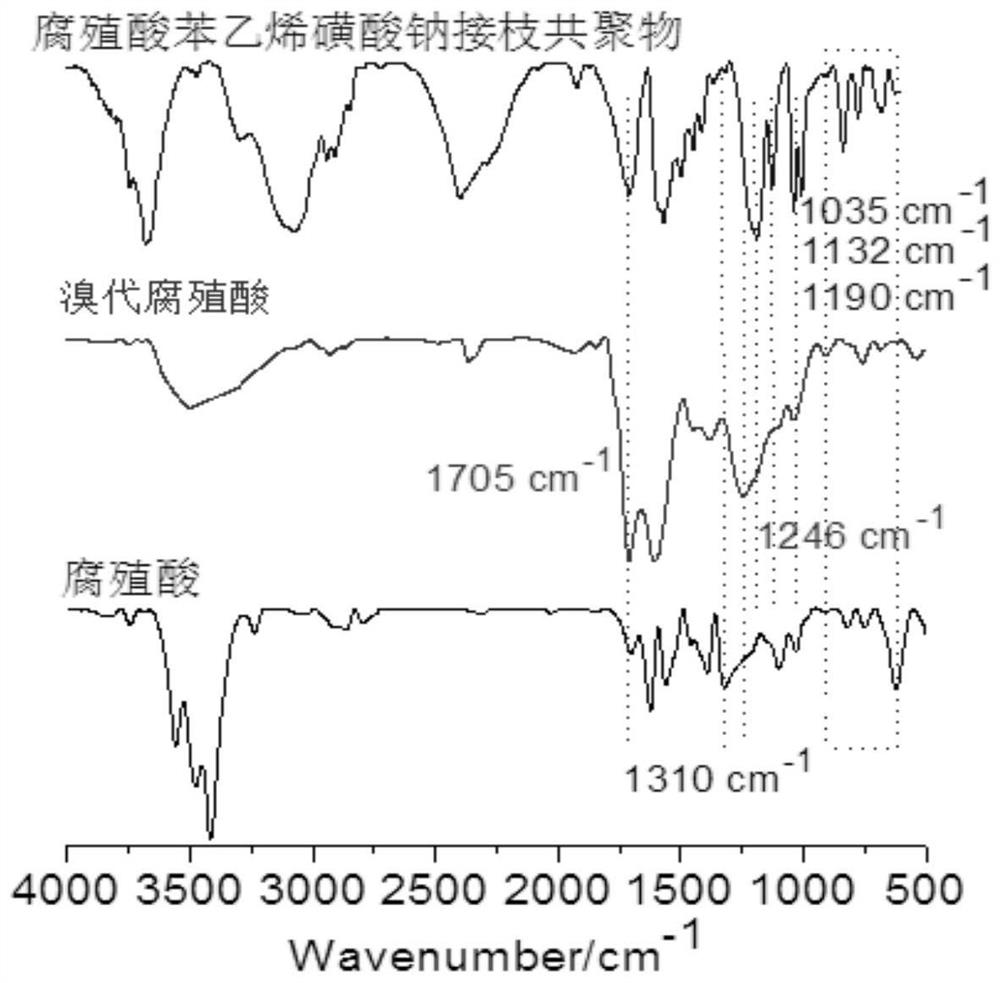

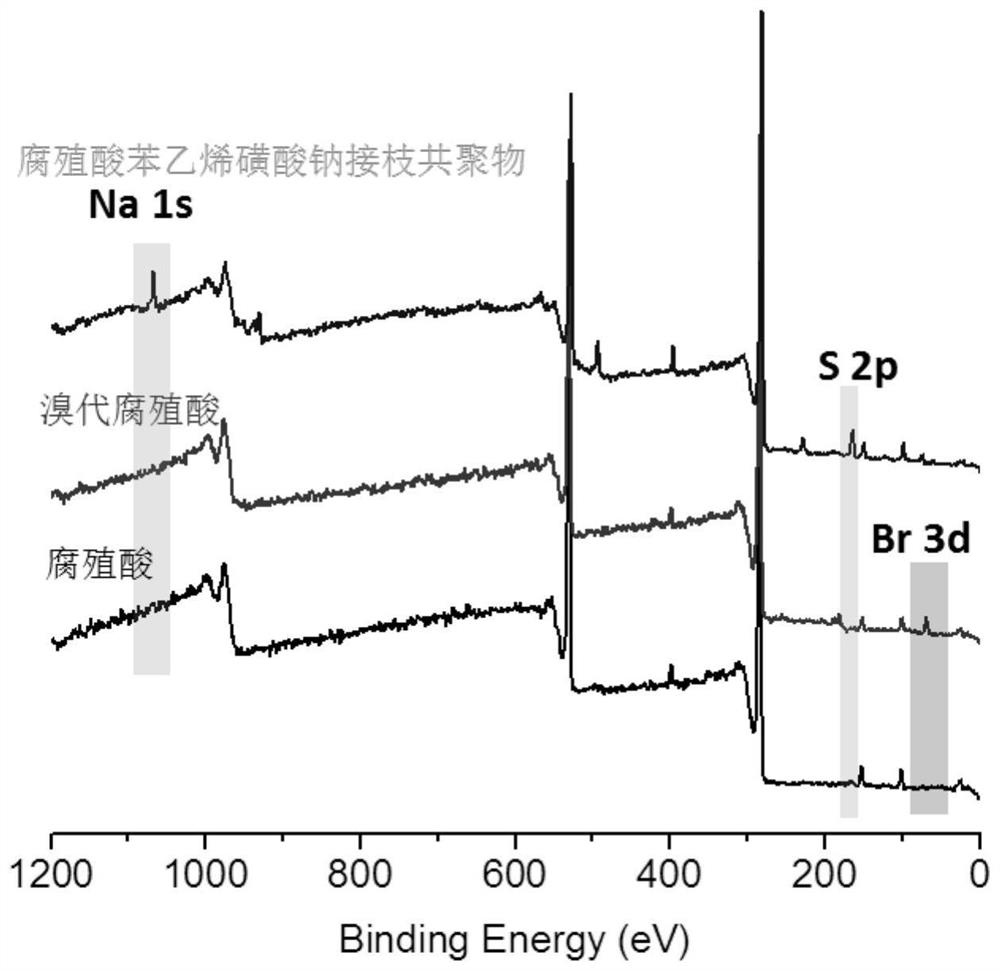

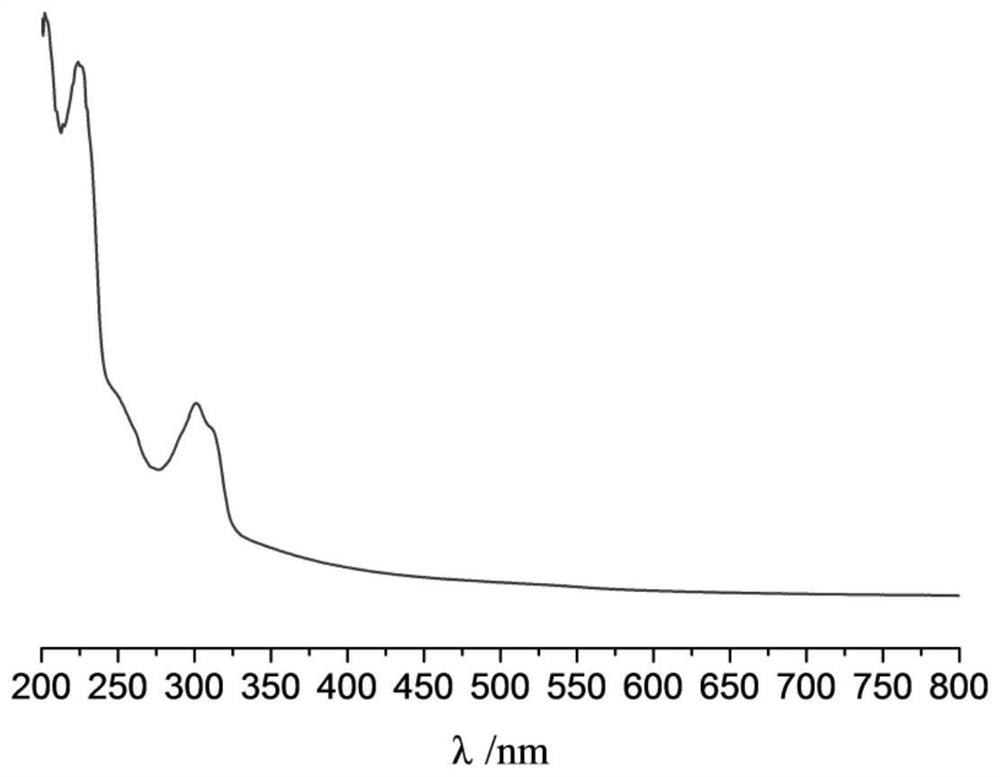

A kind of preparation method of humic acid styrene sulfonate sodium graft copolymer coal water slurry dispersant

A technology of sodium styrene sulfonate and graft copolymer, which is used in fuels, liquid carbon-containing fuels, petroleum industry, etc. Promote adsorption, improve dispersion and viscosity reduction effect, and improve the effect of charge repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Disperse 10 g of humic acid in 20 mL of dichloromethane (26.5 g), add 3.08 g of triethylamine to the dispersion system, and move the system into a low temperature and constant temperature reaction bath, and the temperature of the reaction bath is 0°C. After the temperature equilibrated, 7 g of bromoisobutyryl bromide was added dropwise, and the dropwise addition continued for 0.5 hours. After the dropwise addition, the system was removed, and the reaction was continued at room temperature for 5 hours. After the reaction, filter with suction, and wash the filter residue with deionized water until it is neutral, and obtain the brominated humic acid macromolecular initiator after drying.

[0033] (2) Dissolve 10g of brominated humic acid initiator, 10.89g of 2,2-bipyridine, and 10g of sodium styrene sulfonate monomer in water, adjust the pH value of the solution to 10 with sodium hydroxide, and pass through the system Nitrogen for 15 minutes, and quickly add 5 g of cu...

Embodiment 2

[0036] (1) Disperse 10 g of humic acid in 30 mL of dichloromethane (39.75 g), add 7 g of triethylamine to the dispersion system, and move the system into a low temperature and constant temperature reaction bath, and the temperature of the reaction bath is 0°C. After the temperature equilibrated, 14 g of bromoisobutyryl bromide was added dropwise, and the dropwise addition continued for 0.5 hours. After the dropwise addition, the system was removed, and the reaction was continued at room temperature for 5 hours. After the reaction, filter with suction, and wash the filter residue with deionized water until it is neutral, and obtain the brominated humic acid macromolecular initiator after drying.

[0037] (2) Dissolve 10g of brominated humic acid initiator, 10.89g of 2,2-bipyridine, and 100g of sodium styrene sulfonate monomer in water, adjust the pH value of the solution to 10 with potassium hydroxide, and pass through the system Nitrogen for 15 minutes, and quickly add 5 g of...

Embodiment 3

[0040] (1) Disperse 10 g of humic acid in 20 mL of dichloromethane (26.5 g), add 3.08 g of triethylamine to the dispersion system, and move the system into a low temperature and constant temperature reaction bath, and the temperature of the reaction bath is 0°C. After the temperature equilibrated, 7 g of bromoisobutyryl bromide was added dropwise, and the dropwise addition continued for 0.5 hours. After the dropwise addition, the system was removed, and the reaction was continued at room temperature for 5 hours. After the reaction, filter with suction, and wash the filter residue with deionized water until it is neutral, and obtain the brominated humic acid macromolecular initiator after drying.

[0041] (2) Dissolve 10g of brominated humic acid initiator, 9.47g of 2,2-bipyridine, and 20g of sodium styrene sulfonate monomer in water, adjust the pH value of the solution to 10 with sodium hydroxide, and pass through the system Nitrogen for 15 minutes, and quickly add 3g of cupr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com