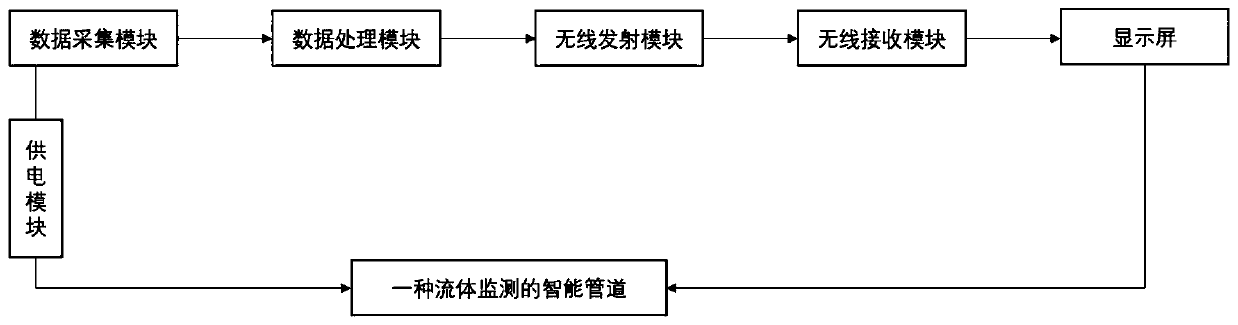

Intelligent pipeline for fluid monitoring

A technology of intelligent pipelines and pipelines, applied in fluid velocity measurement, pipeline systems, fluid dynamics tests, etc., can solve problems such as environmental pollution, economic losses, and small monitoring range, so as to avoid mutual interference, increase sensitivity, and ensure accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

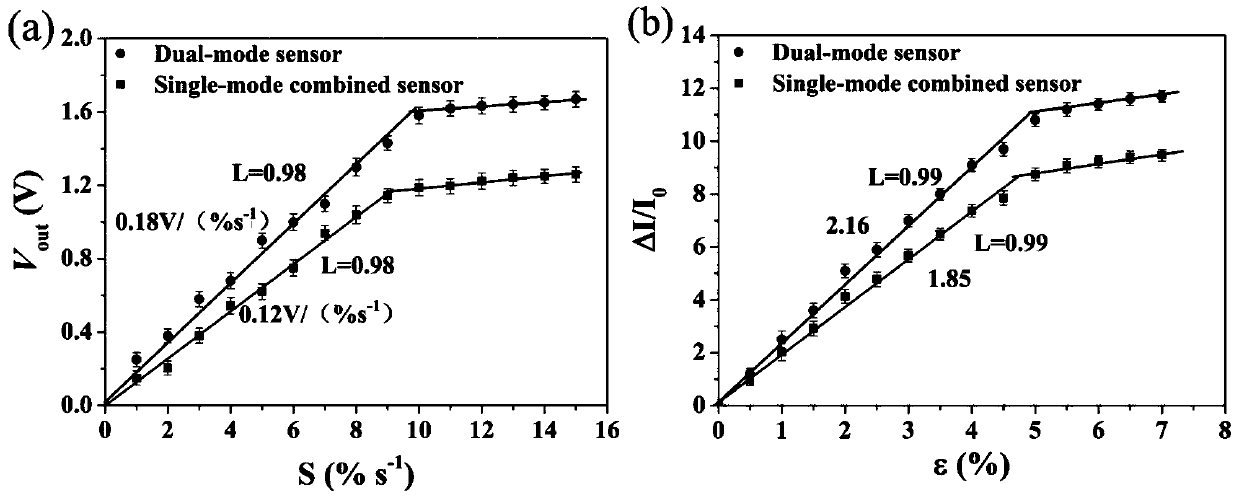

[0074] The data acquisition module of this embodiment is a piezoelectric / piezoresistive dual-mode flexible sensor, and its microarray structure adopts a pyramid-shaped microarray with a base length of 60 μm and a height of 40 μm. Such as figure 2 The shown piezoelectric / piezoresistive dual-mode pressure sensor includes a piezoelectric layer and a piezoresistive layer. Gold electrodes are prepared on the upper and lower sides of the piezoelectric layer, and the piezoelectric signal output by the piezoelectric layer is connected to a voltmeter through the gold electrodes. The surface of the microstructure of the piezoelectric layer and the piezoresistive layer is covered with a layer of rGO. The piezoresistive signal is input to the ammeter through two layers of rGO. The sensing signals of the piezoelectric layer and the piezoresistive layer are output through different electrodes, which avoids the mutual interference of the two sets of signals and ensures the accuracy of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com