High-efficiency probe capable of breaking through diffraction limit and preparation method of high-efficiency probe

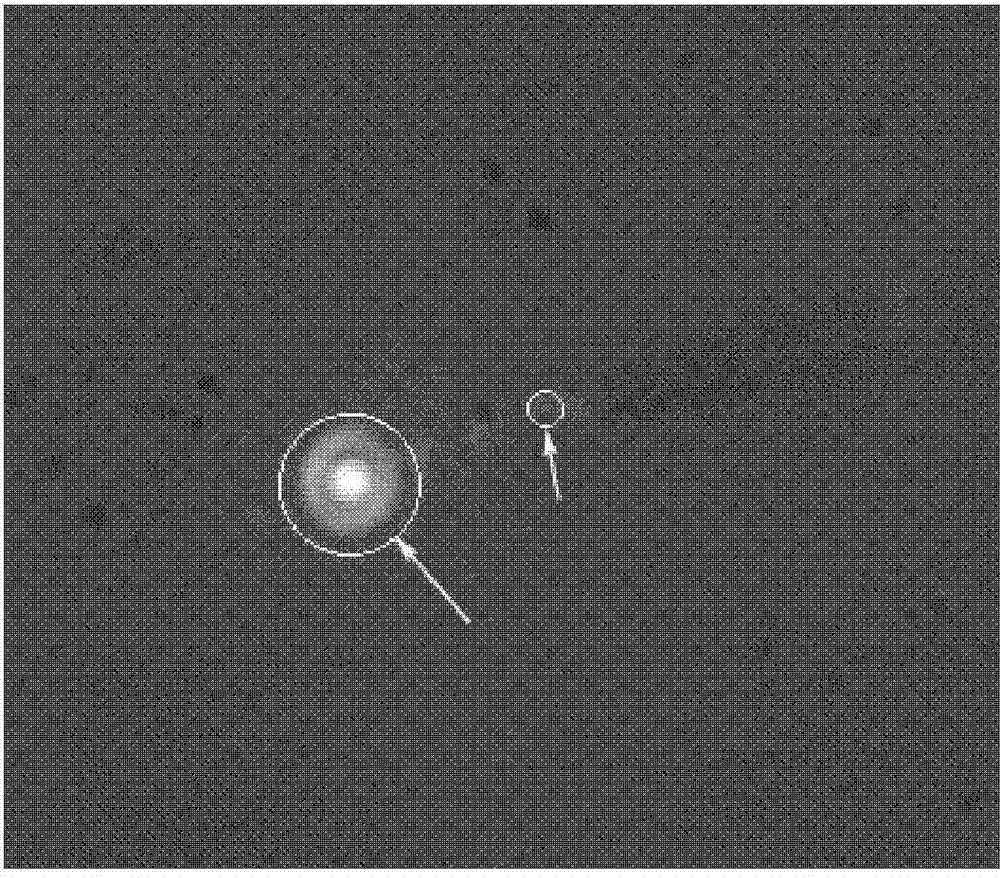

A probe and fiber cone technology, applied in the field of excimers, can solve the problems of low light transmittance and low probe collection efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

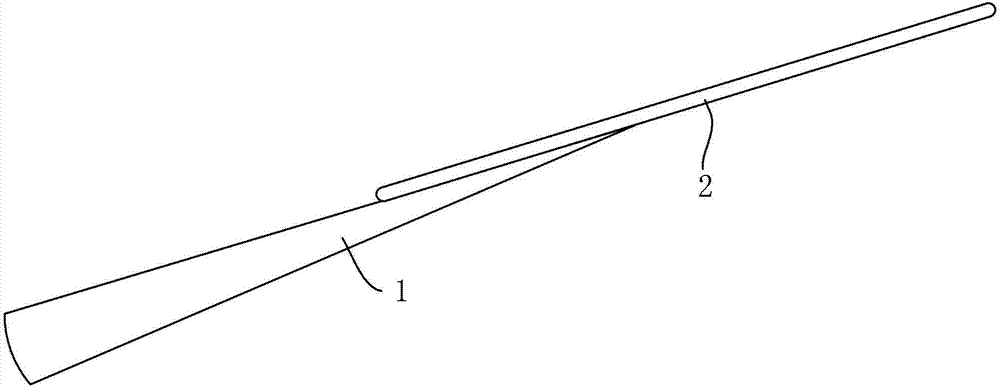

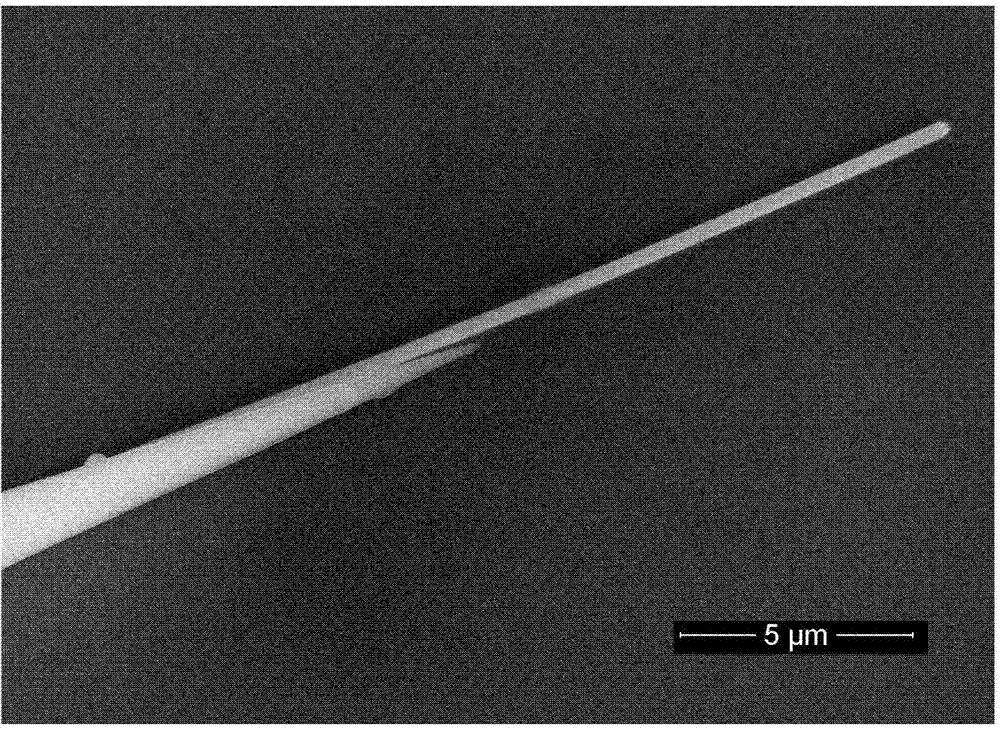

[0031] The preparation method of the probe of the present invention comprises:

[0032] S1. Preparation of optical fiber cones and conductive nanowires.

[0033] S2. Taking a conductive nanowire of a specific length, and fixing it at the end of the fiber taper.

[0034] In the above preparation method, the method for preparing the optical fiber taper and the conductive nanowire in step S1 can adopt the existing technology. Step S2 can also be performed by using existing micro-assembly technology. For example, on the three-dimensional micro-nano translation stage, glue is first dispensed on the fiber taper, and then the conductive nanowire is moved to a fixed position and is in contact with the glue. After the glue dries, the inventable probe can be obtained. However, it should be noted that the present invention does not exclude the use of other methods to fix the fiber taper and the conductive nanowire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com