Industrial equipment operation monitoring signal adjusting circuit

A technology for operation monitoring and industrial equipment, applied in the field of circuits, can solve problems such as inability to guarantee image quality and large attenuation of high-frequency components, and achieve the effects of ensuring accuracy, overcoming attenuation of high-frequency components, and preventing signal crossover distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

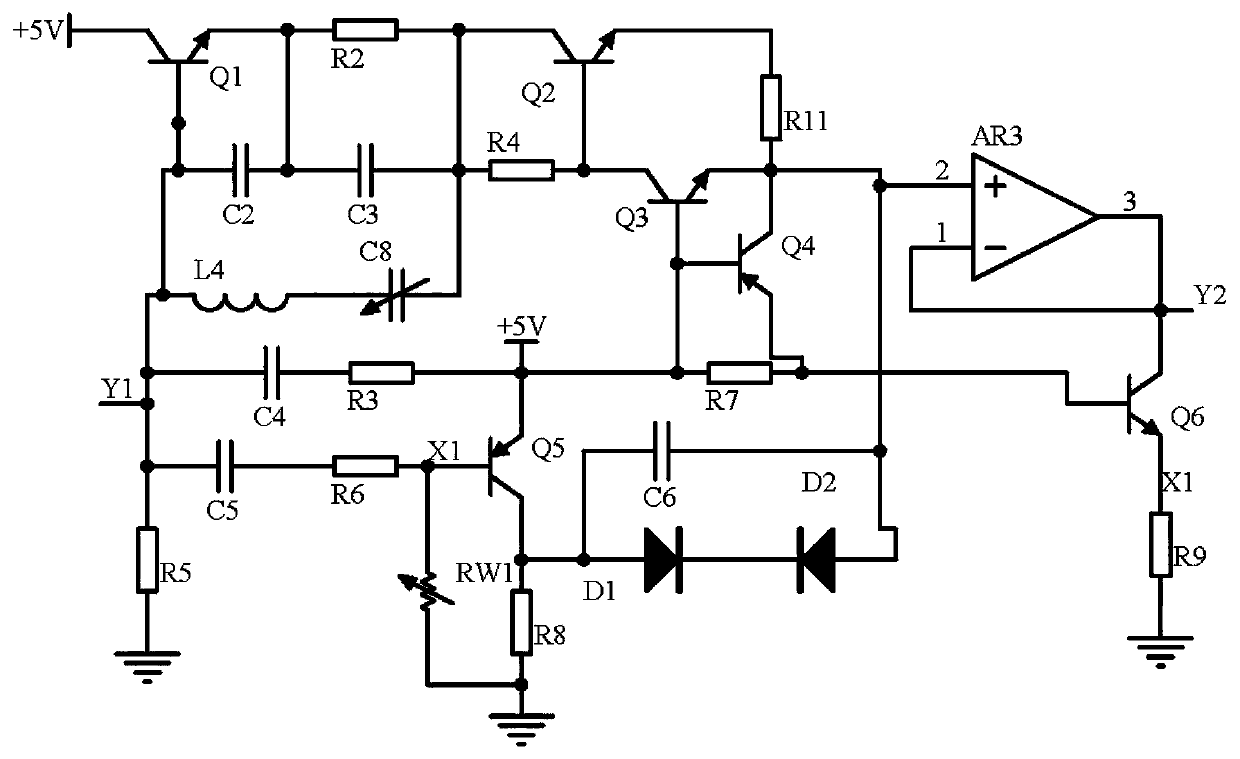

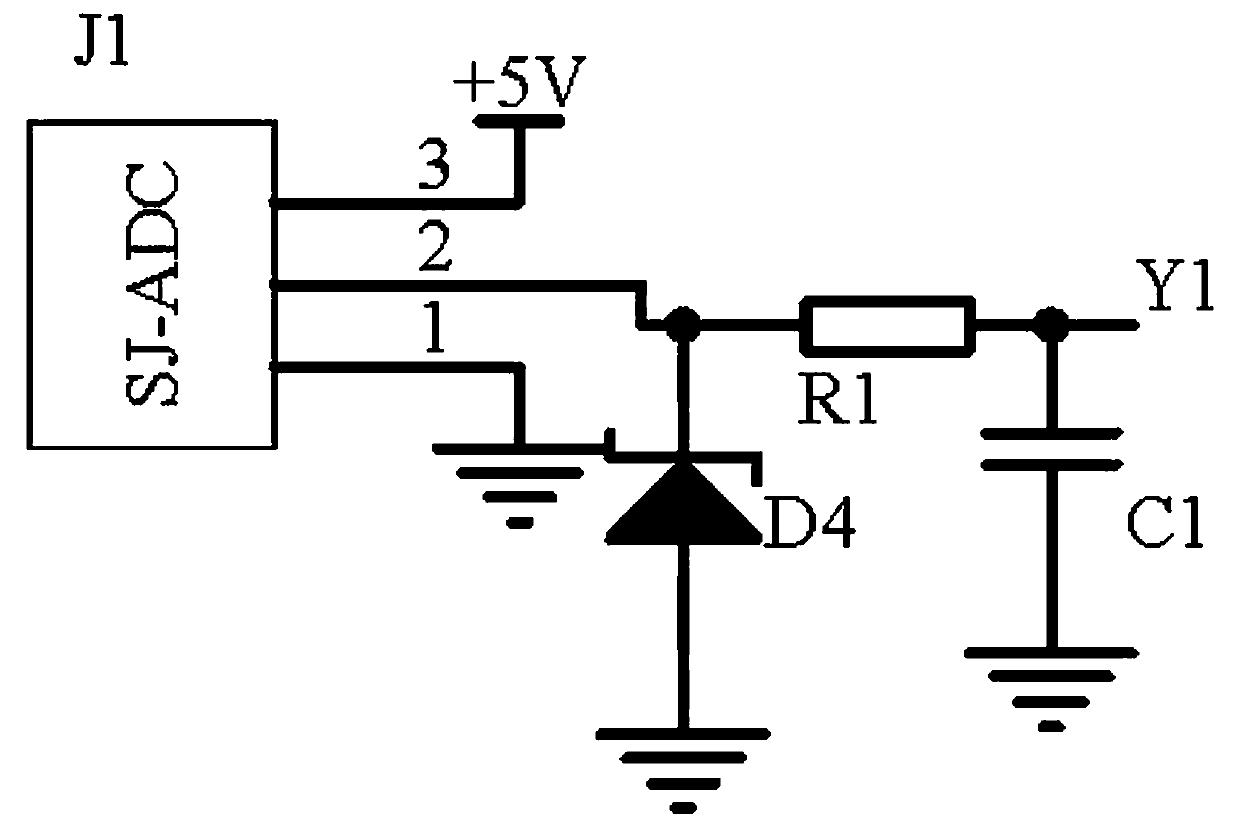

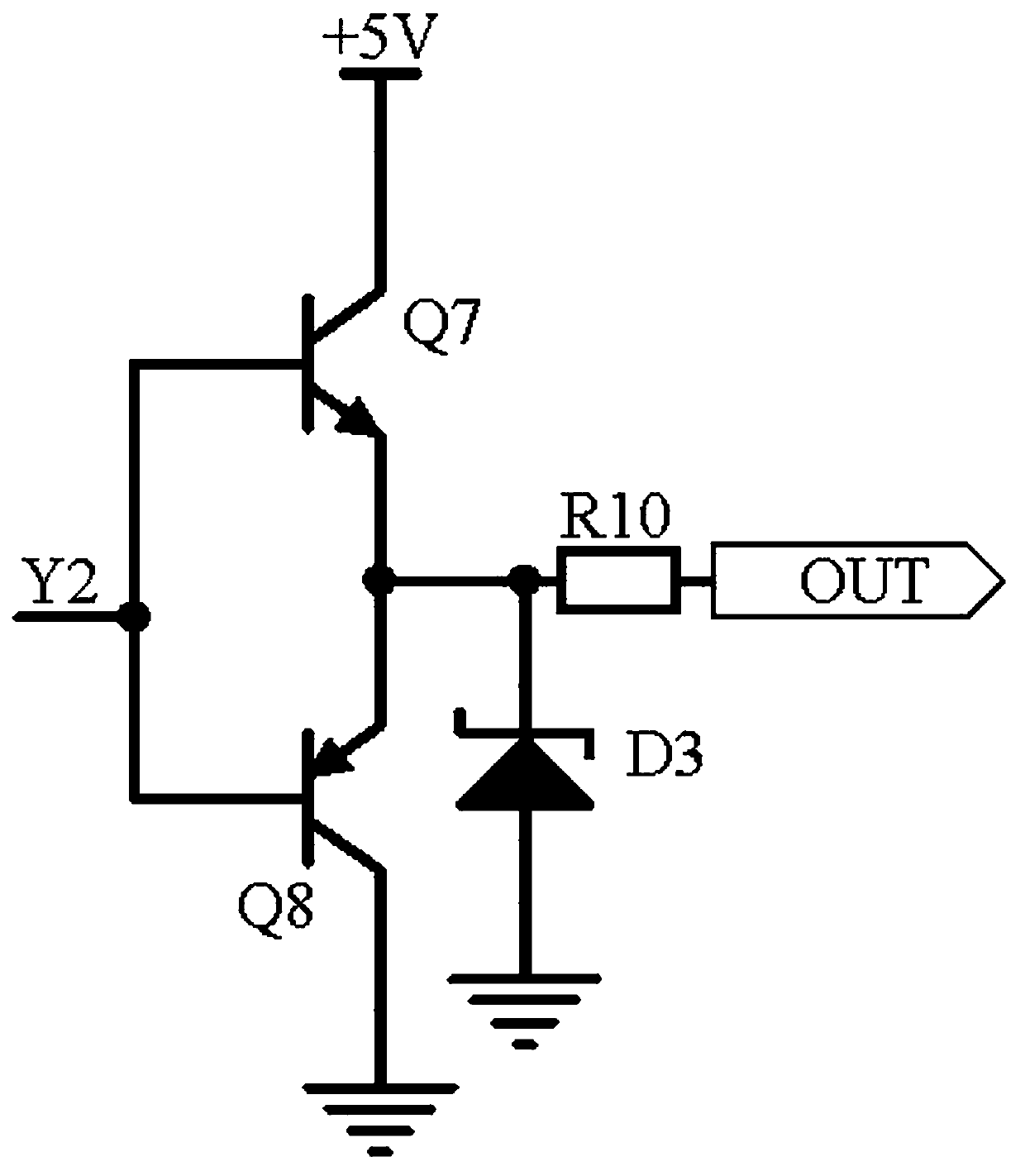

[0011] Regarding the aforementioned and other technical contents, features and effects of the present invention, refer to the appended figure 1 to attach image 3 It will be apparent from the detailed description of the embodiments. The structural contents mentioned in the following embodiments are all based on the accompanying drawings of the description.

[0012] An industrial equipment operation monitoring signal adjustment circuit, including a frequency acquisition circuit, a separation switch circuit, and a push-pull output circuit; the frequency acquisition circuit collects the frequency of an analog signal received by an industrial equipment operation monitoring control terminal, and the separation switch circuit uses a triode Q5 and can Variable resistor RW1, capacitor C4, and capacitor C5 form a synchronous separation circuit to divide the signal into two signals of the same frequency and different amplitudes. One circuit uses capacitor C2, capacitor C3, inductor L4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com