Hot-adhesion-release polyacrylic acid pressure-sensitive adhesive and preparation method thereof

A technology of polyacrylic pressure-sensitive adhesives and pressure-sensitive adhesives, which is applied in the field of pressure-sensitive adhesives and can solve problems such as difficult to tear off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

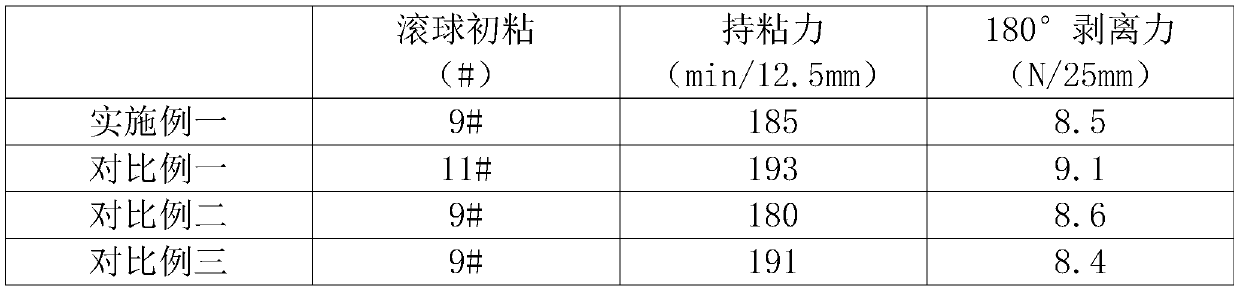

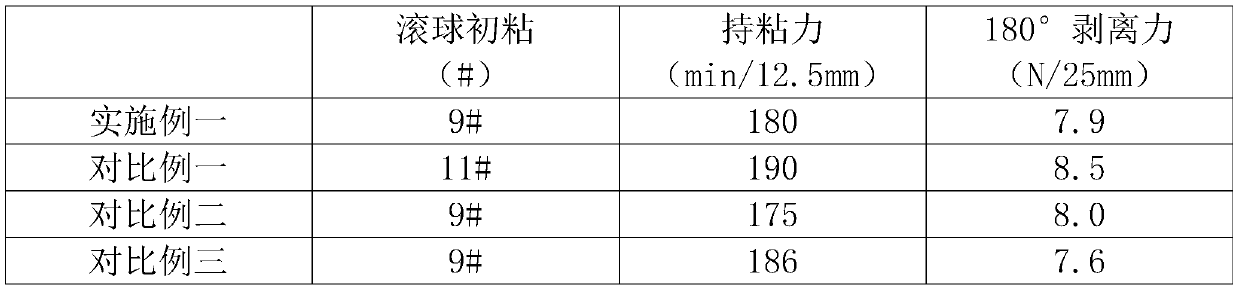

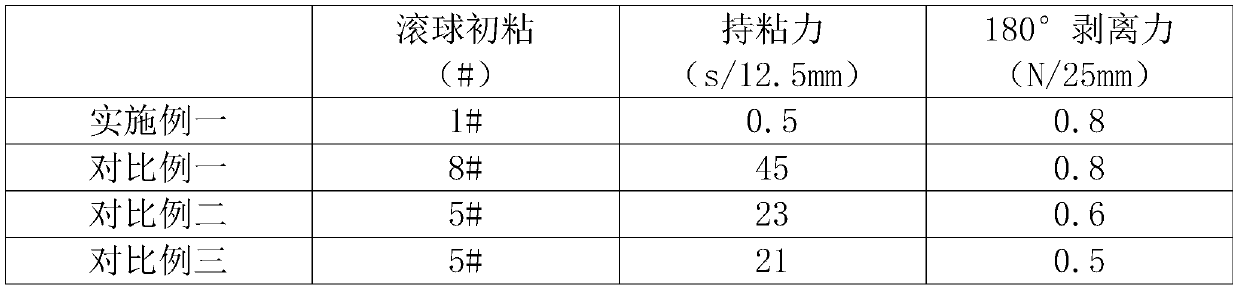

Examples

Embodiment 1

[0036] A thermally debonded polyacrylic pressure sensitive adhesive,

[0037] Comprising the following parts by weight:

[0038] Isooctyl acrylate: 50 parts

[0039] Methyl acrylate: 30 parts

[0040] Hydroxyethyl acrylate: 5 parts

[0041] Mixed solvent: 15 parts

[0042] Thiol compounds: 1 part

[0043] S-1-propenyl (Z)-2-propenylthiosulfite: 0.3 parts

[0044] Benzoyl peroxide: 0.5 parts

[0045] Mixed wax: 0.3 parts

[0046] The mixed wax is a mixture of polyethylene wax, microcrystalline wax and montan wax.

[0047] The mixed wax is a mixture of polyethylene wax, microcrystalline wax and montan wax with a mass ratio of 4:2:1.

[0048] Described mixed solvent is the mixture of toluene and ethyl acetate.

[0049] The mixed solvent is a mixture of toluene and ethyl acetate with a mass ratio of 3:1.

[0050] The mercaptan compound is n-dodecanethiol.

[0051] step one:

[0052] Mix isooctyl acrylate, methyl acrylate, hydroxyethyl acrylate and initiator benzoyl per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com