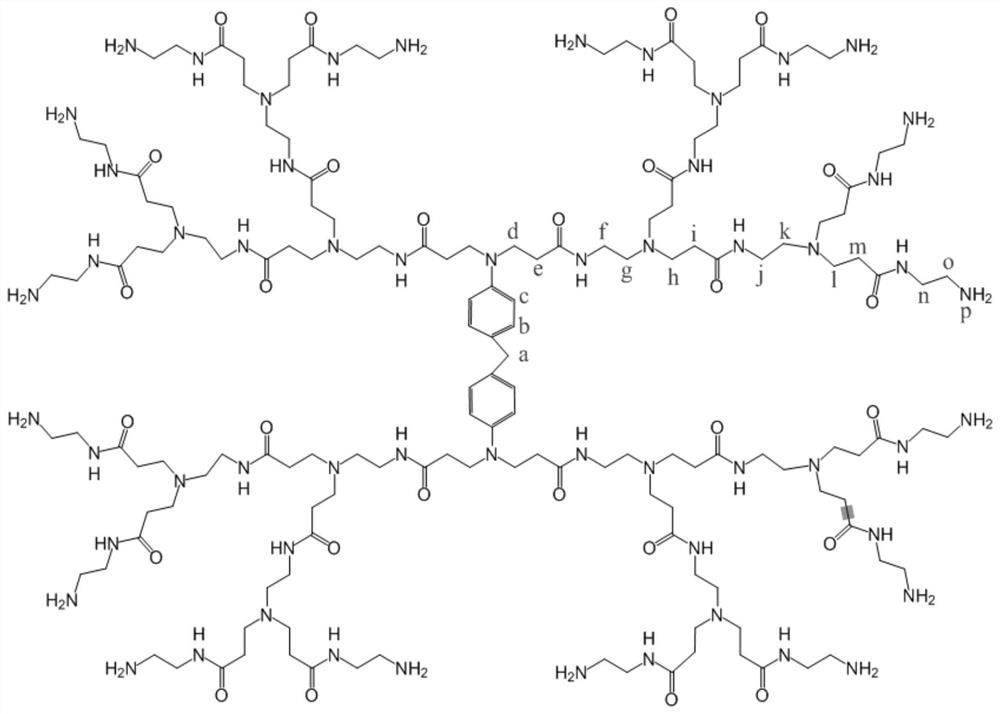

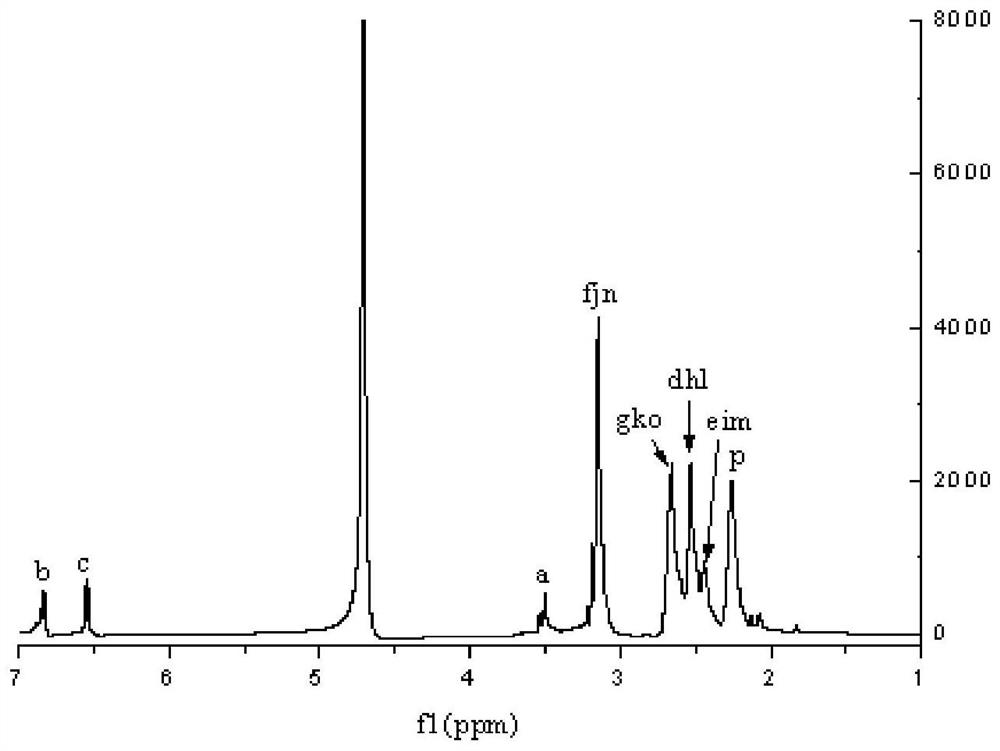

[0033] Adopt the following method to prepare polyamide-amine hyperbranched polymer in the present embodiment, mainly comprise the following steps:

[0034] S1: 5.34g (0.02mol) of 4,4'-diaminodiphenylmethane was dissolved in 30ml of methanol, then 6.88g (0.08mol) of methyl acrylate was added dropwise thereto, and the mixture was kept at room temperature (25°C) The reaction was stirred at a rate of 300r / min for 24h.

[0035] S2: Add 33.6g (0.56mol) of ethylenediamine and 41.28g (0.48mol) of methyl acrylate into S1, continue the reaction at room temperature for 24h, and then remove the solvent methanol by reducing pressure.

[0036] S3: The mixed solution was reacted under reduced pressure at 60°C for 1h, 80°C for 1h, 100°C for 2h, 120°C for 2h, and 140°C for 2h, cooled naturally to room temperature, precipitated with ether, and dried in vacuo to obtain a bright yellow product.

[0037] Using 4,4'-diaminodiphenylmethane in this example as the core, controlling the stoichiometric...

Embodiment 2

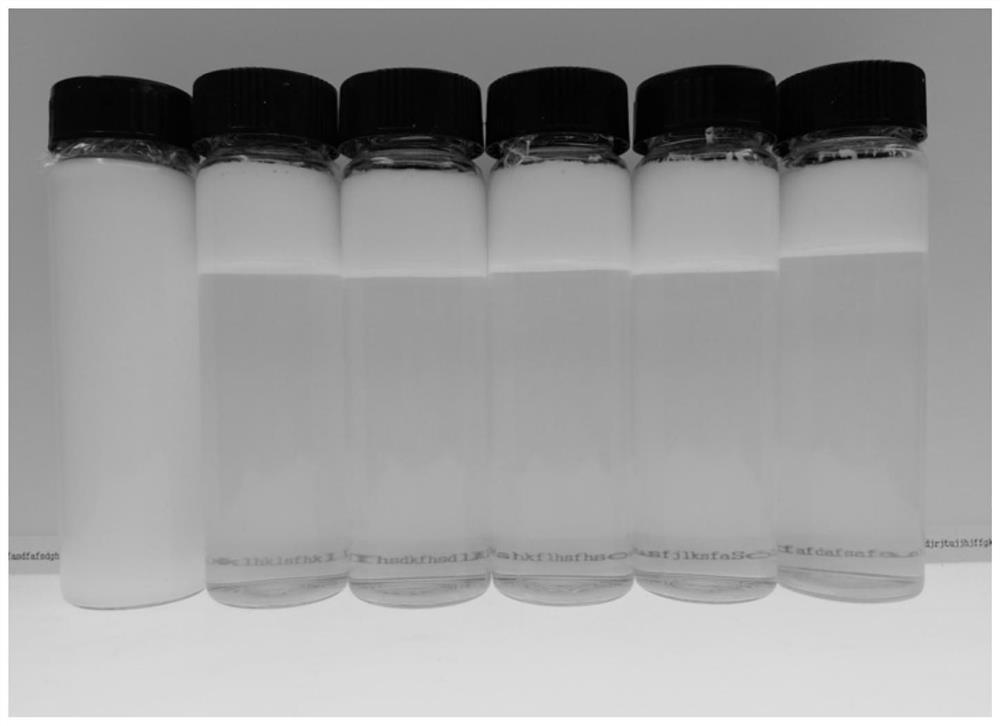

[0042] 2mL polyamide-amine hyperbranched polymer concentration is the demulsifier aqueous solution of 1000mg / L and is added in 38mL diesel oil / water emulsion, and polyamide-amine hyperbranched polymer concentration is 50mg / L (50ppm) in the emulsion, passes Vibrate quickly to make it evenly mixed, and then stand at 60° C. for 30 minutes. The light transmittance of the water phase was determined to be 82.7%, and the demulsification efficiency was 95.4%. After standing at 60° C. for 60 minutes, the light transmittance of the aqueous phase was determined to be 84%, and the demulsification efficiency was 95.9%. After standing at 60° C. for 120 minutes, the measured light transmittance of the water phase was 87.1%, and the demulsification efficiency was 99.5%.

Embodiment 3

[0044] 2mL polyamide-amine hyperbranched polymer concentration is the demulsifier aqueous solution of 1000mg / L and is added in 38mL diesel oil / water emulsion, and polyamide-amine hyperbranched polymer concentration is 50mg / L (50ppm) in the emulsion, passes Vibrate quickly to make it evenly mixed, and then stand still at 50° C. for 60 minutes. The light transmittance of the water phase is determined to be 80.1%, and the demulsification efficiency is 93.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| demulsification efficiency | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| demulsification efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com