Preparation method for collagen nanowire array layer cuvette

A nanowire array and collagen technology, applied in the field of improvement of cuvettes, to achieve the effect of easy operation, good hydrophilic performance, and good polarization characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a cuvette with a collagen nanowire array layer, the specific steps are as follows:

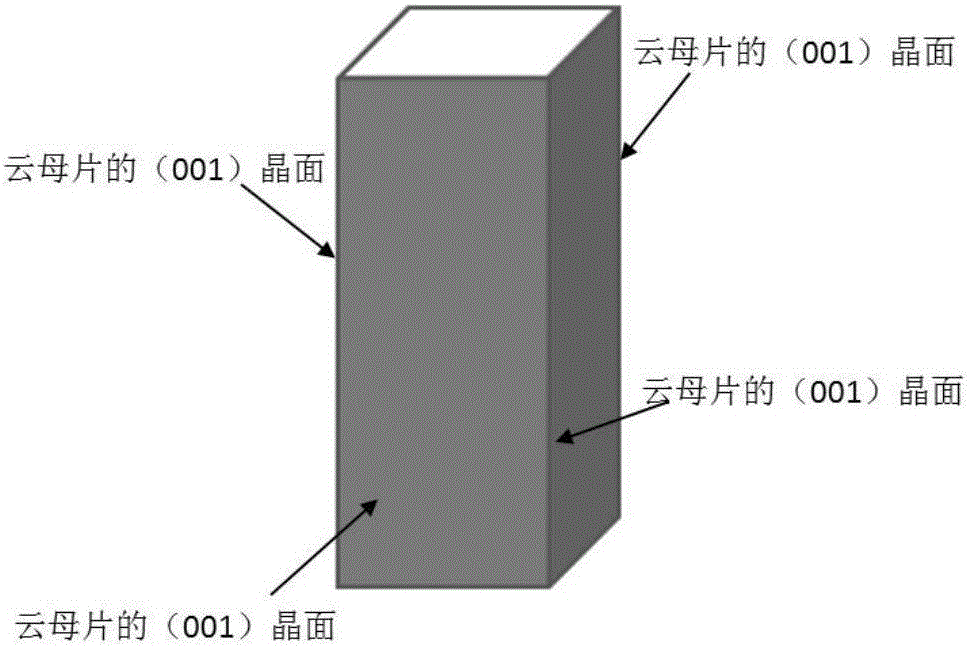

[0025] Step 1, make the mica sheet into a cuvette structure, stick the corner of the mica sheet with adhesive tape and tear off the upper layers to expose the smooth mica sheet;

[0026] Step 2, prepare the Na of 0.2mol / L 2 HPO 4 and 0.3mol / L NaH 2 PO 4 solution, the Na 2 HPO 4 solution with NaH 2 PO 4 The solutions were mixed to prepare a buffer solution with pH=6.8, and a 5 μg / ml collagen monomer solution was prepared with sodium phosphate buffer;

[0027] Step 3, evenly titrate the collagen solution on the mica sheet, and wash the mica sheet with buffer after 15-20 minutes;

[0028] Step 4: Titrate the buffer solution on the cleaned mica sheet, cover the mica sheet, incubate for 12 hours, wash with water, and dry naturally to obtain a cuvette with a collagen nanowire array layer.

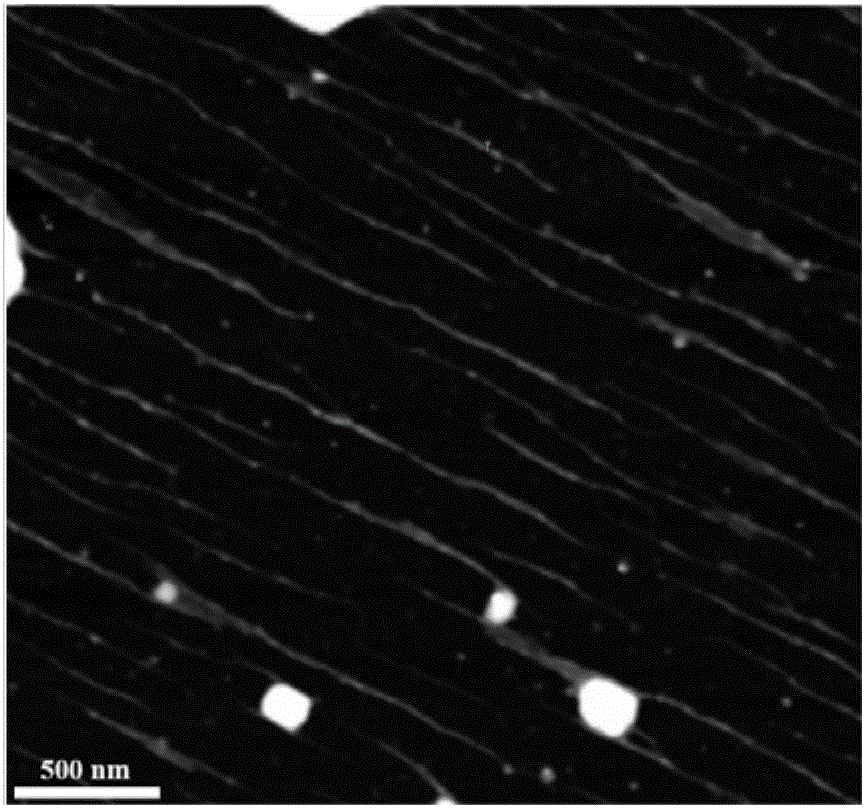

[0029] AFM observation of the self-assembled structure of collagen on m...

Embodiment 2

[0031] A method for preparing a cuvette with a collagen nanowire array layer, the specific steps are as follows:

[0032] Step 1, make the mica sheet into a cuvette structure, stick the corner of the mica sheet with adhesive tape and tear off the upper layers to expose the smooth mica sheet;

[0033] Step 2, prepare the Na of 0.2mol / L 2 HPO 4 and 0.3mol / L NaH 2 PO 4 solution, the Na 2 HPO 4 solution with NaH 2 PO 4 The solutions were mixed to prepare a buffer solution with pH=7, and a 10 μg / ml collagen monomer solution was prepared with sodium phosphate buffer;

[0034] Step 3, evenly titrate the collagen solution on the mica sheet, and wash the mica sheet with buffer after 15-20 minutes;

[0035] Step 4: Titrate the buffer solution on the cleaned mica sheet, cover the mica sheet, incubate for 12 hours, wash with water, and dry naturally to obtain a cuvette with a collagen nanowire array layer.

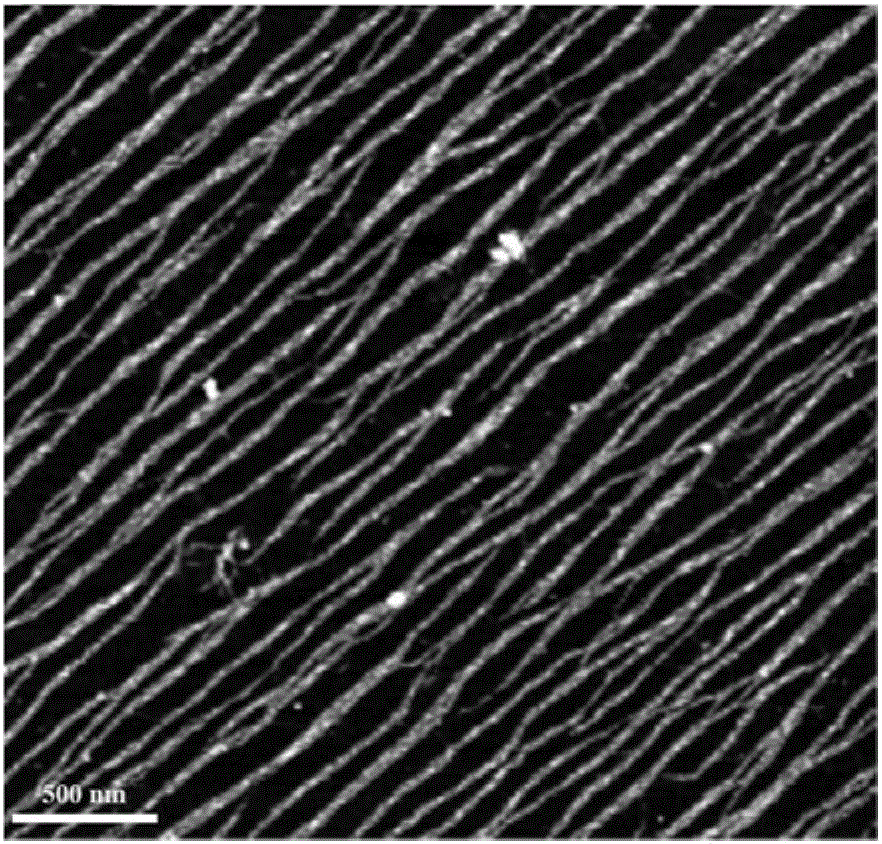

[0036] AFM observation of the self-assembled structure of collagen on mi...

Embodiment 3

[0040] A method for preparing a cuvette with a collagen nanowire array layer, the specific steps are as follows:

[0041] Step 1, make the mica sheet into a cuvette structure, stick the corner of the mica sheet with adhesive tape and tear off the upper layers to expose the smooth mica sheet;

[0042] Step 2, prepare the Na of 0.2mol / L 2 HPO 4 and 0.3mol / L NaH 2 PO 4 solution, Na 2 HPO 4 solution with NaH 2 PO 4 The solutions were mixed to prepare a buffer solution with pH=8, and a 10 μg / ml collagen monomer solution was prepared with sodium phosphate buffer;

[0043] Step 3, evenly titrate the collagen solution on the mica sheet, and wash the mica sheet with buffer after 15-20 minutes;

[0044] Step 4: Titrate the buffer solution on the cleaned mica sheet, cover the mica sheet, incubate for 12 hours, wash with water, and dry naturally to obtain a cuvette with a collagen nanowire array layer.

[0045] Selected Area Diffraction (SAED) of TEM was carried out on the mica s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com