Semiconductor component packaging method and alignment mold thereof

A packaging method and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of inaccurate alignment, derivation, and increased installation costs of light-emitting diodes, and achieve the effect of improving packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

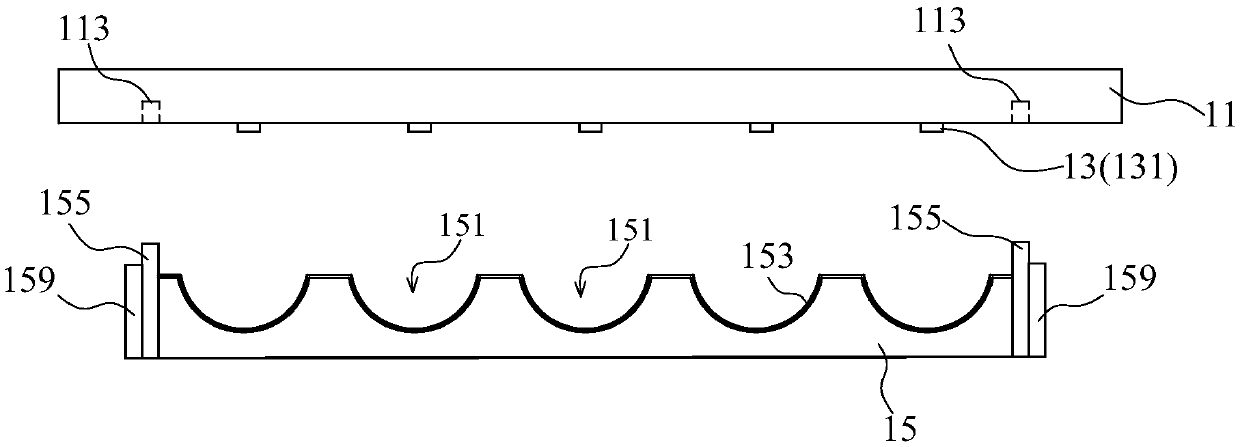

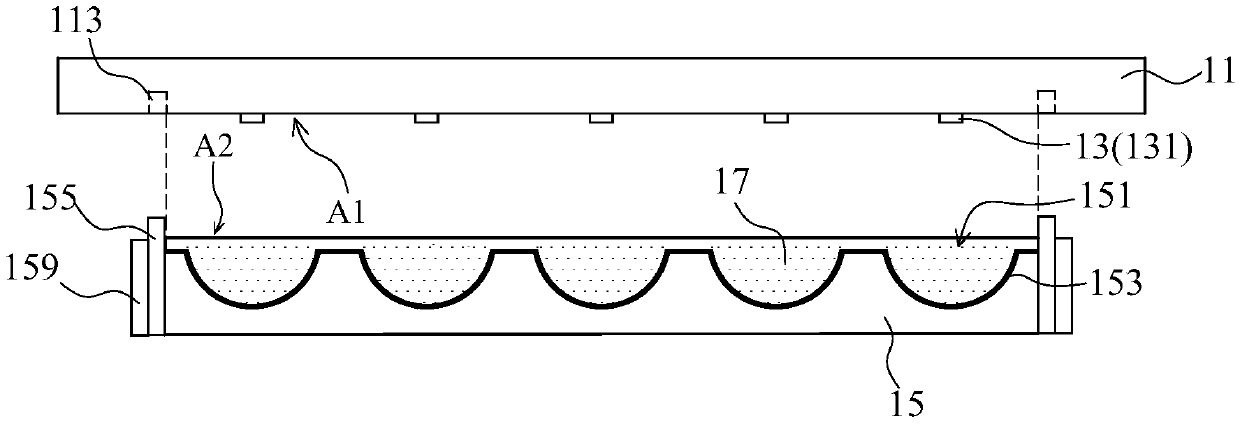

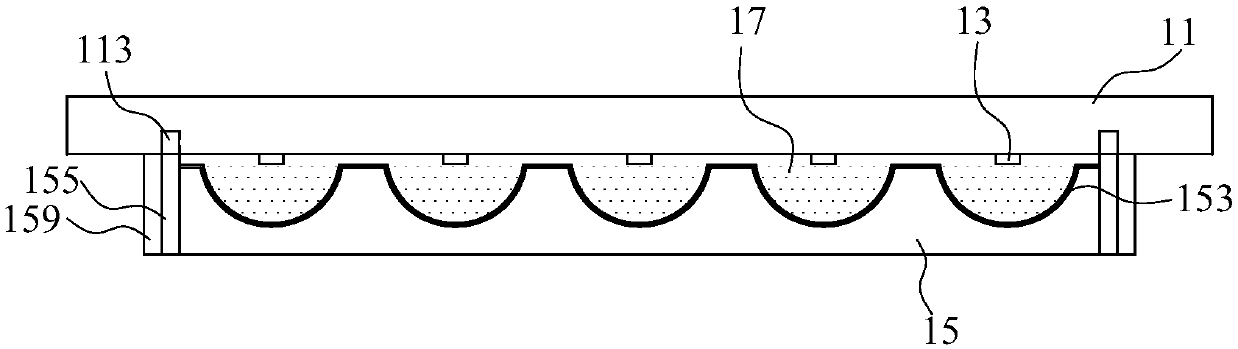

[0031] See Figure 1 to Figure 4 , Respectively are side views of an embodiment of the semiconductor device packaging method of the present invention in each step. As shown in the figure, first, a plurality of semiconductor elements 13 are arranged on a surface of a substrate 11, and a mold 15 is prepared. The mold 15 has a plurality of molding cavities 151, such as figure 1 Shown. The substrate 11 may be a silicon (Si) substrate, alumina (A 2 O 3 ) Substrate, aluminum nitride (AlN) substrate, sapphire substrate, silicon carbide (SiC) substrate, gallium arsenide (GaAs) substrate, glass substrate (Glass), circuit board (PCB) or ceramic substrate.

[0032] Specifically, the semiconductor elements 13 arranged on the surface of the substrate 11 may be arranged in any form, for example, arranged on a surface of the substrate 11 in a matrix. The semiconductor element 13 may be a light-emitting diode die, a semiconductor chip, etc., taking the light-emitting diode die 131 as an example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com