A Gear Fixture Suitable for Roughness Profiler

A gear fixture and profiler technology, used in instruments, measuring devices, etc., can solve the problems of difficult clamping, low measurement repeatability, and inability to evaluate all tooth profiles of gears at the same time, saving measurement time, increasing parameter range and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

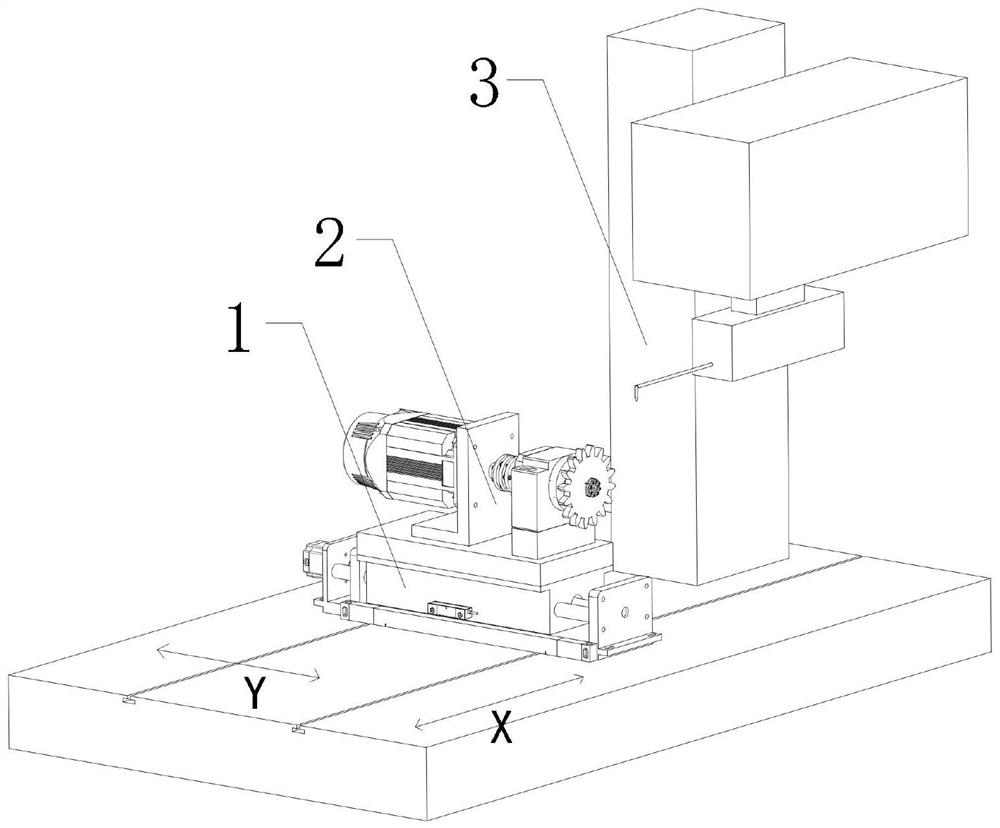

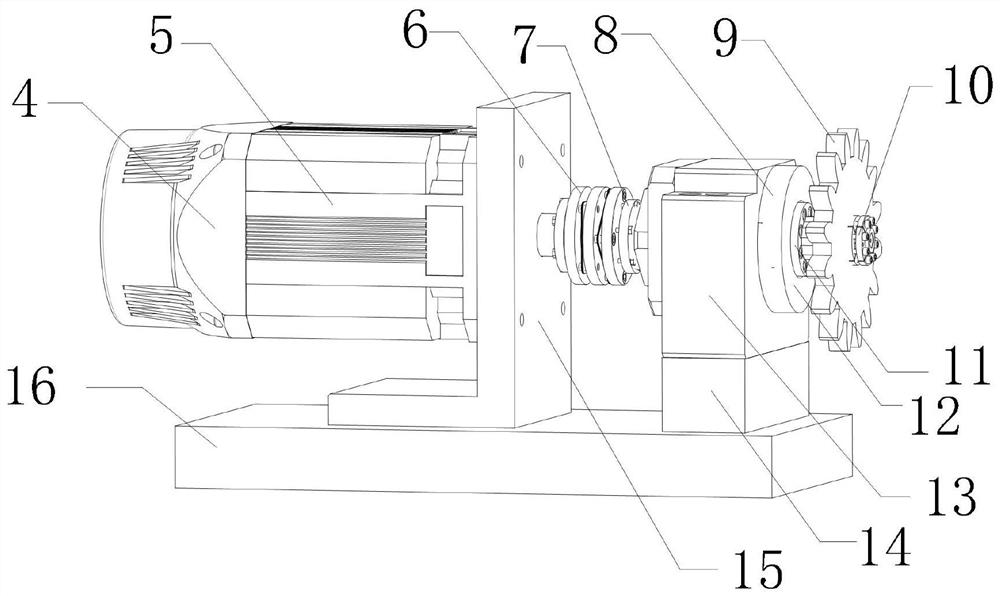

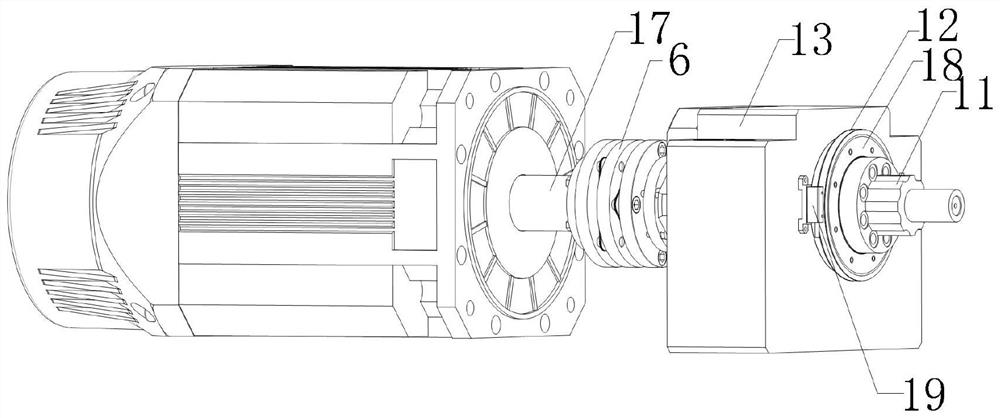

[0026] figure 1 It is a schematic diagram of the overall structure of the present invention. The gear fixture 2 is installed on the upper surface of the trapezoidal screw slider 22 of the linear sliding platform 1 , and the linear sliding platform 1 is placed on the marble workbench of the roughness profiler 3 . The gear fixture suitable for the roughness profiler is a gear fixture that can realize linear movement along the Y axis and rotational movement around the Y axis, and the movement direction and value of the fixture are controlled by a computer. Its measurement principle: the computer controls the motion of the two degrees of freedom of the fixture Y-axis and Y-axis rotation according to the parameters of the gear to be measured, adjust the fixture to make the probe produce the required measurement motion relative to the gear to be measured, and move the probe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com