Manufacture method of depletion mode metal-oxide-semiconductor field effect transistor (MOSFET)

A manufacturing method and depletion-type technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as inability to manufacture high-quality depletion-type MOSFETs and inaccurate channel depth control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

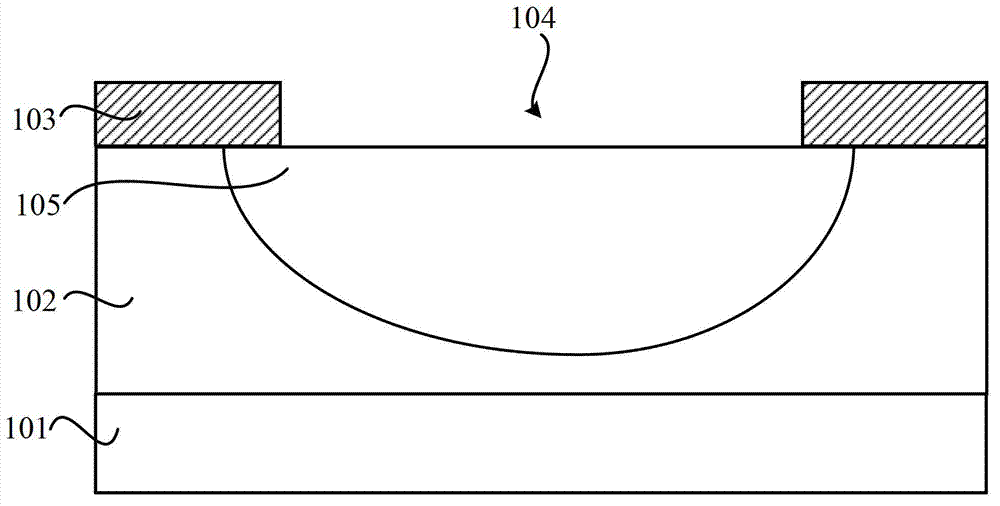

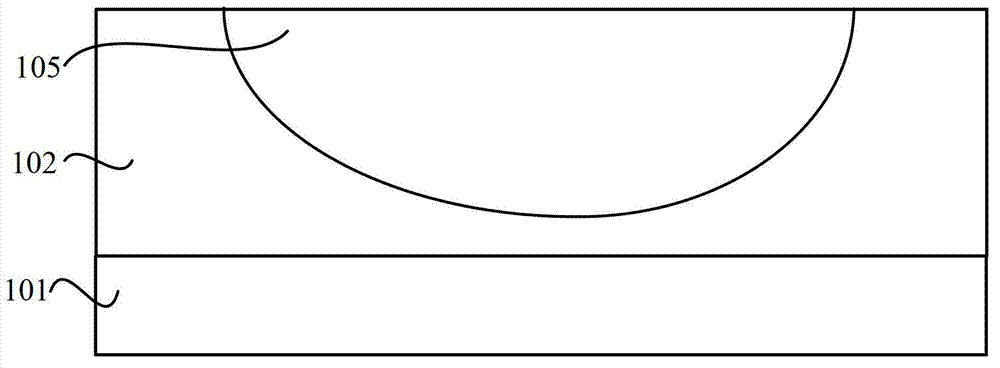

[0026] The core idea of the present invention is to use the mask layer to perform ion implantation to realize the channel of the depletion MOSFET. By using the mask layer, the position and structure of the channel can be precisely controlled, and the channel can be precisely controlled by adjusting the conditions of ion implantation. parameters such as depth and doping concentration. Precise trench structure, location, and depth enable high-performance depletion-mode MOSFETs.

[0027] In order to make the purpose, technical solution and advantages of the present invention more clear, the following will be further described in detail in conjunction with the accompanying drawings.

[0028] Such as Figure 7 As shown, the depletion MOSFET in one embodiment of the present invention includes: an N-type substrate 101; an N-type epitaxial layer 102 formed on one side of the substrate 101; a P-type epitaxial layer 102 formed in the N-type epitaxial layer 102 Doped deep well 105; N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com