A kind of method for preparing hard PVC with nano-calcium carbonate

A nano-calcium carbonate, hard technology, applied in chemical instruments and methods, dyed high molecular organic compound treatment, dyed low molecular organic compound treatment and other directions, can solve the problems of unhardened PVC hue research, achieve good economic benefits and Social benefits, low moisture absorption, simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

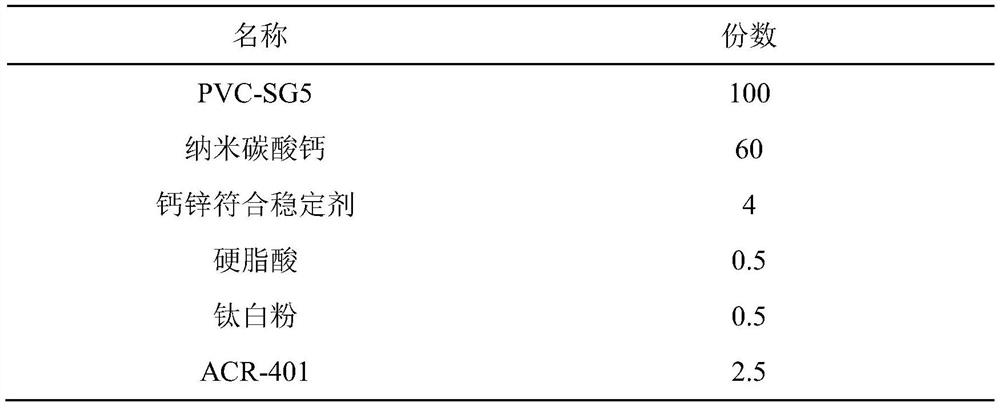

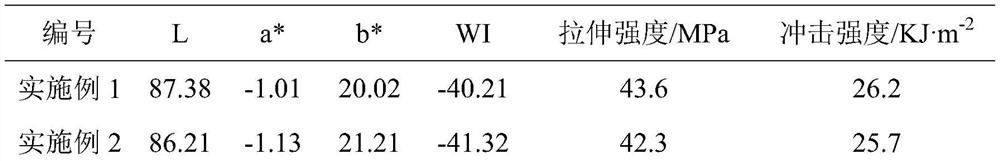

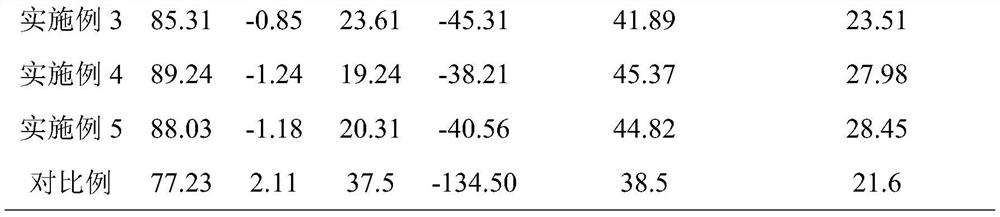

Embodiment 1

[0027] A method for preparing nano-calcium carbonate for rigid PVC, comprising the steps of:

[0028] (1) Adjust the specific gravity of the refined milk of lime to 1.065, then introduce it into the bubbling carbonation reactor, adjust the temperature of the milk of lime to 25°C, and introduce CO 2 The mixed gas with a concentration of 33% is subjected to carbonation reaction to pH = 7.0 to obtain a nano-calcium carbonate suspension;

[0029] (2) The nano-calcium carbonate suspension is heated to 80 ° C, and the surface compounded by carboxylated polyethylene wax, epoxy sunflower oil and xylitol is added in an amount of 2.5% based on the dry basis of calcium carbonate. Treatment agent, the mass percentages of carboxylated polyethylene wax, epoxy sunflower oil and xylitol in the surfactant are respectively 35%, 60%, and 5%, and after stirring for 40min, the surface modification is completed;

[0030] (3) The nano-calcium carbonate suspension that has completed the surface modi...

Embodiment 2

[0032] A method for preparing nano-calcium carbonate for rigid PVC, comprising the steps of:

[0033] (1) Adjust the specific gravity of the refined milk of lime to 1.070, then introduce it into the bubbling carbonation reactor, adjust the temperature of the milk of lime to 28°C, and introduce CO 2 The mixed gas with a concentration of 33% is subjected to carbonation reaction to pH = 7.0 to obtain a nano-calcium carbonate suspension;

[0034] (2) The nano-calcium carbonate suspension is heated to 75 ° C, and the surface compounded by carboxylated polyethylene wax, epoxy sunflower oil and xylitol is added in an amount of 3.0% based on the dry basis of calcium carbonate. Treatment agent, the mass percentages of carboxylated polyethylene wax, epoxy sunflower oil and xylitol in the surfactant are respectively 40%, 55%, and 5%, and after stirring for 40min, the surface modification is completed;

[0035] (3) The nano-calcium carbonate suspension that has completed the surface modi...

Embodiment 3

[0037] A method for preparing nano-calcium carbonate for rigid PVC, comprising the steps of:

[0038] (3) Adjust the specific gravity of the refined milk of lime to 1.060, then introduce it into the bubbling carbonation reactor, adjust the temperature of the milk of lime to 30°C, and introduce CO 2 The mixed gas with a concentration of 33% is subjected to carbonation reaction to pH = 7.0 to obtain a nano-calcium carbonate suspension;

[0039] (4) The nano-calcium carbonate suspension is heated to 85 ° C, and the surface compounded by carboxylated polyethylene wax, epoxy sunflower oil and xylitol is added in an amount of 2.0% based on the dry basis of calcium carbonate. Treatment agent, the mass percentages of carboxylated polyethylene wax, epoxy sunflower oil and xylitol in the surfactant are respectively 35%, 60%, and 5%, and after stirring for 45min, the surface modification is completed;

[0040] (3) The nano-calcium carbonate suspension that has completed the surface modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap