Infrared polarizer with metal-medium-metal three-layer wire gating structure

A metal wire grid and infrared polarization technology, applied in polarizing components, instruments, optics, etc., can solve the lack of infrared polarizers and other problems, achieve the effect of wide spectrum and field of view, optimized polarization characteristics, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

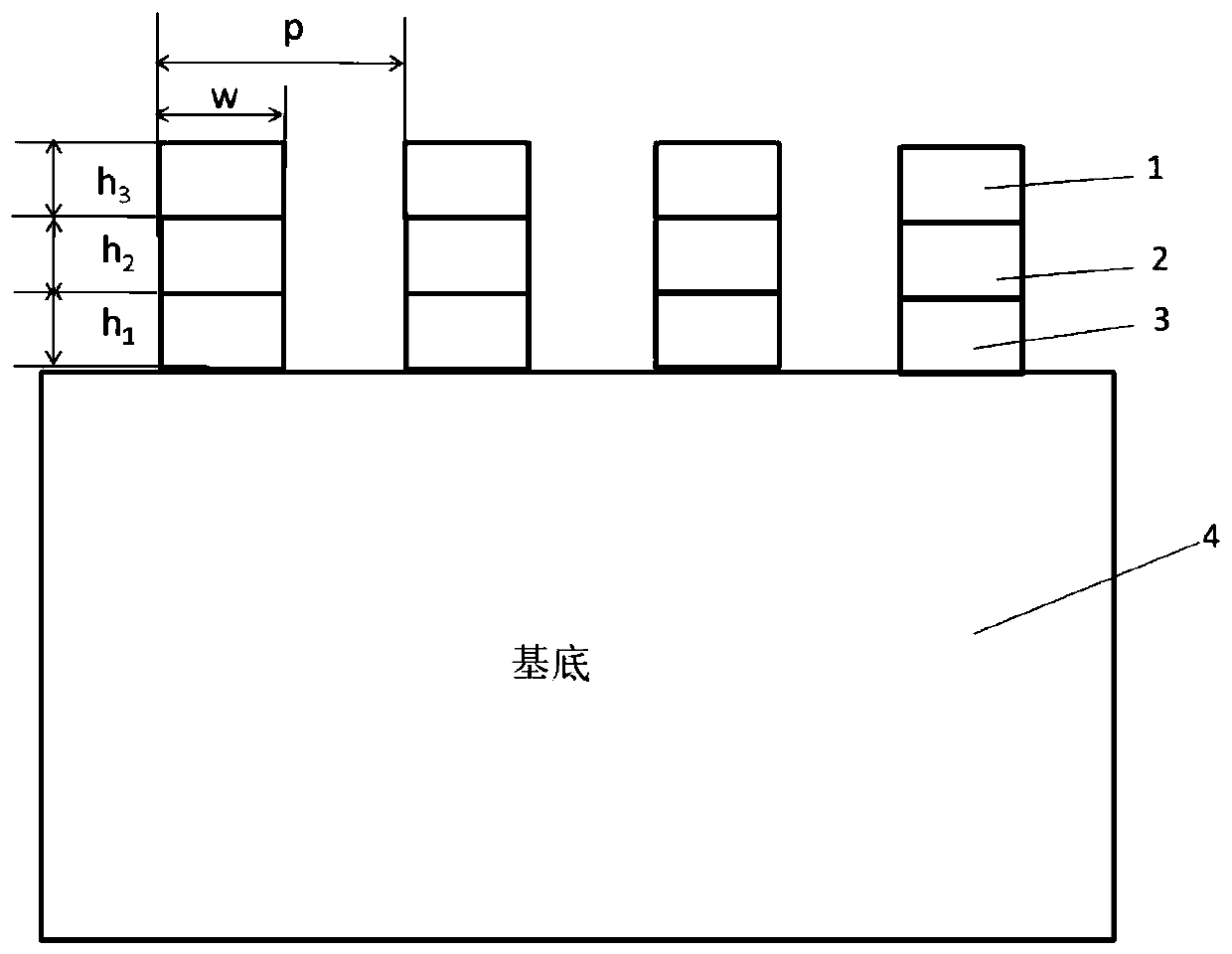

[0036] like figure 1 The structural schematic diagram of the infrared polarizer of the shown metal-medium-metal three-layer wire grid structure, the substrate 4 is sapphire (Al2 o 3 ), the incident light is 3-5 μm, and it is vertically incident. The low refractive index anti-reflection wire grid layer 2 is MgF 2 , the thickness h1 is 100nm, the material of the metal wire grid is Al, the period p is 500nm, the thickness h1=h2=h3=100nm, and the duty cycle is 0.5.

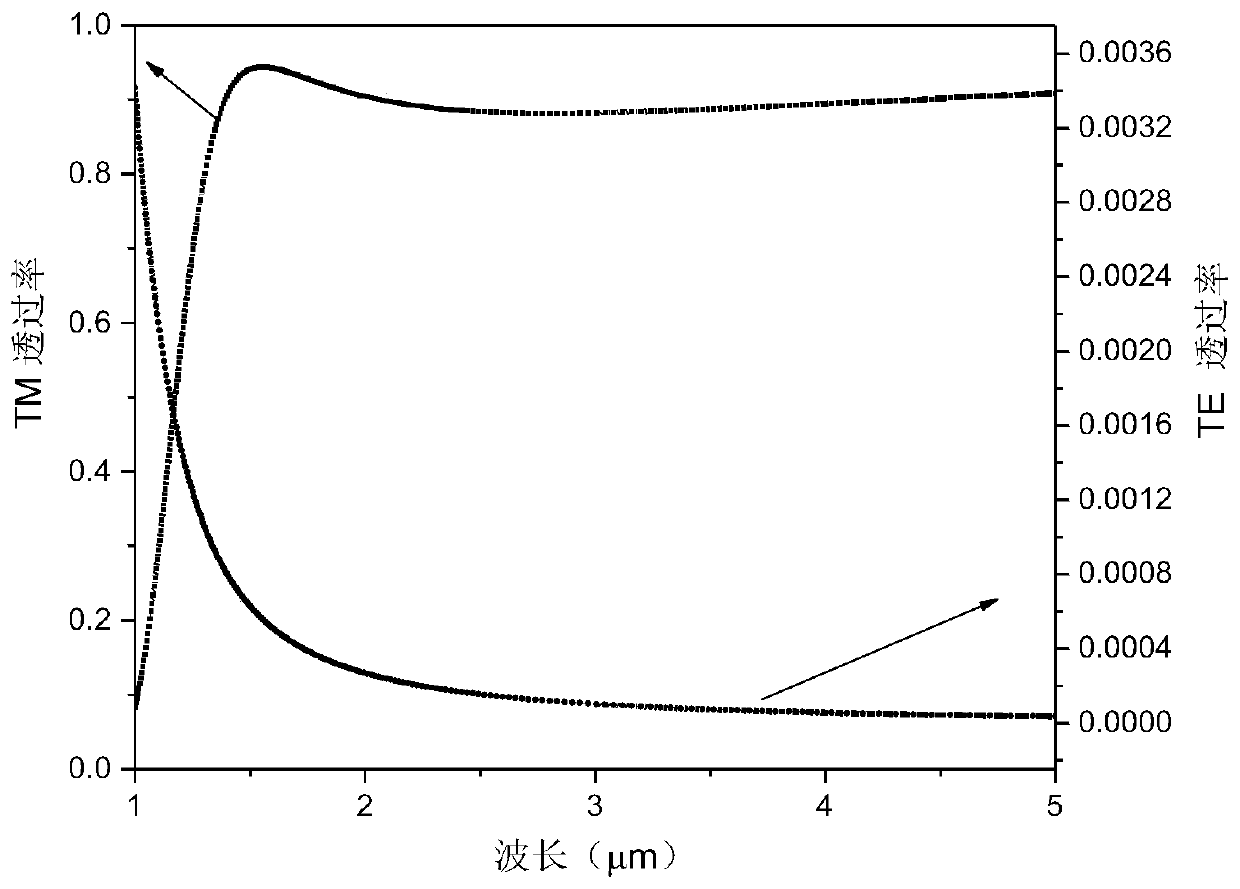

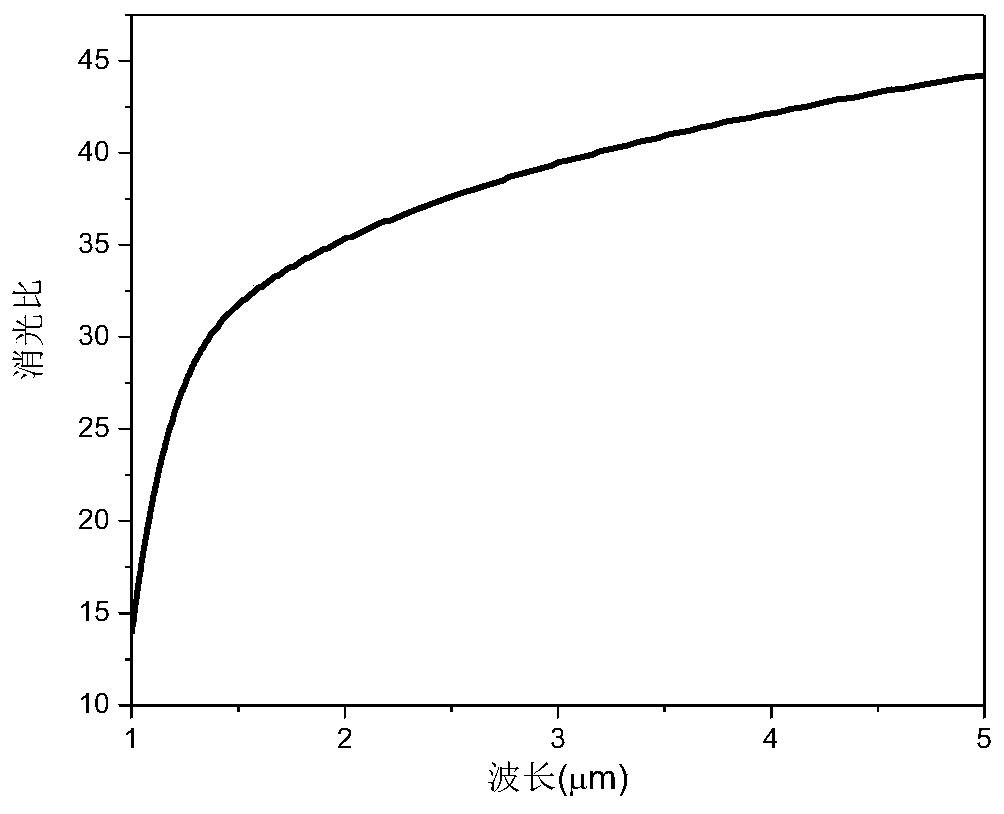

[0037] Under this structural condition, the relationship between TM and TE transmittance and the wavelength of incident light is as follows: figure 2 As shown, the relationship between the extinction ratio and the wavelength of the incident light is as image 3 As shown, at 4μm, the TM transmittance is 89.5%, the Te transmittance is 5.352E-5, and the extinction ratio is 42.2dB.

[0038] At the magnetic local resonance wavelength of 1.5 μm, the TM wave transmittance is at the peak position, and the transmittance i...

Embodiment 2

[0040] like figure 1 The structural schematic diagram of the infrared polarizer of the shown metal-medium-metal three-layer wire grid structure, the substrate 4 is sapphire (Al 2 o 3 ), the incident light is 3-5 μm, and it is vertically incident. The low refractive index anti-reflection wire grid layer 2 is SiO 2 , the thickness h2 is 60nm, the material of the metal wire grid is Ag, the period p is 300nm, the thickness h1=h3=100nm, and the duty cycle is 0.6.

[0041] Under this structural condition, the relationship between TM and TE transmittance and the wavelength of incident light is as follows: Figure 4 As shown, the relationship between the extinction ratio and the wavelength of the incident light is as Figure 5 As shown, at 4μm, the TM transmittance is 87.8%, the Te transmittance is 6.07E-4, and the extinction ratio is 51.6dB. At the magnetic local resonance wavelength of 1.4 μm, the TM wave transmittance is at the peak position, and the transmittance is 94%.

Embodiment 3

[0043] like figure 1 The schematic diagram of the structure of the infrared polarizer with the metal-dielectric-metal three-layer wire grid structure shown, the substrate is sapphire (Al 2 o 3 ), the incident light is 3-5 μm, and it is vertically incident. The low refractive index anti-reflection wire grid layer 2 is TiO 2 , the thickness h2 is 140nm, the material of the metal wire grid is Au, the period p is 400nm, the thickness h1=h3=100nm, and the duty cycle is 0.7.

[0044] Under this structural condition, the relationship between TM and TE transmittance and the wavelength of incident light is as follows: Figure 6 As shown, the relationship between the extinction ratio and the wavelength of the incident light is as Figure 7 As shown, at 4μm, the TM transmittance is 94.2%, the Te transmittance is 1.61E-2, and the extinction ratio is 37.7dB. At the magnetic local resonance wavelength of 1.9 μm, the TM wave transmittance is at the peak position, and the transmittance i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com