LIBS online detection system for phosphate ore beneficiation system and application of LIBS online detection system

A detection system and technology for phosphate rock, applied in measurement devices, solid separation, instruments, etc., can solve the problems of poor quality stability of finished concentrates, long detection and analysis time, and the inability of analysis data to guide the adjustment of pharmaceutical parameters in a timely manner. The effect of sample analysis time, short detection time and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

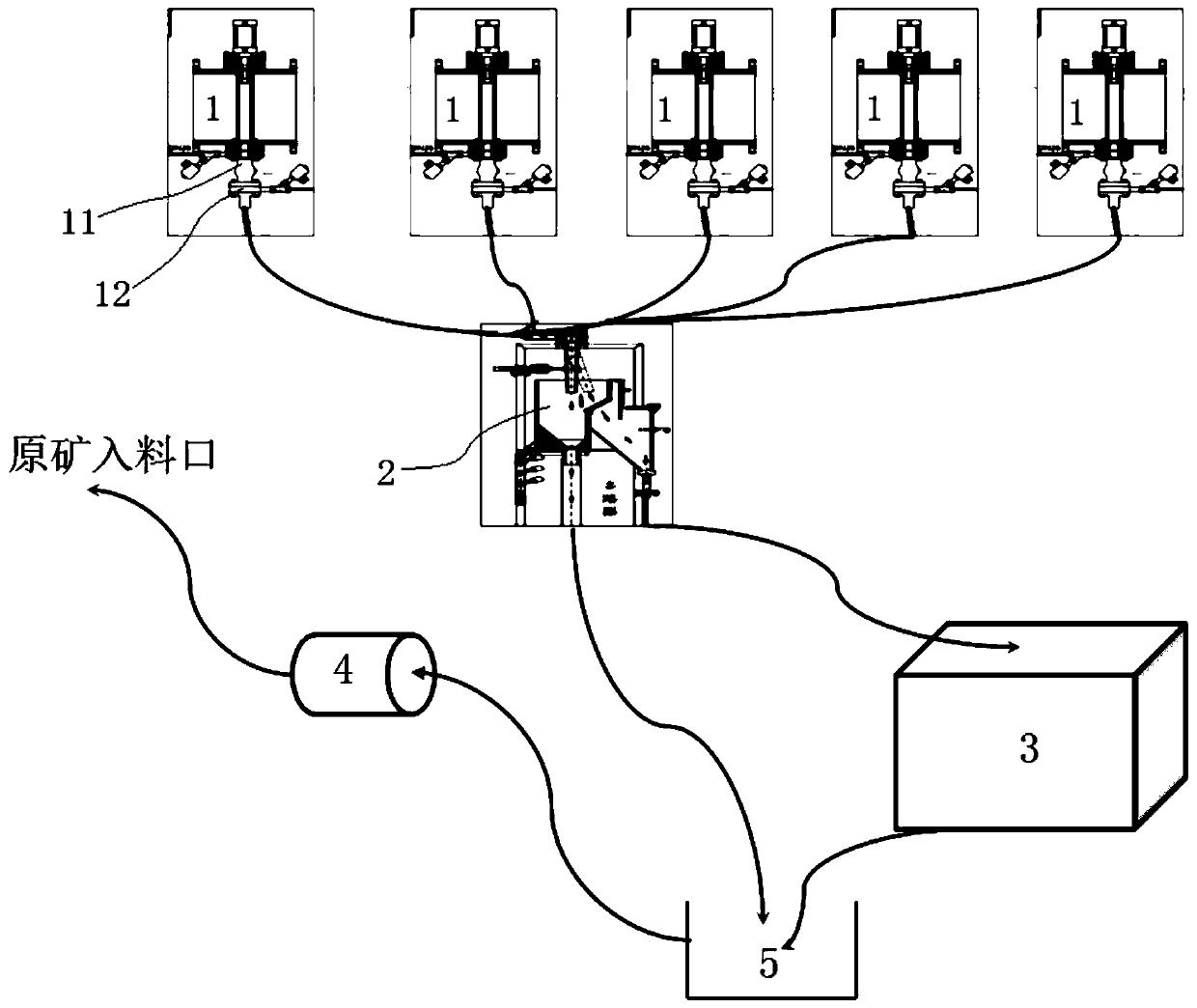

[0042] Such as image 3 A LIBS online detection system for phosphate ore beneficiation system is shown, the system is composed of sampler 1, multiplexer 2, LIBS analyzer 3, sand pump 4, liquid storage tank 5, DCS control system, sampling Device 1 communicates with the feed port of multi-channel divider 2 through pipelines, the sample outlet of multi-channel divider 2 communicates with the feed port of LIBS analyzer 3 through pipelines, and the sample outlet of multi-channel divider 2 communicates with the storage port through pipelines. The 5 feed ports of the liquid pool are connected, the 5 discharge ports of the liquid storage tank are connected with one end of the sand pump 4 through a pipeline, and the other end of the sand pump 4 is connected with the raw ore feed port through a pipeline; the 3 discharge ports of the LIBS analyzer are connected with the sand pump 4 through a pipeline. The liquid storage tank 5 is connected to the material inlet, the LIBS analyzer 3 is co...

Embodiment 2

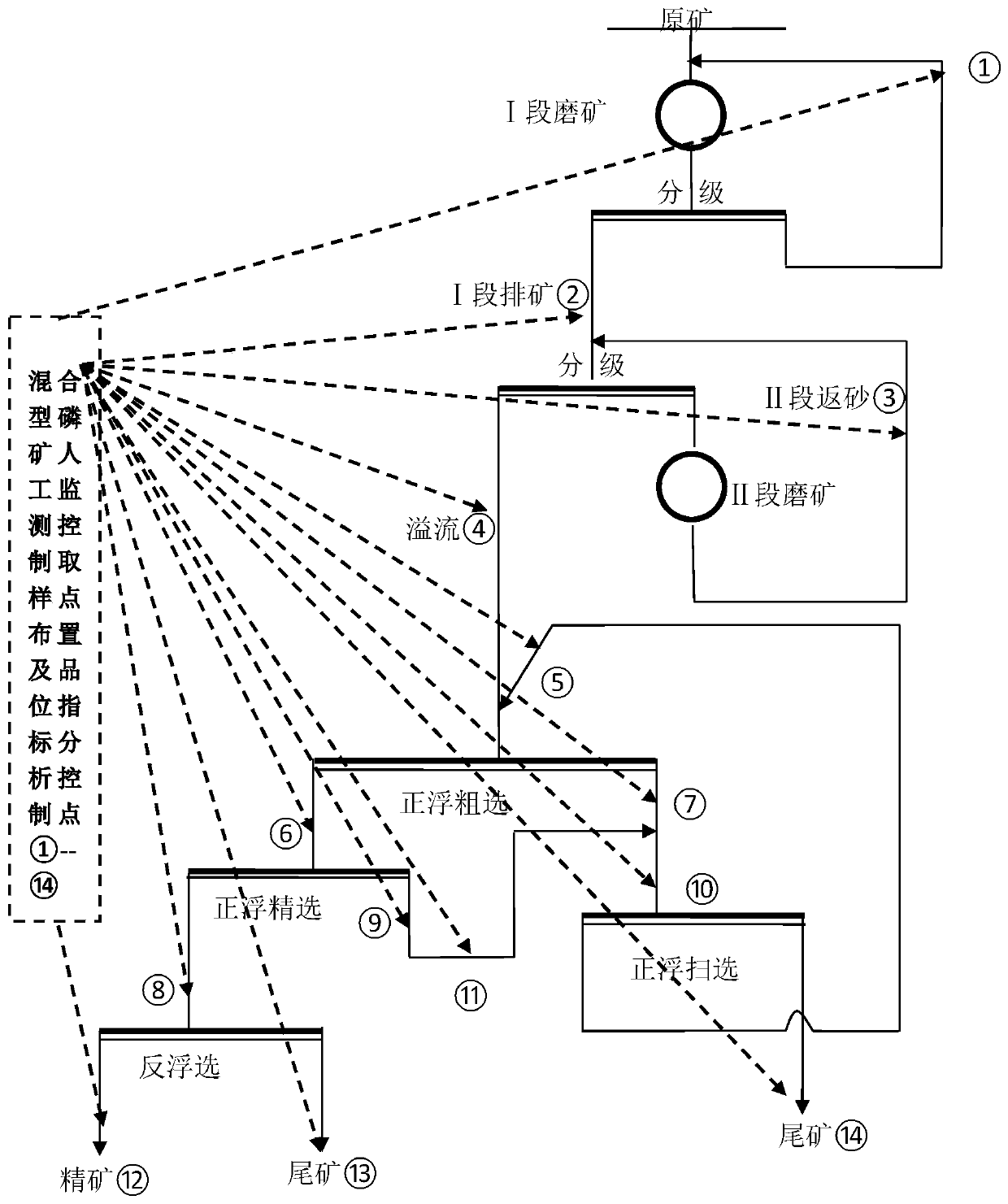

[0046] Such as Figure 4 As shown, the on-line detection system described in embodiment 1 is used for the positive-reverse flotation phosphate ore beneficiation system, and the low-grade collophanite of 1.5 million tons / year is processed (raw ore P 2 o 5 Grade 18~22%, MgO grade 4%~6%), its specific steps are as follows:

[0047] 1) Sampling: Sampling point ⑤ of raw ore in positive flotation, sampling point ⑧ of concentrated ore in positive flotation, and sampling point of tailings in positive flotation Reverse flotation concentrate sampling point Reverse flotation tailings sampling point The sampler 1 is set, and the control valves 11 of the sampler 1 at each sampling point are sequentially opened to take samples, and the samples obtained are pumped into the feed port of the multi-channel shrinker 2 through the pump 12;

[0048] 2) Sample preparation and analysis: After the multi-channel divider 2 divides, the small sample is sent to the LIBS analyzer 3 for online detec...

Embodiment 3

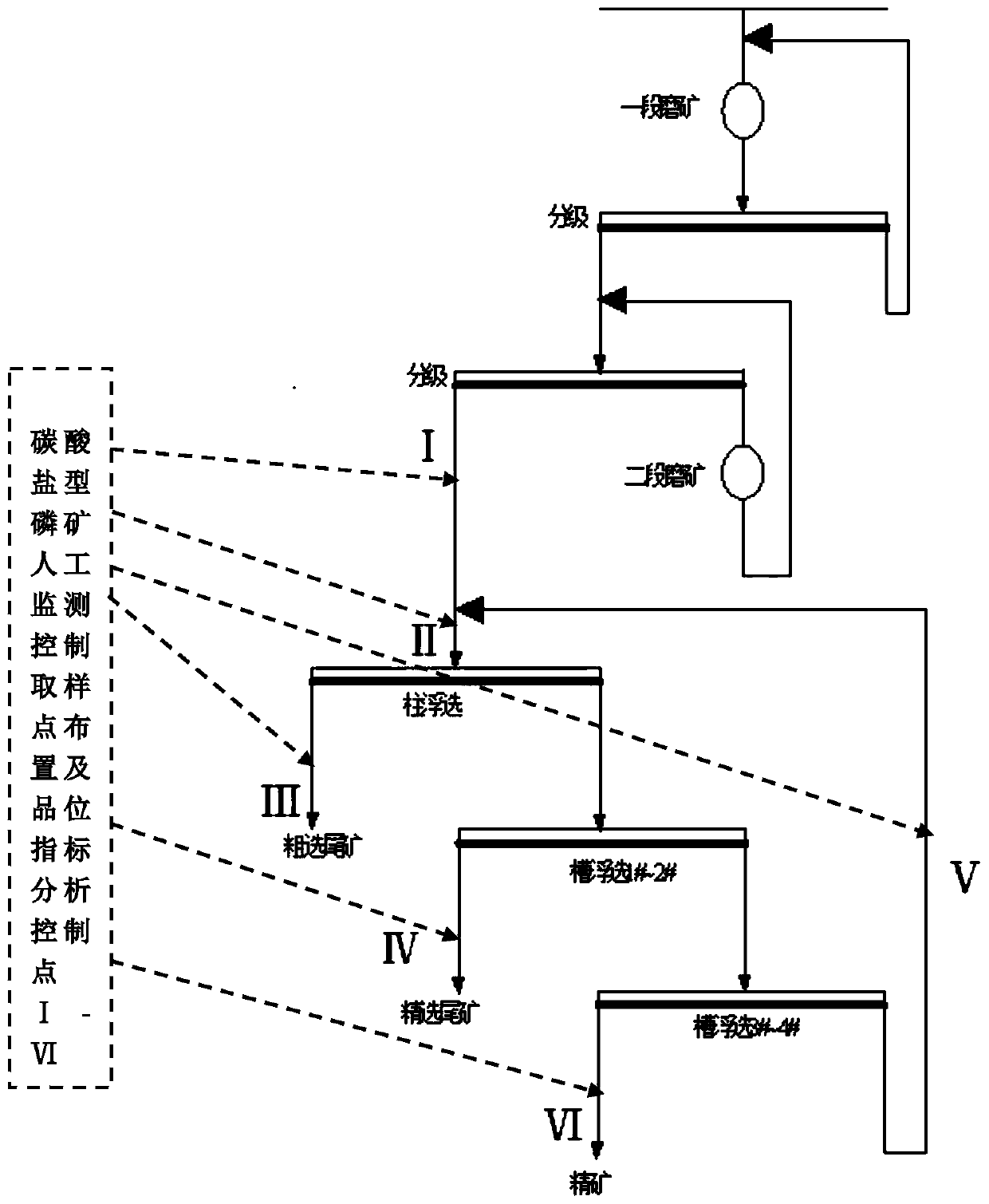

[0054] Such as Figure 5 As shown, the on-line detection system described in embodiment 1 is used for single reverse flotation phosphate ore beneficiation system, and the low-grade collophanite (raw ore P 2 o 5 Grade 18~22%, MgO grade 4%~6%), its specific steps are as follows:

[0055] 1) Sampling: Sampling is set at raw ore sampling point I, reverse flotation tailings sampling point III, reverse flotation beneficiation tailings sampling point IV, reverse flotation medium ore sampling point V, and reverse flotation tailings sampling point VI Open the control valve 11 of the sampler 1 at each sampling point in order to take samples in sequence, and the obtained sample is pumped into the feed port of the multi-channel shrinker 2 through the pump 12;

[0056] 2) Sample preparation and analysis: After the multi-channel divider 2 divides, the small sample is sent to the LIBS analyzer 3 for online detection and analysis of indicators, and the remaining materials are sent to the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com