Multi-section carbon ring labyrinth sealing structure of supercritical carbon dioxide turboexpander

A technology of turbo expander and carbon ring seal, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of large gas leakage, time-consuming and labor-consuming sealing effect, and affect production efficiency, so as to reduce gas The effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

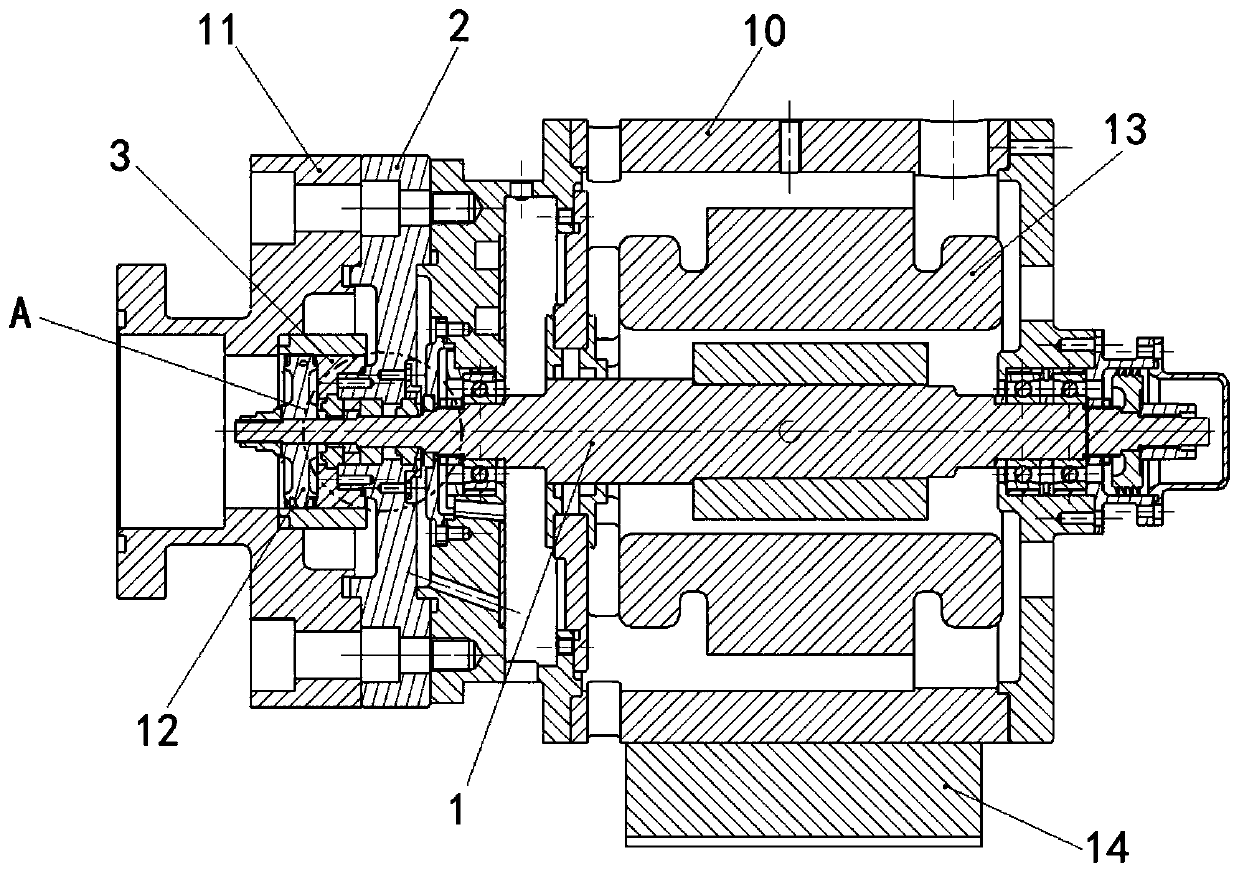

[0024] The structure of the supercritical carbon dioxide turboexpander involved in the present invention is as attached figure 1 As shown, including the turbine part and the motor part. The turbine part includes an intake volute 11 , a nozzle ring seat 2 , a nozzle 3 and an impeller 12 . The motor part includes an expander body 10 , a motor coil winding 13 , a main shaft 1 and a frame 14 . One side of the nozzle ring seat 2 is connected to the intake volute 11 to form an air intake cavity, and the other side is connected to the expander body 10; the nozzle 3 is fixed on the nozzle ring seat 2 by bolts One side connected to the intake volute 11; the impeller 12 is arranged axially with the nozzle 3, rotates under the action of the nozzle 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com