Energy-saving and reliable scraper hydraulic system

A hydraulic system and scraper technology, applied in the field of hydraulic systems, can solve the problems of low energy efficiency utilization rate of hydraulic pumps, high failure rate of oil cylinders, short service life, etc., to save low-pressure pilot pumps, reduce failure rates, and improve service life and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

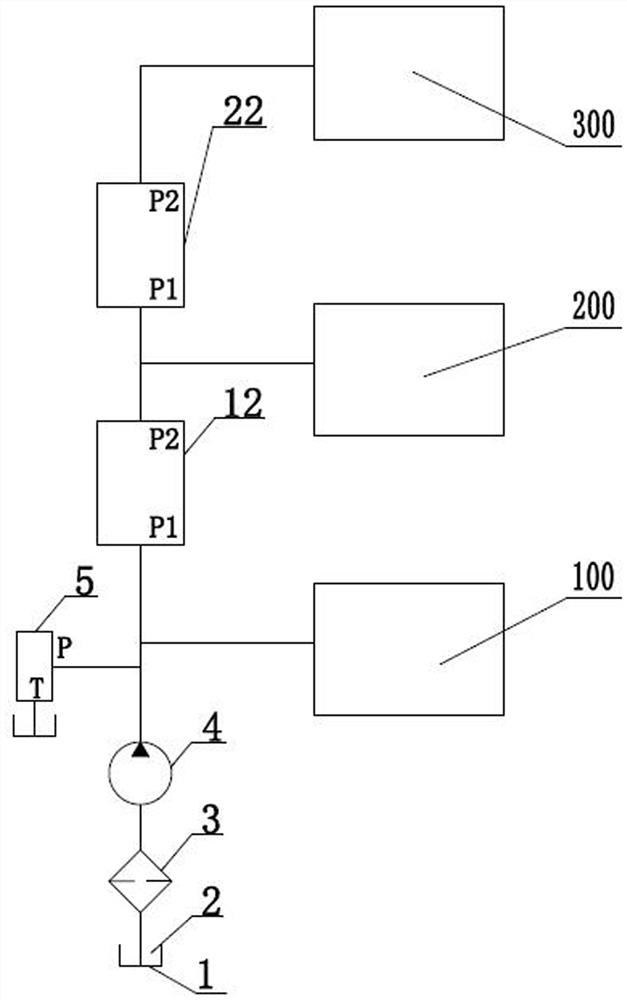

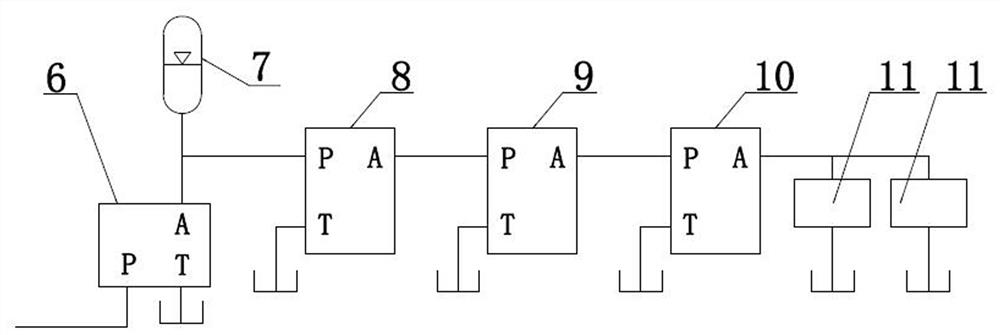

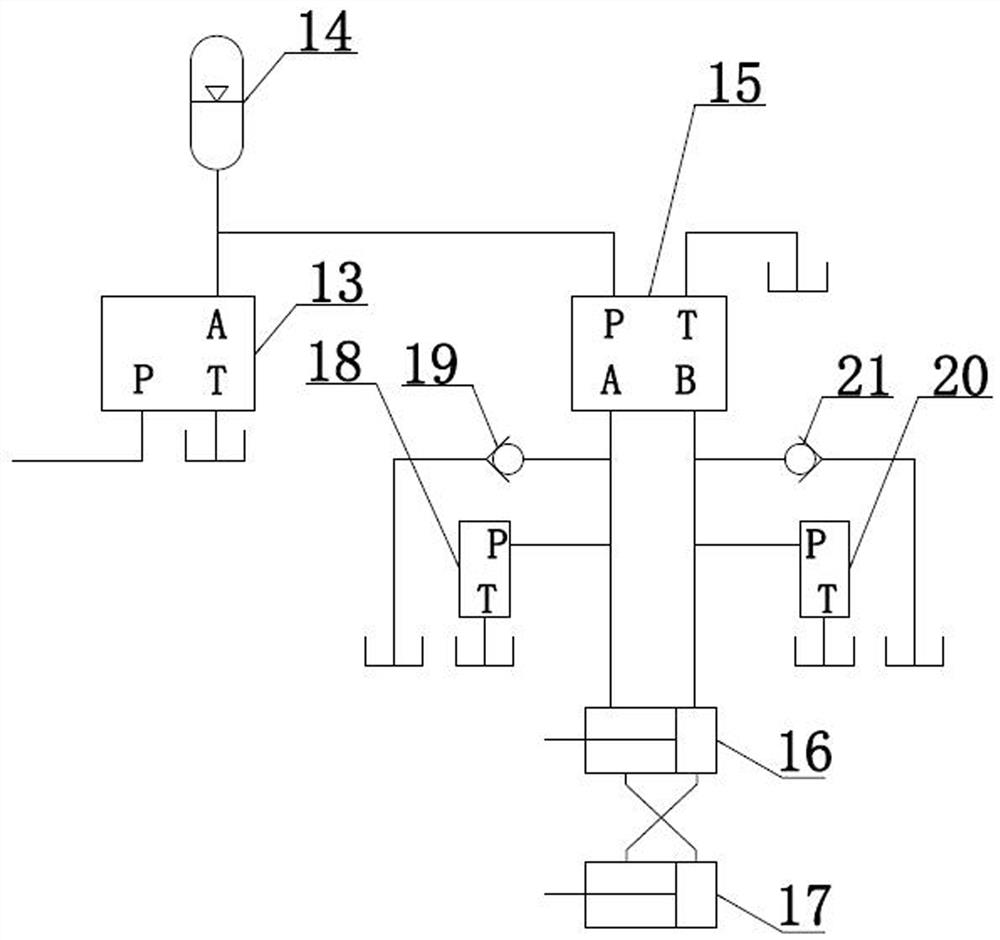

[0038] Such as figure 1 , an energy-saving and reliable hydraulic system of a scraper, including a power module, a brake hydraulic module 100 , a steering hydraulic module 200 and a lifting bucket working hydraulic module 300 , and also includes a steering sequence valve 12 and a working sequence valve 22 .

[0039] The power module includes an oil tank 1 containing hydraulic oil 2, a parallel hydraulic pump 4 for pumping the hydraulic oil 2, and a filter 3 and a connection between the oil tank 1 and the hydraulic pump 4. The main relief valve 5 at the output of the hydraulic pump 4 . When the P port pressure of the main relief valve 5 reaches 21 MPa, the main relief valve 5 is opened to ensure the safe operation of the hydraulic system.

[0040] The hydraulic pump 4 is a duplex plunger pump, which can be divided into two identical small hydraulic pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com